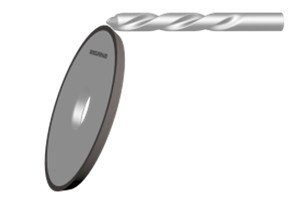

Moresuperhard company is always focus on providing cnc cutting tools grinding solutions.Recent years,Moresuerhard continuously improve the formula, develop and produce diamond grinding wheels for fluting of cermet rotary tools .Moresuperhard diamond fluting grinding wheels are widely used in cnc cermet rotary cutter machining.

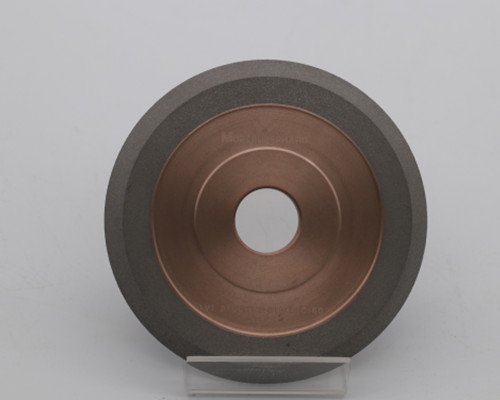

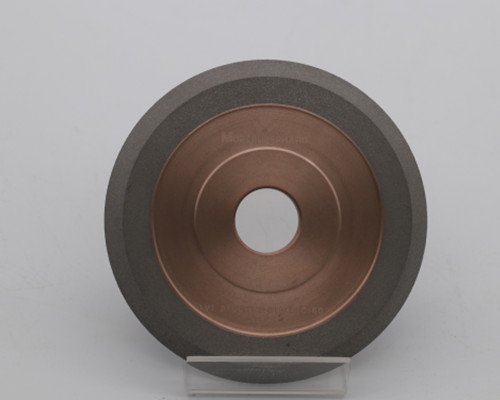

Diamond grinding wheel for Fluting

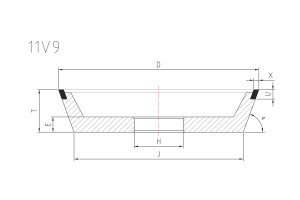

Diamond grinding wheel for edge cleaning

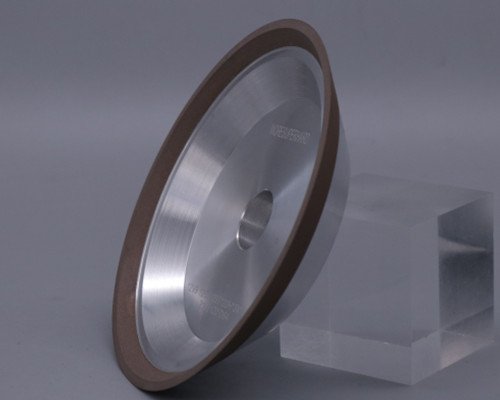

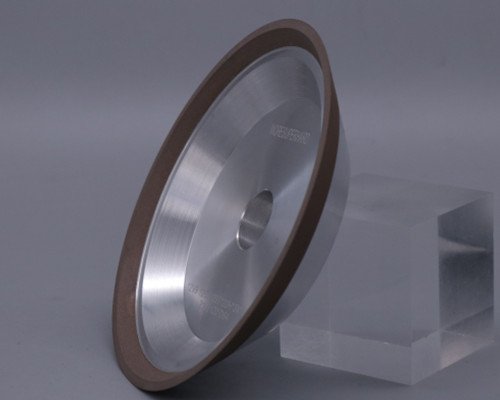

Diamond grinding wheel for tooth grinding

Products characteristics

1.High chip rate, low grinding resistance, low grinding temperature

2.Large depth of cut, fast feed, high processing efficiency

3.Excellent shape retention Micro-vibration, low load, no damage to machine tool spindle

4.perfect edge quality

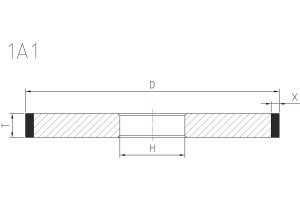

Specifications and drawing of diamond fluting wheel for cermet cutter

| D(mm) | T(mm) | X(mm) | H(mm) | Grit |

| 75 | 10 | 5 | 20 | D64 |

| 100 | 6,10,12 | 5,10 | 20 | D46,D64 |

| 125 | 10,12,16 | 10 | 20 | D46,D64 |

| 150 | 12 | 10 | 20 | D64 |

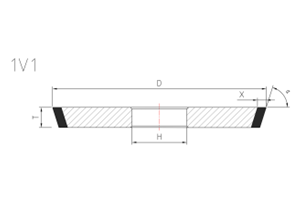

| D(mm) | T(mm) | X(mm) | H(mm) | V° |

| 75 | 10 | 5 | 20 | 45 |

| 100 | 15 | 5 | 20 | 45 |

| 125 | 6,10,15 | 5 | 20 | 45 |

| 150 | 12 | 5 | 20 | 45 |

| D(mm) | T(mm) | X(mm) | H(mm) |

| 75 | 3 | 10 | 20 |

| 100 | 2,3 | 10 | 20 |

| 125 | 3 | 10 | 20 |

CNC Grinder:Walter、Anca、Saacke、Rollomatic,Schutte, Schneeberger, Makino, TG-5, Studer, Strausak, Cincinnati, Griffo, Huffman,Jungner.

Grinding experiment of Cermet end mills with diamond fluting wheel

Workpiece:6mm four-edged cermet knife, blade length 16mm

Diamond grinding wheel: Moresuperhard metal diamond strong fluting wheel, outer diameter 100mm, thickness 5mm, grain size D35.

Raw material: φ6 cermet bar of a well-known cutting tool in China.

Grinding machine: Beiping BPX5 CNC grinding machine.

Grinding paraments: 2 or 4 blades spiral flute, flute length 15mm, angle 45/35 degrees, line speed 23m/s, feed 20‐100mm/min, single depth of cut 0.9‐2.0mm, a total of 11 pieces were processed.

Detection equipment: Keyence VHX‐6000, magnified 200 times for detection.

Grinding results:

1. On the premise of meeting the quality requirements of the cutting edge, the depth of cut is 1.05mm according to the standard 6mm tool, and the maximum feed rate can reach 80mm/min.

2. The maximum cutting depth can reach 1.5mm. At this time, the maximum corresponding feed rate is about 50mm/min, and the processing time of a single four-edged tool is about 150s.

3. After processing, the shape retention of the grinding wheel is good, the R angle increases from 0.1mm reserved during dressing to about 0.15mm, the outer diameter of the grinding wheel decreases by about 0.038mm, and there is no obvious clogging phenomenon.