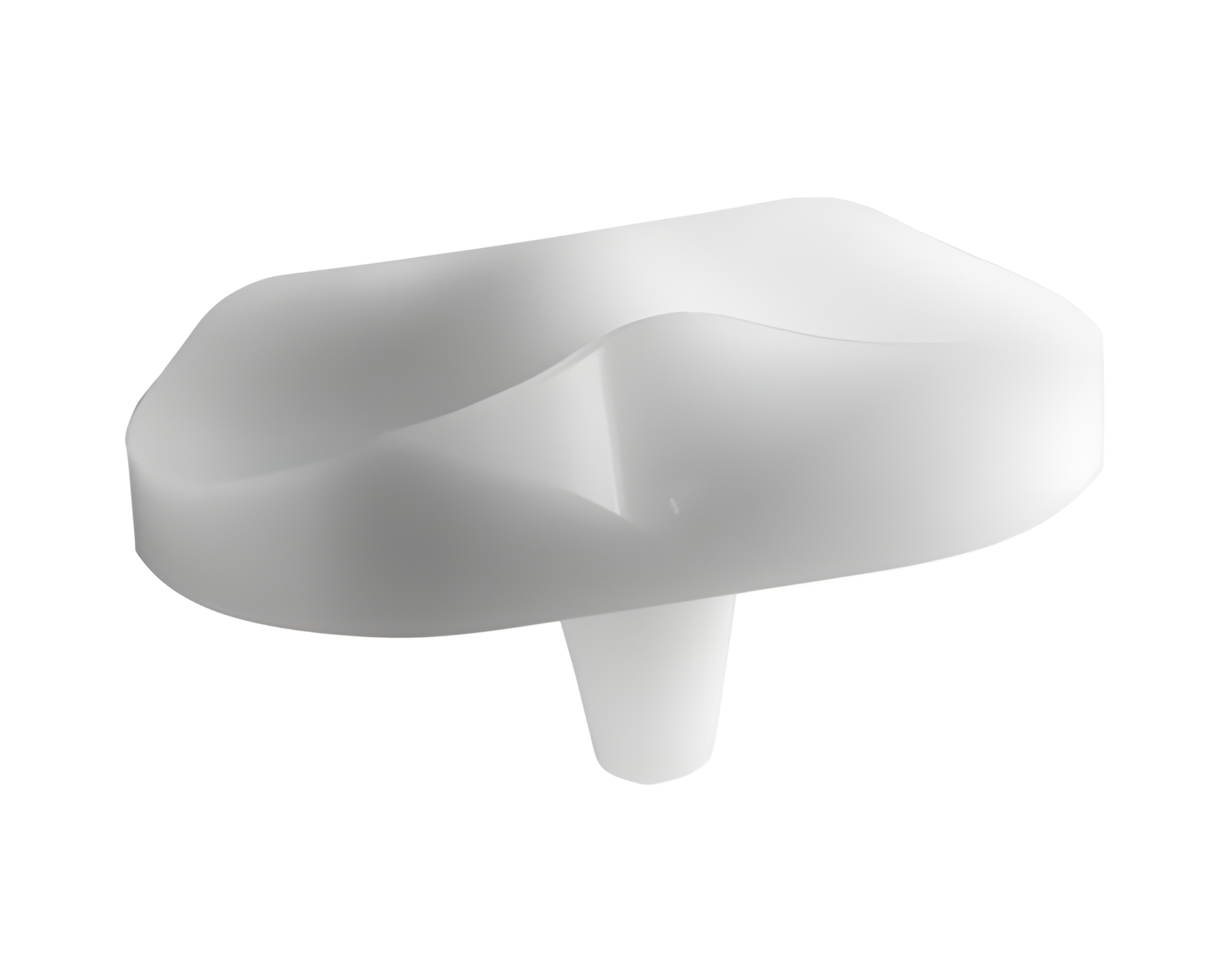

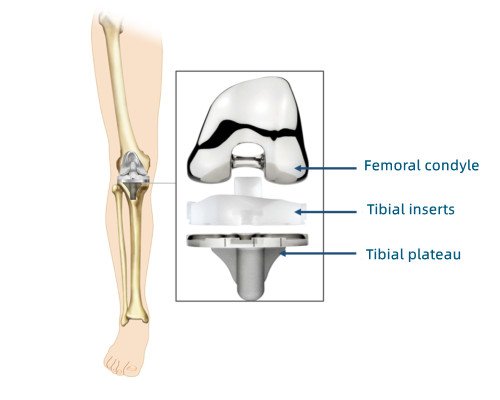

Polyethylene bone pads are orthopedic implants made of high-density polyethylene (HDPE) or ultra-high molecular weight polyethylene (UHMW-PE), which have excellent wear resistance, low friction coefficient and excellent biocompatibility. This material exhibits strong chemical corrosion resistance and low water absorption in the human body, which can effectively reduce wear and inflammatory response in joint replacement and extend the service life of implants. Polyethylene bone pads are widely used in artificial joint replacement surgeries such as hip joints, knee joints and shoulder joints, and are an indispensable key material in the field of modern orthopedics.

Unrivaled Sharpness:The single-crystal diamond edge ensures minimal cutting forces, reducing deformation and achieving precise cuts with mirror-like finishes.

Outstanding Wear Resistance:The inherent hardness of monocrystalline diamond enables extended tool life, even in continuous operations.

Low Adhesion:MCD tools significantly minimize material adhesion and chip buildup, ensuring a clean and smooth machining process.

Optimized for Soft Materials:Specifically engineered for UHMWPE, these tools maintain high performance without compromising the structural integrity of the workpiece.

Superior Heat Management:Reduced friction at the cutting interface lowers thermal buildup, preventing material softening and enhancing

Precision machining of polyethylene tibial inserts for artificial knee joints.

High-tolerance operations in medical device manufacturing.

Achieving superior surface finishes for biocompatible components.

| Precision MCD diamond end mill Tools | Diamond materials | CVD diamond |

| HPHT diamond | ||

| Maximum Diameter | 0.05mm | |

| Minimun Diameter | 5mm | |

| Effective use angle | 90° | |

| Angle | 30° | |

| Rear angle | 0° | |

| Back angle | 15° | |

| Waviness | 2μm-30nm | |

| Bracket | Solid handle | |

| Handle | Tunsten carbide | |

| Molybdenum | ||

| Steel | ||

| Handle shape | Round | |

| Minimum length | 3mm | |

| Support customization according to drawings | ||

Enhanced Efficiency: Reduced tool changes and extended tool life minimize downtime and operational costs.

Improved Surface Quality: Achieves the high-gloss, burr-free surfaces required for medical-grade components.

Consistent Performance: Designed to meet the rigorous demands of the medical industry, ensuring reliable results every time.

We offer tailored solutions to meet your unique machining requirements, including custom geometries, special shank designs, and specific tool sizes.

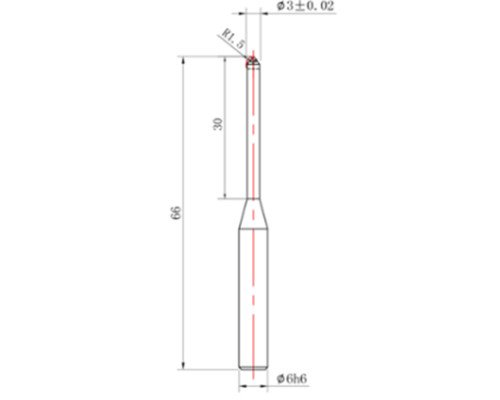

| Workpieces | Total Knee Polyethelen Prosthesis Insert |

| Diameter | 4mm |

| Holder Diameter | 6mm/8mm |

| Tools type | Spherical end mills |

| Tools materials | CVD diamond |

| Cutting depth | 30mm |

| Maximun Roughness | Ra20μm |

| Test Results | High processing efficiency, surface finish meets customer requirements, helping customers reduce costs |