Rollers are important parts of rolling mills. They use the pressure generated by a pair or a group of rolls to roll steel. They are mainly subject to the dynamic and static loads, wear and temperature changes during the rolling process. As the most important vulnerable part of the rolling mill, the production process of rolls is complex.

The materials used to manufacture rolls need to have the characteristics of high strength, high wear resistance, good corrosion resistance and fatigue resistance. Commonly used roll materials include forged steel, cast steel, hardened steel, high-speed steel, alloy steel, cast iron, cemented carbide, ceramics, rubber and synthetic materials.

| Roller materials | Diamond abrasives | CBN abrasives |

| Carbide,ceramic,cast iron,rubbe and composite materials etc | All steel materials like cast steel, hardened steel etc |

| Diameter (mm) | Diameter (inch) | H (mm) | T (mm) | X (mm) |

| 25 | 1 inch | 6 | 12 | 6 |

| 30 | – | 12 | 6 | – |

| 40 | – | 12 | 6 | – |

| 50 | 2 inch | 6 | 12 | 6 |

| 100 | 4 inch | 12 | 12 | 10 |

| 150 | 6 inch | 12 | 25 | 10 |

| 300 | 12 inch | – | 25 | 10 |

| 400 | 16 inch | 127 | 25, 50 | 10, 25 |

| 500 | 20 inch | 127, 203.2 | 25, 50 | 10, 25 |

| 600 | 24 inch | 254 | 25, 50 | 10, 16, 25 |

| 750 | 30 inch | 304.8 | 50 | 10 |

| 914.4 | 36 inch | 304.8 | 25, 50 | 10, 25 |

| 1100 | 43 inch | 304.8 | 50 | 10 |

We offer custom grinding wheels according to your requirements.

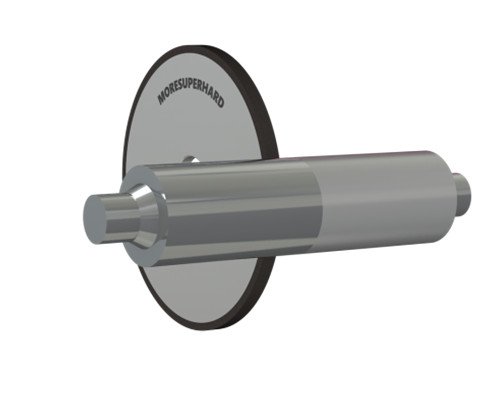

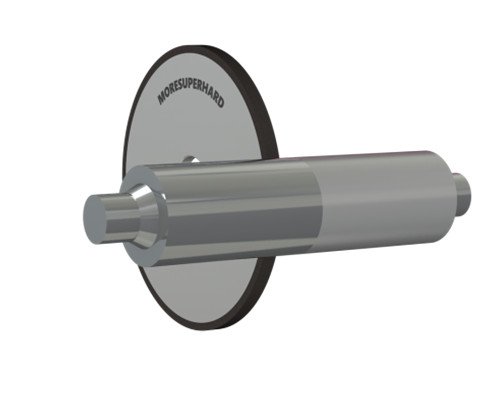

| Application | Cylindrical external grinding

|

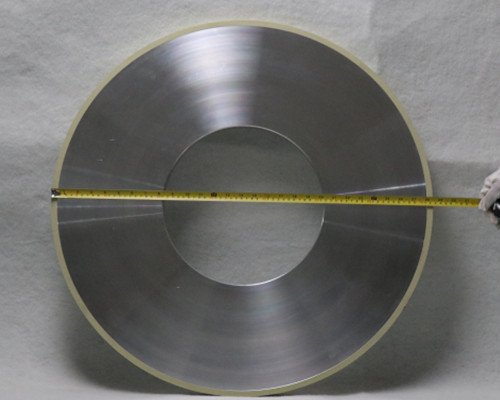

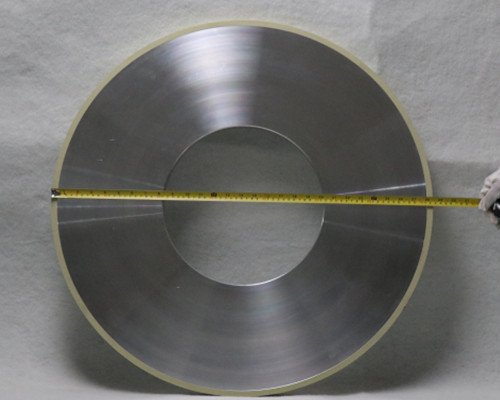

| Wheel sizes | 1A1 D750-70T-10X-3R-304.8

|

| Specification CBN wheel used | CBN 107

|

| Machine | HERKULES |

| Workpieces specifications | Ø550 x 2500mm

|

| Workpieces Material | Hardened steel

|

| Hardness | 62HRC

|

| Coolant | Emulsion |

| Stock removal | 0.2mm |

| Roughness achieved | Ra0.8 |

| Results | Time process reduced about 50% compared with Conventional grinding wheel |