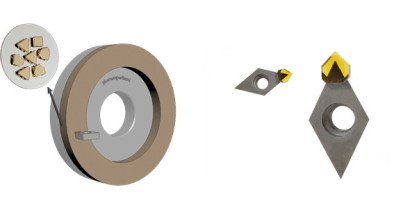

Single crystal diamond SCD tool has become the main cutting tool in the field of ultra-precision machining. Compared with PCD tool, single crystal diamond tools can better realize mirror processing, processed workpiece with high precision and surface roughness, and long service life. So single crystal diamond tool is widely used in the field of ultra-precision processing. It is very important to solve the problem that the cutting edge of single crystal diamond tool is prone to crack and serration.

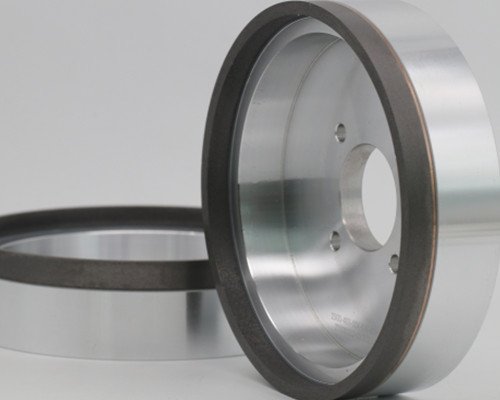

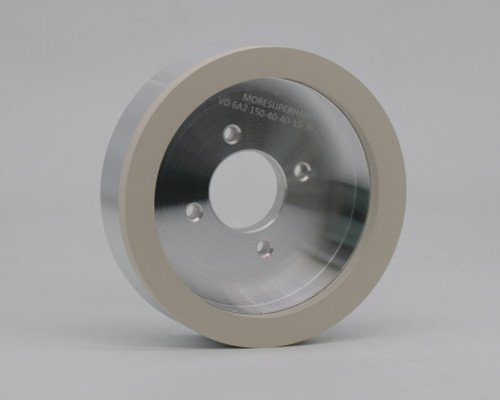

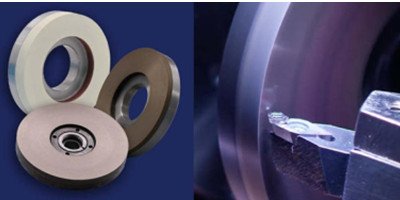

Vitrified bond, Metal bond diamond wheel for PCD tool grinding machine

– Moresuperhard rough grinding wheel has successfully matched Coborn RG5 and RG9A, EWAG-RS15,FC-200D, MT-188,MT198NC, and other domestic brands diamond PCD tool grinder.

– Grit size range from rough grinding W40 – fine grinding W1.5(10000#).

Single crystal diamond tool sharpening method

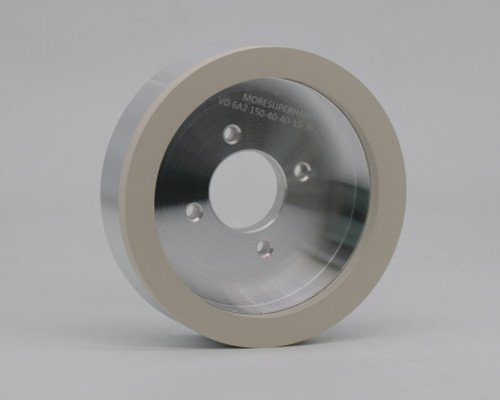

Diamond wheel for Corborn PG series grinder

1A2 Vitrified bond and Metal diamond wheel sucessfully matched Coborn PG3 grinder for Single Crystal Diamond tool

Metal bond, Vitrified bond diamond wheels are used for mono crystal diamond (MCD) or synthetic single crystal diamond (SCD), manufactured by either high pressure high temperature (HPHT) or chemical vapour deposition (CVD). Metal bond diamond wheel can used for single crystal diamond tool manufacture with ultra-high precision.

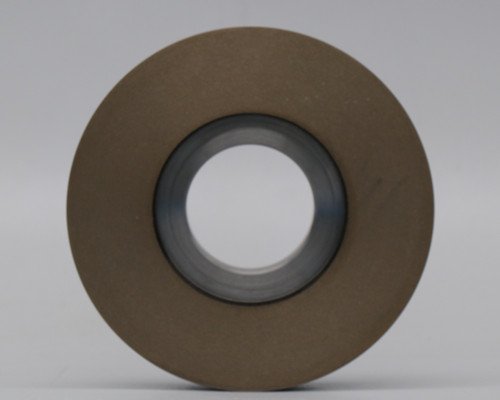

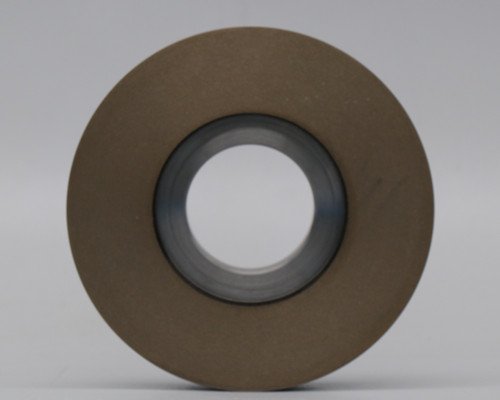

vitrified bond

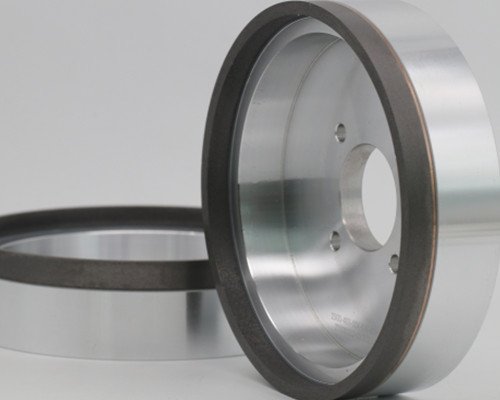

metal bond

14A1 Metal bond diamond wheel for grinding SCD tool, MCD tool

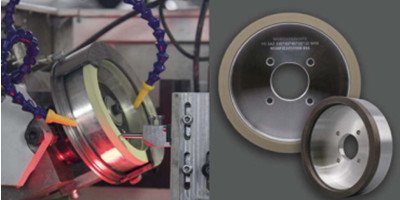

Example of grinding MCD tools with vitrified and metal diamond grinding wheel

| Grinding process | Grit |

| Coarse grinding | W40,W20 |

| Semi-finish grinding | W10,W5 |

| Finish grinding | W3.5, W2.5,W1.5 |

Grit selection for Single Crystal Diamons Tools grinding

| Grinding step | Grit |

| First step(Coarse grinding) | Using W40 vitrified diamond grinding wheel and then W20 or using W20 directly to improve grinding efficiency |

| Second step (Semi-finish grinding) | Using W10 (the chipping can achieve 0.01-0.013mm) |

| Third step(Finish grinding) | Vitrified/metal diamond grinding wheel (W10),Chipping can controlled 0.02mm |