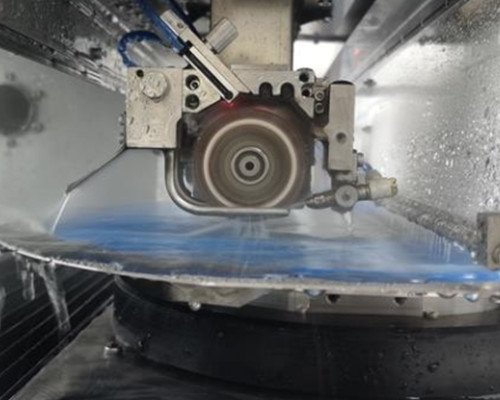

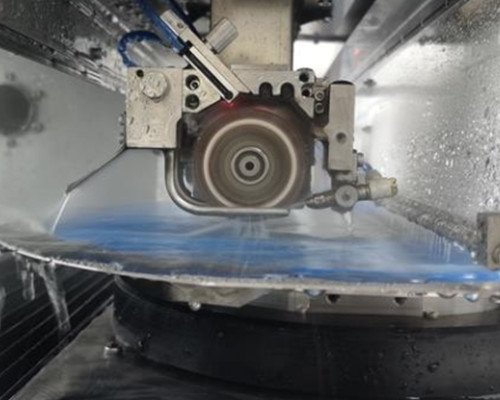

1.High-Efficiency Cutting: The hub-type dicing blade employs advanced cutting technology, enabling fast and efficient cutting processes, thereby improving production efficiency.

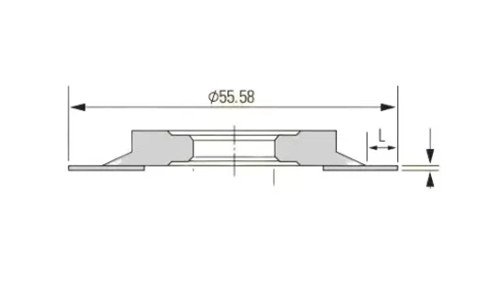

2.Precise Positioning: With precision-designed hubs and blade structures, it achieves accurate positioning and cutting of wafers, ensuring cutting accuracy and consistency.

3.High Stability: Manufactured using high-quality materials, the tool boasts a stable structure and long service life, maintaining stable performance during prolonged production operations.

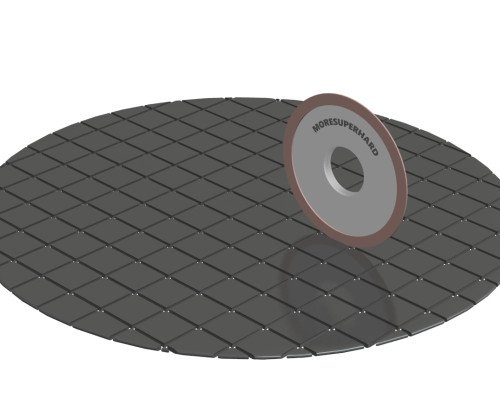

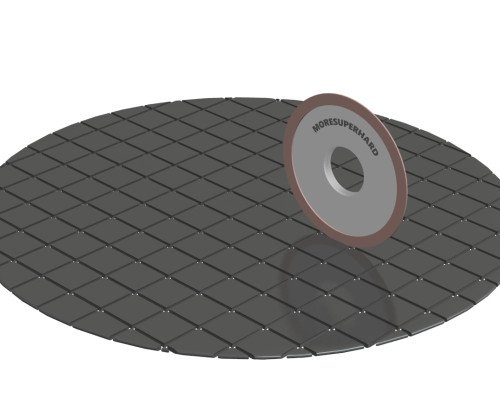

4..Wide Applicability: The hub-type dicing blade is suitable for various types of wafer materials, including silicon, silicon carbide, gallium nitride, etc., with a wide range of application areas.

5.Ease of Operation: Featuring a user-friendly interface and control system, it is easy to operate, reducing the technical requirements for operators.

Applications of electroformed hub blades

1.Semiconductor Industry: Used for cutting and processing semiconductor chips.

2.Optoelectronics Industry: Applied in the cutting and processing of optoelectronic devices.

3.Microelectronics Industry: Utilized for cutting and processing microelectronic components.

4.Other Fields: Suitable for various industries requiring precise cutting of hard and brittle materials.

| Exposure(μm) | 380 | 510 | 640 | 760 | 890 | 1020 | 1150 | 1270 | Grit Size |

| Kerf width(μm) | 380-510 | 510-640 | 640-760 | 760-890 | 890-1020 | 1020-1150 | 1150-1270 | 1270-1400 | #5000 #4800 #4500 #4000 #3500 #3000 #2500 #2000 #1800 #1700 #1500 |

| 16-20 | 20*380 | 20*510 | |||||||

| 21-25 | 25*380 | 25*510 | 25*640 | ||||||

| 26-30 | 30*380 | 30*510 | 30*640 | 30*760 | 30*890 | 20*1020 | |||

| 31-35 | 35*380 | 35*510 | 35*640 | 35*760 | 35*890 | 35*1020 | |||

| 36-40 | 40*380 | 40*510 | 40*640 | 40*760 | 40*890 | 40*1020 | 40*1150 | ||

| 41-50 | 50*380 | 50*510 | 50*640 | 50*760 | 50*890 | 50*1020 | 50*1150 | ||

| 51-60 | 60*510 | 60*640 | 60*760 | 60*890 | 60*1020 | 60*1150 | 60*1270 | ||

| 61-70 | 70*640 | 70*760 | 70*890 | 70*1020 | 70*1150 | 70*1270 | |||

| 71-80 | 80*890 | 80*1020 | 80*1150 | 80*1270 | |||||

| 81-90 | 90*1020 | 90*1150 | 90*1270 | ||||||

| Special size can be designed according to customers’ requirement | |||||||||