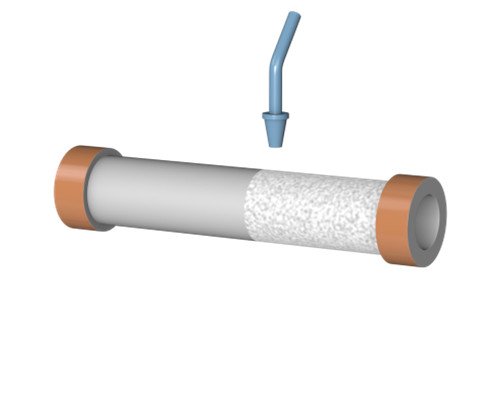

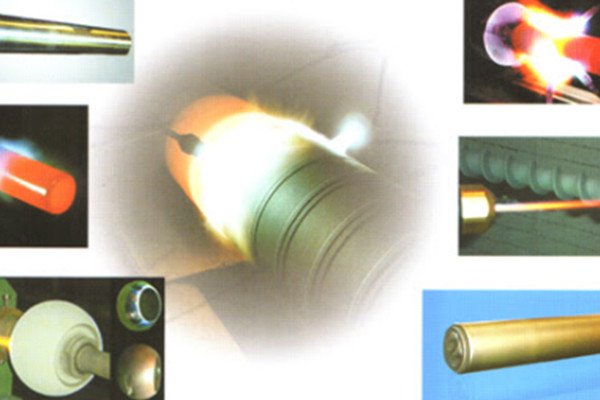

Thermal spraying is a metal surface processing method that sprays molten spray materials onto the surface of parts through high-speed airflow to form a spray layer. We call the special working surface “coating” and the working method of making the coating “thermal spraying”.

Common spraying methods include:HVOF,HAVF,SPS etc.

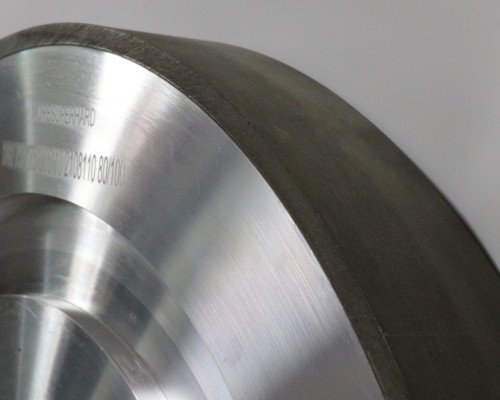

The material after spraying is relatively rough. Although it is only a thin layer, it has high hardness, high brittleness, and small processing allowance. Grinding is required to achieve a certain degree of accuracy and smoothness.

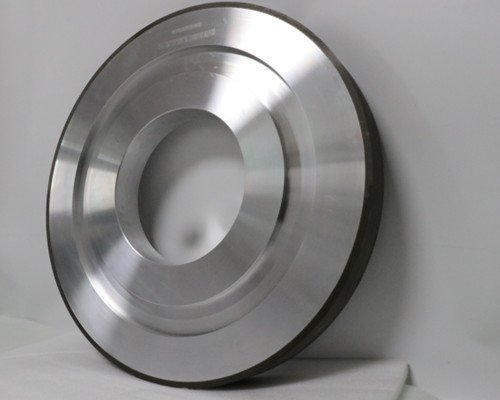

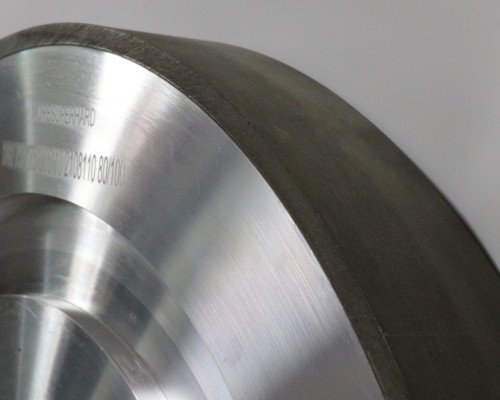

Resin bond diamond grinding wheels are most commonly used for thermal spray coating grinding. Resin bond diamond grinding wheels have the following advantages in coating grinding:

– Excellent elasticity and polishing effect.

– Once the mold is formed, it has good self-sharpening performance.

– Less clogging and dressing, high grinding efficiency

– High workpiece finish

– Low grinding temperature

Vitrified bond has good pore structure, high bonding strength and stable grinding performance, which is very suitable for grinding high hardness coatings such as ceramic coatings. Its grinding efficiency and life are better than resin grinding wheels.

Casting industry: divided into hydraulic (hydraulic pump, plunger, valve core) bearings, rotors, pressing rollers

Papermaking machinery industry: drying cylinders, ovens, rollers, corrugating rollers (after spraying treatment, the surface hardness of the corrugating roller can be increased to HV1200, and the working life of the corrugating roller can reach more than 40 million meters).

Textile industry: cloth guide rollers, printing roller surfaces

Printing industry: printing rollers, ceramic anilox rollers,

Metallurgical industry: process rollers for steel and non-ferrous metals

Electric power: ball mills, steam turbine rotors, generator rotors, cylinder surface repair, gas engine turbine blades, fan impellers,

Automobiles, aerospace and industrial gas turbines, 75% of engine parts need spraying, (turbines, seals, piston rings, support bearings)

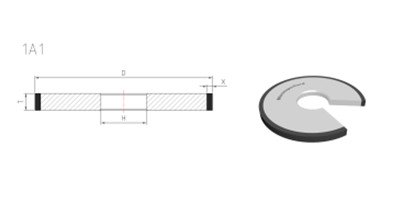

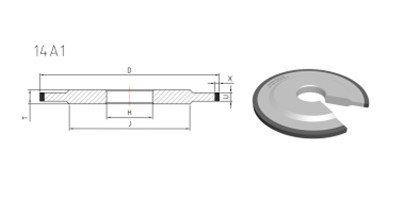

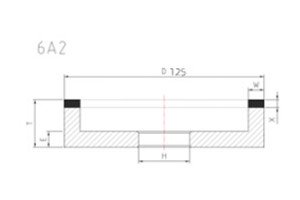

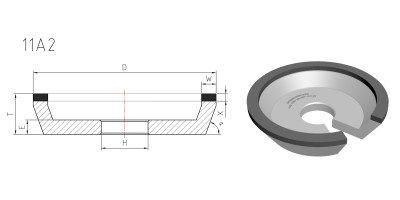

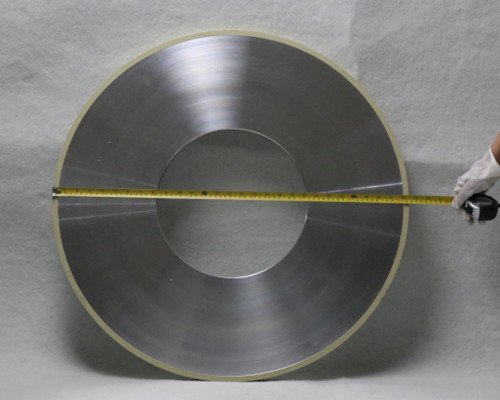

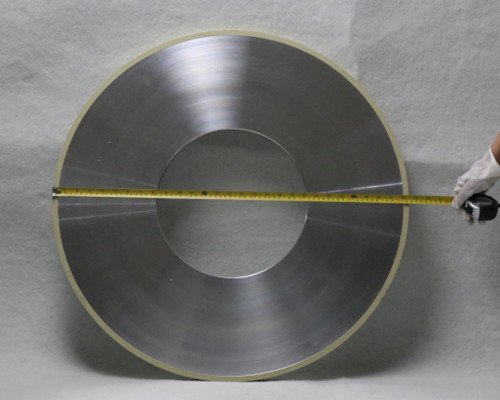

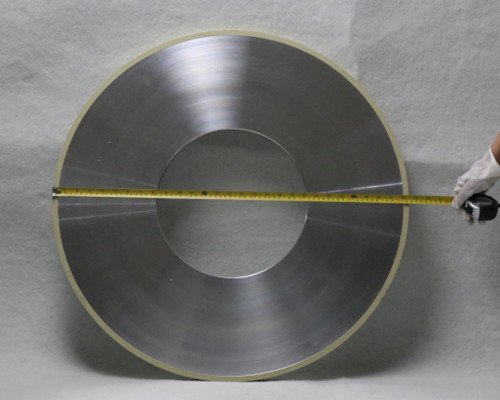

| Diameter (mm) | Diameter (inch) | H (mm) | T (mm) | X (mm) |

| 25 | 1 inch | 6 | 12 | 6 |

| 30 | – | 12 | 6 | – |

| 40 | – | 12 | 6 | – |

| 50 | 2 inch | 6 | 12 | 6 |

| 100 | 4 inch | 12 | 12 | 10 |

| 150 | 6 inch | 12 | 25 | 10 |

| 300 | 12 inch | – | 25 | 10 |

| 400 | 16 inch | 127 | 25, 50 | 10, 25 |

| 500 | 20 inch | 127, 203.2 | 25, 50 | 10, 25 |

| 600 | 24 inch | 254 | 25, 50 | 10, 16, 25 |

| 750 | 30 inch | 304.8 | 50 | 10 |

| 914.4 | 36 inch | 304.8 | 25, 50 | 10, 25 |

| 1100 | 43 inch | 304.8 | 50 | 10 |

| Other specification can be made according to customer requirement | ||||