Diamond Rotary Tools

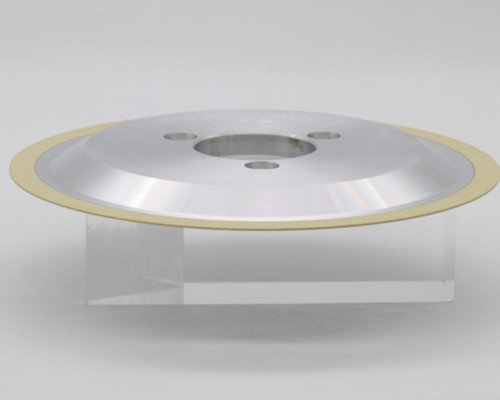

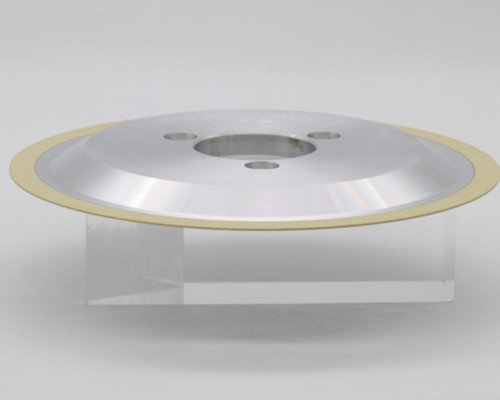

The diamond roller is a high-efficiency, long-life, low-cost grinding wheel dressing tool for special machine tools and gear grinding machines for mass profile grinding.

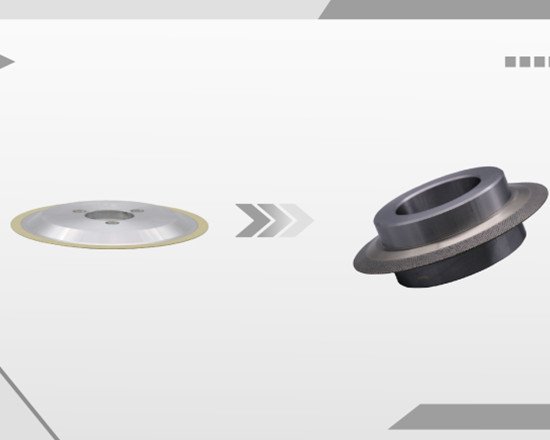

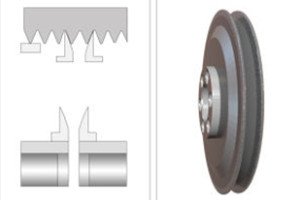

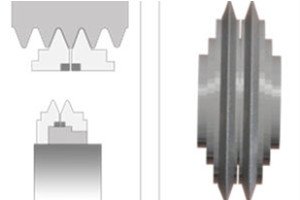

Working principle of the diamond roller

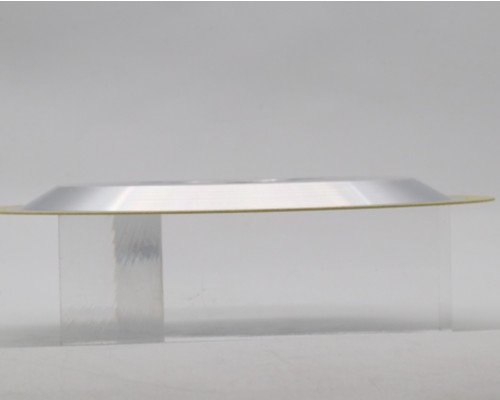

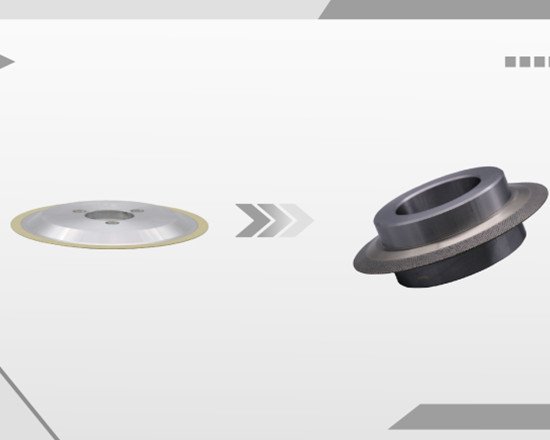

The working principle of the diamond roller is: by being installed on the dressing device of the grinding machine, the diamond roller dresses the ordinary ceramic grinding wheel or CBN grinding wheel. Grinding the parts after the grinding wheel is formed, so that the contour, precision and size of the diamond roller are copied to the surface of the processed part through the grinding wheel.

Used for high-precision electroplated diamond/CBN grinding wheel, electroplated diamond roller, etc.

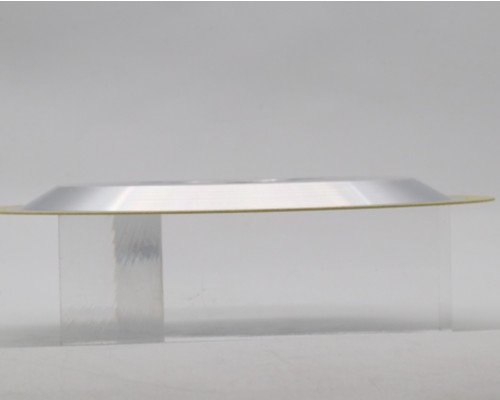

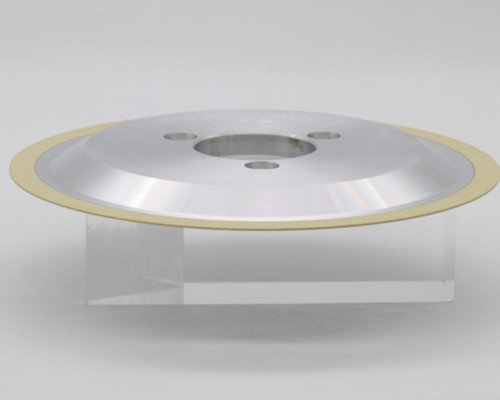

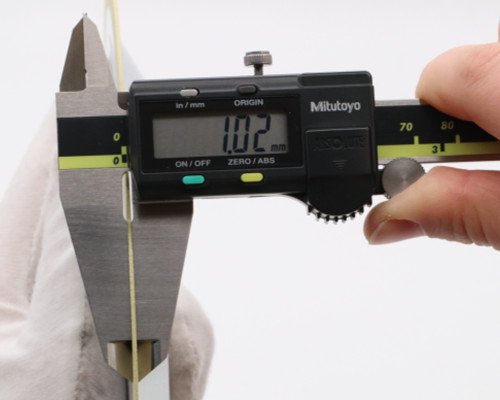

Moresuperhard provides customized ceramic optical profile grinding wheels for dressing high-precision diamond rollers. Electroplated/sintered diamond rotary dresser need to undergo repeated grinding and testing on the grinding machine during the production process to maintain the corresponding size and precision. The vitrified diamond grinding wheel has the advantages of less wear and tear when dressing high-precision rollers, maintaining good shape accuracy, ensuring small linearity errors of the profile generatrix, reducing grinding burns, reducing surface roughness, and prolonging the service life of the rollers.

Application fields of vitrified diamond optical profile grinding wheel

Vitrified diamond optical profile grinding wheel is used for grinding and dressing of high-precision electroplated diamond/CBN grinding wheels, electroplated diamond rollers, diamond sintered rollers, PCD/CBN/MCD tools, diamond grinding wheels, wear-resistant parts and various diamond tools.

Supporting special grinding machines: WAIDA, WASINO, PROFILTEC, PETEWE, DOEBLI, etc.

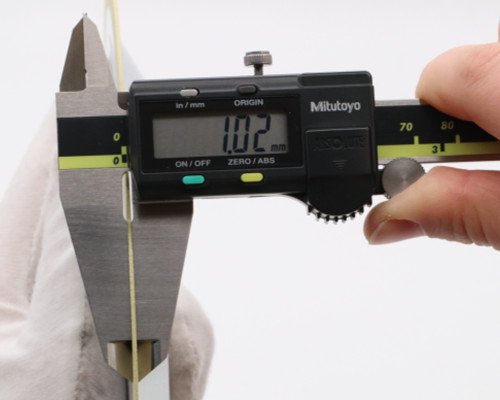

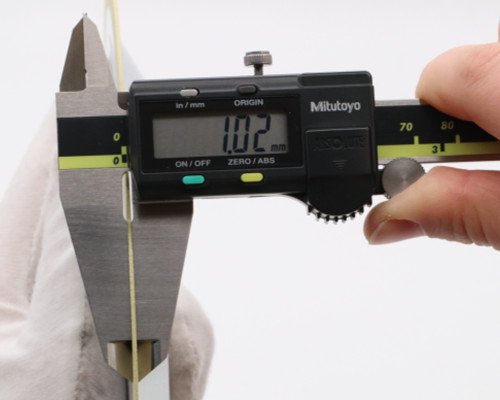

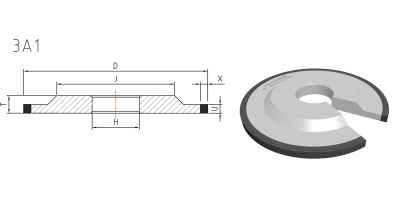

Specification of optical profile grinding wheel

| Model | D(mm) | H(mm) | T | U | X | Grit |

| 3A1 | 125

150 200 |

22

31.75 |

10 | 1

1.2 1.5 2 |

5

10 |

#200~ |

| Other specifications and sizes can be customized according to drawings | ||||||