Diamond pellets/fine grinding discs are mainly used for fine processing after rough processing of optical glass. Fine grinding discs generally use metal binders, and super fine grinding discs generally use resin binders. According to the physical properties of optical glass, using different types of binder fine grinding discs will achieve better processing results.

| Bond | Resin/Metal |

| Diameter | 3mm-20mm |

| Thickness | 3mm-15mm |

| Working surface curvature | According to your requirements |

| Grits | 400#-10000# |

| Concentration | 50%-150% |

Diamond pellets of various specifications such as φ6*4, φ8*5, φ10*5, φ12*3, φ15*5, φ16*3, etc. are mostly used for fine grinding of optical glass, polishing skin trimming, standard mold correction

Abrasive grits include W20, W14, W10, W7, etc.

High grinding efficiency, high precision, no scratches, long service life, effective stabilization of aperture; long single dressing cycle, good dimensional consistency of processed products.

Since the fine grinding process is between the rough grinding and polishing processes, it plays a key role in connecting the previous and the next processes. Therefore, it is particularly important to correctly select fine grinding discs with appropriate diamond grain sizes. The principle of selection is that the fine grinding discs used must be able to effectively remove the rough grinding marks left by the previous process, and ensure that the fine scratches produced by this process are completely eliminated in the subsequent polishing.

Ordinary telescope optical lenses:Generally, only one process is required with metal-based 1200# or 1500# (the surface roughness Ra value of the optical element reaches 0.16~0.32μm), and then polishing can be started.

Optical lenses for microscopes,cameras:Two passes of fine grinding are used, first with 1000# and 1200# metal bases for fine grinding, and then with 1500# or 1800# resin base pellets for the second pass of fine grinding (the surface roughness Ra of the optical element reaches below 0.10μm).

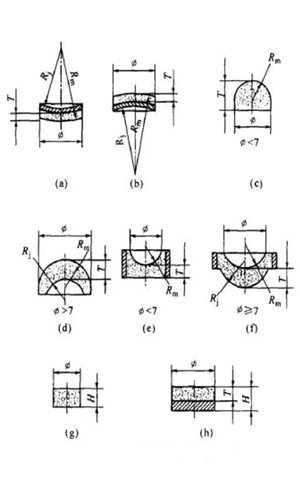

The size and trial range of the fine grinding disc are determined mainly from the curvature radius of the processed optical element and the surface area of the cast iron mold for pasting the pellets. The details are shown in the following table:

| Radius of curvature of optical element (mm) | 10-20 | 20-30 | 30-50 |

| Fine grinding disc surface area (㎠) | 6-25 | 25-50 | 50-100 |

| Finely grinding pellets size:Diameter*Height (mm) | Φ4*3 | Ф6*3/Ф8*3 | Ф8*3、Ф10*3(4)、Ф12*3(4) |

It is recommended to use a grinding disc with a smaller coverage (about 20%~30%) when processing flat or large spherical components. However, when arranging the pellets, the density of the pellets at the edge of the grinding disc should be slightly higher than that in the center. This will help to increase the pressure and increase the cutting force. Conversely, when processing small spherical components, a grinding disc with a larger coverage (about 30%~40%) should be used to ensure the stability of the mold surface.