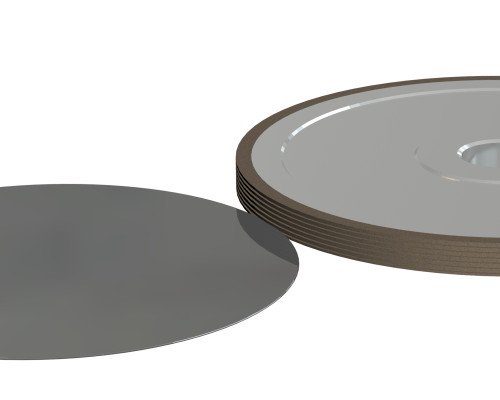

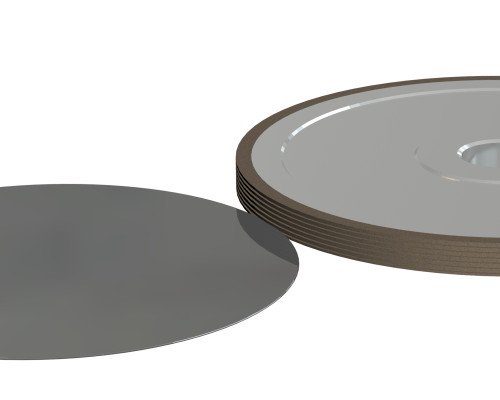

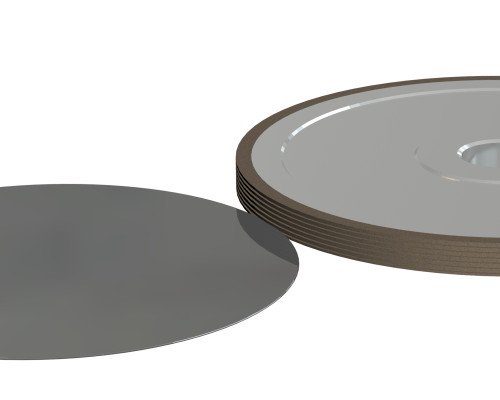

Diamond edge grinding wheel for semiconductor wafers

Suitable for 2”-12” silicon wafer,SiC wafer,GaAs sapphire etc.

Why semiconductor wafers need to be chamfered?

Taking silicon wafers as an example, chamfering the silicon wafer can obtain a smooth radius contour on the edge of the silicon wafer. This step is usually performed before or after grinding. Cracks and small cracks at the edges of the wafer can create mechanical stresses on the wafer and can generate dislocations, especially during the high temperature processes of wafer preparation. Small cracks can become a trap for harmful contaminants and cause particle shedding during the production process. Smooth edge radii can minimize these effects. According to different needs, chamfering is divided into T-type chamfering (large chamfering) and R-type chamfering (small chamfering).

(1) Prevent wafer edge chipping

(2) Prevent the concentration of thermal stress

(3) Increase the flatness of the epitaxial layer and photoresist layer at the edge of the wafer

| D (mm) | T | Grit | bonded | Groove |

| 50 – 250 | 3 – 20 | 325 – 3000# | Metal / resin | 1-10G |

| Other size can be designed according to customers’ requirement | ||||

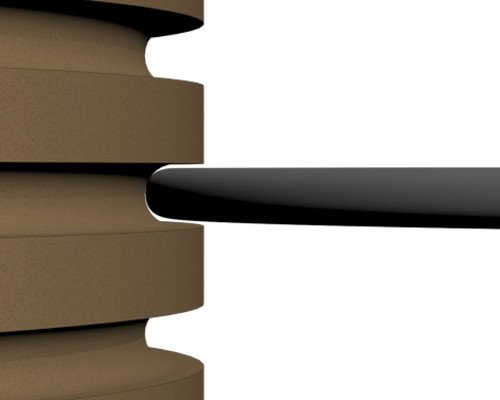

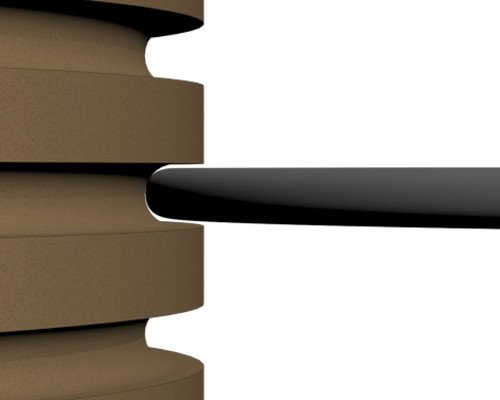

Feature of Moresuperhard hard diamond edge grinding whee

– Grinded with uniform chamfer width, excellent rigidity

– Strong groove shape retention, long life

– By edge grinding the final diameter is adjusted

– A uniform diamond layer minimizes machining damage

– Highly precise slotted shape support various wafer shapes