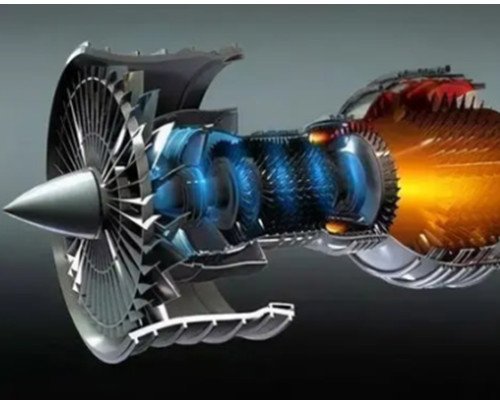

High-temperature alloys are a type of metal material based on iron, nickel and cobalt, which can work for a long time at high temperatures above 600°C and under certain stresses, and have excellent comprehensive properties. According to the matrix elements, they can be mainly divided into iron-based high-temperature alloys, nickel-based high-temperature alloys and cobalt-based high-temperature alloys, which are mainly used to manufacture turbine blades, guide blades and turbine disks for aviation, ships and industrial gas turbines.

High-temperature alloys are the most difficult materials to process among all kinds of difficult-to-cut materials. They have the following processing difficulties:

(1) They have high resistance to plastic deformation and severe work hardening, which results in large cutting forces, which are 2-3 times greater than those of ordinary steels.

(2) They have poor thermal conductivity and the temperature remains high during cutting, causing the tool to wear rapidly.

(3) Chips adhere to the cutting edge surface of the tool, which easily produces built-up edge, affecting the surface quality of the workpiece being processed.

High-temp alloys like Inconel and titanium are tough to machine. More Superhard offers carbide, ceramic, and CBN cutting tools to meet these challenges with high efficiency and durability.

Material: Inconel 718 (HRC45-47)

Tool: CBN Insert RGN120400

Speed: 350 m/min | Feed: 0.15 mm/rev | Depth: 0.5 mm

Result: Surface roughness Ra0.3–0.4 with excellent finish and tool life.