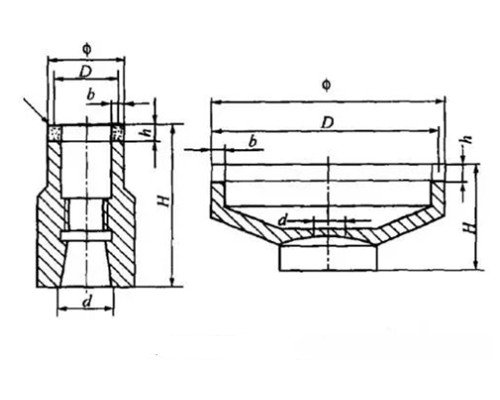

Diamond milling grinding wheel is divided into flat and spherical diamond milling grinding wheel.

Flat diamond milling grinding wheel

| Product Name | Flat Diamond Milling Grinding Wheel |

| Specification | Φ250,Φ300,Φ350,Φ400,Φ450,Φ480,Φ500 |

| Grit | 60/70-325/400 |

| Hole Diameter | Φ146,Φ230,Φ250,Φ360,Φ3 |

Spherical diamond milling grinding wheel

| Product Name | Sphere Diamond Milling Grinding Wheel |

| Specification | Φ3-Φ300 |

| Grit | 30/35-325/400 |

| Connector | Upon request |

The diameter of flat diamond milling wheel is usually more than 100mm, while that of spherical diamond milling wheel is less than 100mm.

The design of diamond grinding wheels enables them to adapt to various optical glass processing requirements. They usually use a high-hardness steel matrix to ensure sufficient strength and durability. In order to better adapt to the design of the internal threaded shank, the shank of the diamond grinding wheel is specially designed to match the specifications of the internal threaded shank. This design allows the diamond grinding wheel to be easily installed and disassembled, thereby improving processing efficiency and reducing operating difficulty.

Minimizes edge chipping on brittle glass materials

Maintains precise geometry during high-load machining

Improves process stability and productivity

Reduces tool change frequency and overall processing cost

We provide tailor-made metal bond diamond milling and grinding wheels based on:

Workpiece material

Machine model

Processing stage (rough / semi-finish)

Required surface quality and accuracy

Technical support is available to help optimize your grinding parameters.

When using a larger diameter diamond grinding wheel to process optical glass, higher grinding efficiency can be achieved by increasing the working line speed; however, the angle between the tool axis and the lens axis should not be too large to avoid accidental cracking of the grinding wheel due to excessive side pressure.

Looking for a reliable solution for optical glass machining?

Contact us to discuss your application and receive a customized grinding wheel recommendation.