Ceramic bonding tools are prone to chipping and burning during grinding due to their high hardness and low toughness. Moresuperhard grinding wheels have excellent heat dissipation performance and sharp cutting ability, which can effectively reduce grinding heat accumulation, reduce the risk of workpiece burns, and improve the service life and processing accuracy of the tool.

Moresuperhard provide a variety of specifications and formulas to meet different types of ceramic tool processing needs. At the same time, we can customize the grinding wheel specifications according to customer requirements to meet special application scenarios.

High precision: ensure the smoothness and dimensional stability of the grinding surface, and reduce the subsequent processing steps

High wear resistance: use high-quality abrasives, longer service life, and reduce the frequency of replacement

Good heat dissipation: reduce heat accumulation, reduce the risk of workpiece burns, and improve processing stability

Low vibration: optimize balance, reduce vibration, ensure processing accuracy and improve efficiency

Wide range of application: suitable for ceramic materials such as zirconium oxide, aluminum oxide, silicon nitride

Customizable: provide different specifications, particle sizes and binder formulas to meet personalized needs

| Specifications | |

| Diameter(D) | 50mm/75mm//100mm / 125mm / 150mm / 200mm |

| Thickness(T) | 1mm / 2mm / 5mm / 10mm |

| Hole(H) | 20mm / 25.4mm / 32mm |

| Grit | 500#-3000# |

| Bond | Resin bond/metal bond |

| Applied Materials | Alumina ceramics / Silicon nitride ceramics / Silicon carbide ceramics |

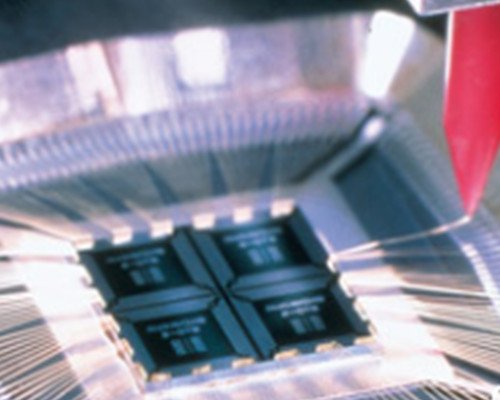

| Application Areas | Electronic ceramics, semiconductors, precision tools, aerospace |

If you have special requirements, please provide detailed information and we can customize the appropriate grinding wheel specifications!

1.Suitable grinding wheel and grit sizes

Resin-bonded diamond wheels and metal-bonded diamond wheels are suitable for grinding ceramic chip bonding tools. Choose the appropriate diamond wheel grit according to the different grinding stages:

Rough grinding: Use a coarse-grained diamond wheel of D46 or D76 for preliminary removal of excess material.

Semi-fine grinding: Use a medium-grained diamond wheel of D20 or D30 to further refine the tool shape.

Fine grinding and polishing: Use a fine-grained diamond wheel of D7 or D10 to ensure surface finish and accuracy.

2.Determine grinding parameters

Reasonable grinding parameters (such as grinding speed, feed speed, grinding depth, etc.) have a significant impact on the final processing quality. The recommended parameters are as follows:

Grinding speed: According to the material hardness and grinding wheel characteristics, it is usually controlled at 20-30 m/s.

Feed speed: Keep it at 0.01-0.1 mm/s to avoid excessive feed speed causing tool breakage.

Grinding depth: Each grinding depth should be less than 0.02 mm, and the grinding depth should be reduced during the fine grinding stage to ensure surface quality.