Grinding natural diamond waistline grinding wheel

Vitrified diamond bruting wheel is suitable for grinding and polishing of natural diamonds. It can replace polycrystalline diamonds, and the effect of processing diamonds is very good.

Diamond grinding tools are installed on advanced CNC grinding tools, which are widely used in polishing abrasive tools for natural diamonds, precious stones, and agate. It can replace PCD (polycrystalline diamond) and has excellent diamond processing performance. Diamond bruting wheels are widely popularized in countries with the most developed diamond industries such as South Africa, Hong Kong, India, Belgium, Namibia, Israel, etc., proving its advantages in the jewelry processing industry.

Vitrified diamond bruting wheel advantages

1.good sharpness

2.high grinding efficiency

3.good self-sharpening

4.high surface finish and not easy to clog during grinding

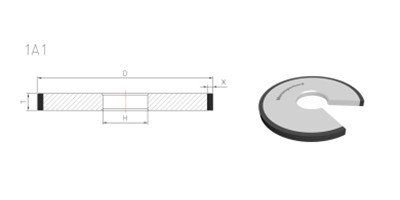

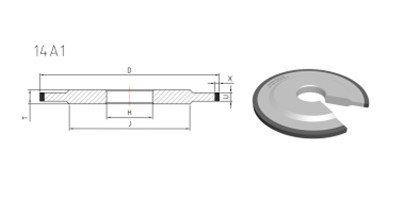

Diamond bruting wheel details and drawing

| Model | D(mm) | T(mm) | H(mm) | X(mm) | U(mm) |

|

80 | 10 | 32 | 8,10 | |

| 150 | 10 | 32 | 10 | ||

| 155 | 10 | 32 | 10 | ||

| 160 | 10 | 32 | 10,12 | ||

| 170 | 10 | 32 | 10,12,14 | ||

| 175 | 10 | 32 | 10 | ||

| 220 | 10 | 32 | 20 | ||

|

170 | 10 | 32 | 10,12,14 | 5 |

| 175 | 10 | 32 | 10,15 | 5 |

How to choose suitable grian sizes of diamond bruting wheel

Grain sizes: MD20, MD40, MD60, MD80

MD-20: fine polishing, perfect luster, long service life of polished small diamonds (10 points – 1k)

MD-40, MD-60: Large diamond rough polishing, efficient polishing, sharp cutting. (1ct, 1.2ct and 1.3 carats, etc.)

MD-80: Coarser polish for greater efficiency and sharper cutting of larger stones. (2 carats, 3 carats, etc.)