what is diamond band saw blades?

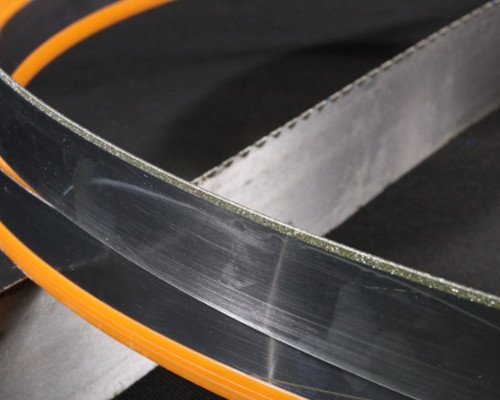

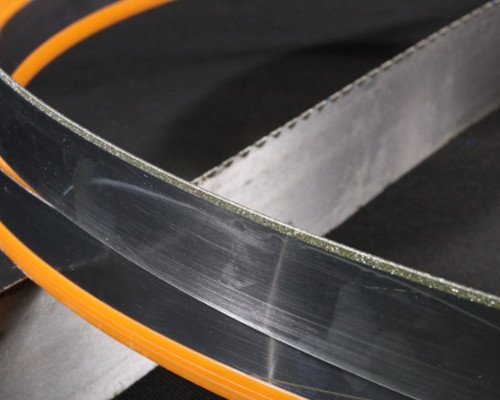

Diamond band saws are composed of diamond particles and a metal base. As the main part of cutting, diamond particles have extremely high hardness and wear resistance, and can remain sharp during the cutting process. The metal base provides support and stability, ensuring the overall structure of the band saw is solid.

Applications of diamond band saws

Diamond band saw blades remain the tool of choice for many diamond cutting and machining operations. The perfect solution for cutting a wide range of ultra-manual and brittle materials such as: quartz, glass, carbon, silicon, ceramics or composites

Features of diamond band saw blades for silicon ingot

By using a high-strength substrate to achieve a thin blade, silicon loss during cutting can be reduced. Through special tension processing of the substrate, the vertical cutting performance remains stable. High-efficiency, high-precision cutting is achieved by using lattice plating that corresponds to cutting conditions.

| Length(mm) | Width(mm) | Thickness(mm) | |

| 3230 | 40 | 0.7 | |

| 3440 | 40 | 0.7 | |

| 3530 | 40 | 0.7 | |

| 3700 | 80 | 0.6 0.7 | |

| 4320 | 60 | 0.5 0.6 0.7 | |

| 5400 | 60 | 0.5 0.6 0.7 | |

| 6095 | 40 | 0.7 | |

| other specifications can be made according to customers requirements | |||

|

Continuous

A variety of band core width available Continuous rim design reduces the saw marks on the materials Suitable for dry cutting hard materials , such as glass , ceramic , carbon materials and so on. |

|

segmented ( half moon):

Cutting hard and brittle materials Superior tool life and cutting ability in silicon processing Allows greater flexibility in customizing blade edge width and pitch |

|

Serrated :Wide width band saw blades possible

Cutting difficult to cut materials Reduced -loading saw tooth design encourages chip evacuation |