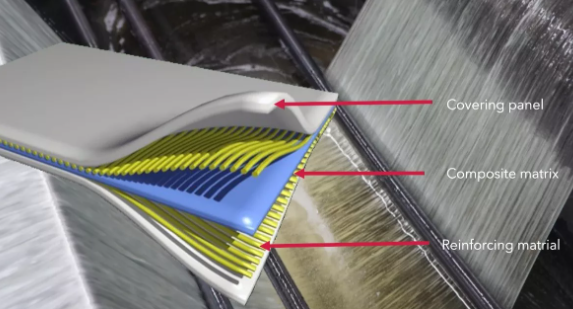

Composites processing is fundamentally different from metal processing. In metal processing, the machined material is softer than the cutting tools, and the machined material will form continuous, serrated intermittent chip deformation during the cutting process. The processing of composite materials is itself a series of brittle destruction processes, in which the impact of the cutting edge causes the hard fiber to shatter, forming a powder or brush-like debris.

Composite materials are typical difficult to process materials, easy to tear, burr, delamination, thermal damage and other processing problems, the sharpness, wear resistance and stability of the cutting tools put forward extremely high requirements. For processing composite materials, the tool is usually cut with diamond coating tools or PCD tool.

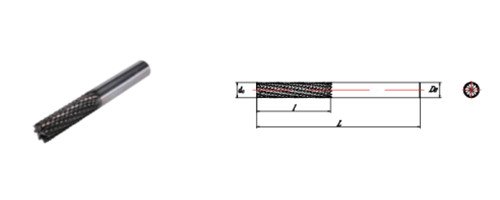

The optimized carbide matrix makes the hardness of the tool matrix high.

Submicron WC particles, which can achieve high wear resistance;

Left/right cross edge design, in order to improve the sharpness of the tool, effectively reduce the lamination and burr generation;

Strong close tooth design, improve processing efficiency and accuracy;

Adopt sharp positive front angle design, reduce chip force and cutting heat, avoid defects such as tear and burr of composite material;

Nano-diamond coating, slow tool wear, tool life doubled.

| dc/mm | l/mm | L/mm | Ds/mm | Z | End tooth type | Coating Type |

| 4 | 12 | 62 | 4 | 6 | No/End Mill/Drills | No/Diamond Coated |

| 6 | 18 | 62 | 6 | 8 | No/End Mill/Drills | No/Diamond Coated |

| 6.35 | 18 | 62 | 6.35 | 8 | No/End Mill/Drills | No/Diamond Coated |

| 8 | 25 | 78 | 8 | 8 | No/End Mill/Drills | No/Diamond Coated |

| 9.525 | 25 | 78 | 9.525 | 10 | No/End Mill/Drills | No/Diamond Coated |

| 10 | 25 | 78 | 10 | 10 | No/End Mill/Drills | No/Diamond Coated |

| 12 | 25 | 78 | 12 | 12 | No/End Mill/Drills | No/Diamond Coated |

| 12.7 | 25 | 78 | 12.7 | 12 | No/End Mill/Drills | No/Diamond Coated |

| Workpiece material | CFRP composite (T700, T800 grade) |

| Machine | Vertical machining center |

| Shank | HSK63A heat shrink shank |

| Cutting method | dry cutting |

| Tool specification model | D8*25*L78*SD8*Z8 |

| Coating | diamond coating |

| Cutting speed | Vc=200m/min |

| Feed | F=800mm/min |

| Cutting width | ae=8mm |

| Cutting depth | ap=5mm |

| Processing result | The processing length is 30m, the surface of the composite has no burr, tear and other defects, and the surface finish is less than Ra1.6. |