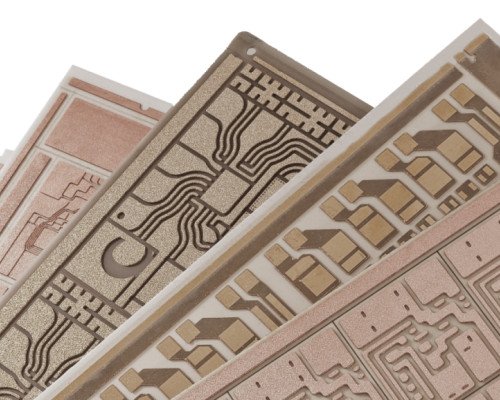

Ceramic substrate is a sheet material based on electronic ceramics that forms a supporting base for circuit components. It is the most popular packaging material for the new generation of communication and new energy automotive electronic devices, and is the preferred material for achieving high-density integrated heat dissipation.As a substrate material with excellent performance, ceramic substrates are widely used in electronic packaging, power devices, high-temperature electronic devices and other fields.

Metal bond diamond dicing blades: Metal bond has strong ability to hold diamond abrasive, high wear resistance, good shape retention and long service life.

Resin bond diamond dicing blades:Resin bond diamond scriber: good self-sharpening, sharp cutting, elastic bond, can improve the dicing surface quality.

1. MORESUPERHARD’s dicing blade has good elasticity, which can maximize the cutting ability;

2. High precision, sharp cutting, good self-sharpening, fast particle renewal, effectively ensuring the good cutting state of the blade;

3. Different blades can be customized and designed according to different processing materials, and the blade can also be slotted to meet different processing needs.

4. The blade can be adapted to the mainstream dicing machine in the market and is an important tool for cutting ceramic packages.

The selected diamond abrasive is used to make the blades have excellent dicing performance and long service life.

Advanced manufacturing technology is adopted to control the concentration of diamond abrasive and the bond, which effectively reduces the probability of material edge collapse during dicing.