Applications of diamond cup grinding wheels

Diamond grinding wheels are used for grinding PCD cutting tools, PCBN cutting tools, CVD tools, MCD tools, milling cutter, reamer, drill and regrinding. Diamond cup grinding wheel also is used for grinding PCD and PCBN tools, glass, ceramics, quarts, semi-conductors, and other non-metallic materials.

* When grinding CBN tools, resin bond diamond grinding wheel is mostly used. If the machining tolerance is big, you can use 140/170 for rough grinding,then use230/270,W35,W28 for fine grinding. If you want to save cost & time you can choose W35 for whole grinding.

PCD and CBN cutting tools are widely used in metal cutting and processing nowadays.”More Super Hard Products” devotes to offer an efficiency and economic solution in PCD and CBN cutting tools grinding

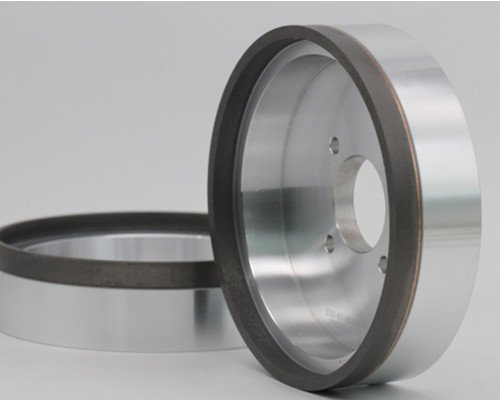

Advantages of diamond cup grinding wheel

– Precision control of geometric tolerance

– Good self-sharpening

– High working efficiency

– Good elastic, good polishing performance

– Superior insert edge quality

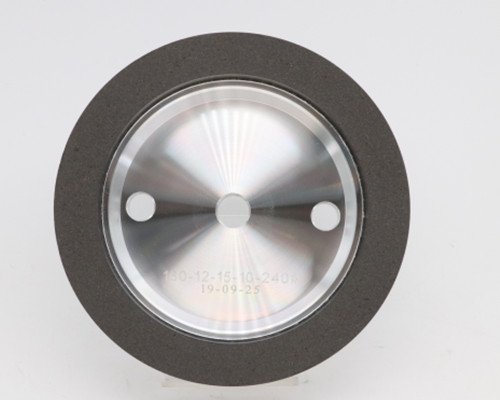

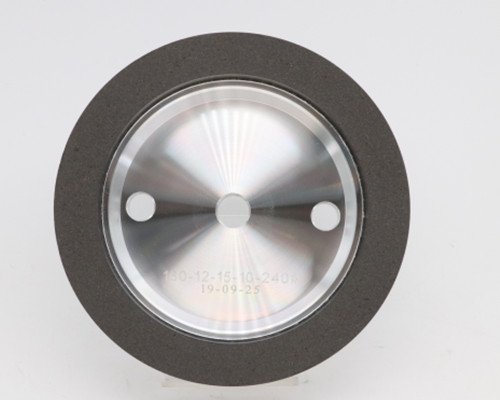

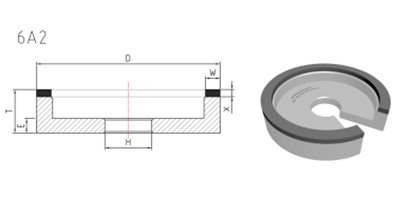

The specification of diamond cup grinding wheel

| Model | D(mm) | T (mm) | H (mm) | W (mm) | X (mm) |

| 6A2 | 150 | 40 | 32 40 | 3 5 10 15 20 | 10 |

| 125 | 40 | 32 40 | 3 5 10 | 10 | |

| 100 | 40 | 32 40 | 3 5 10 20 | 10 | |

| Grit: 325/400, W40 (500#), W28 (600#), W20 (800#), W10 (1500#), W5 (3000#), W3 (5000#) | |||||

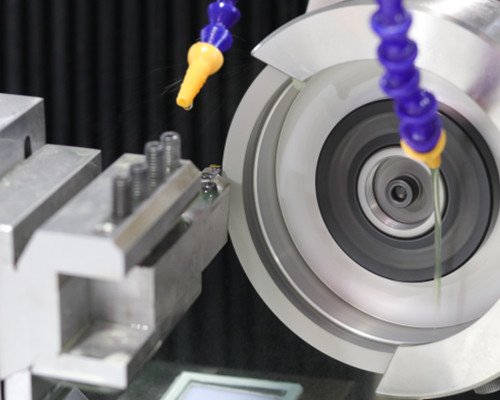

Suitable PCD Grinding Machines: Coborn, Ewag, Anca, Farman, Mytech

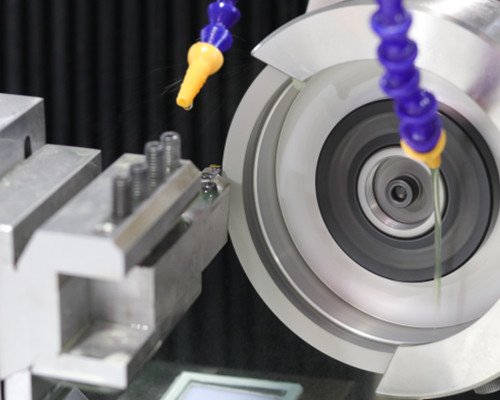

| Grinding machine | EWAG EasyGrind |

| Coolant | Emulsion |

| Workpiece | PCD insert (brazed, include carbide ) |

| Grinding Parameters | |

| Feed Rate | Vf = 2mm/min |

| Stock | 0.3mm |

| Cutting Speed | Vc=15m/s |

| Advantage | |

| 1, 35%-time savings 2, 20% working life time increase 3, Chipping < 10μm |

|