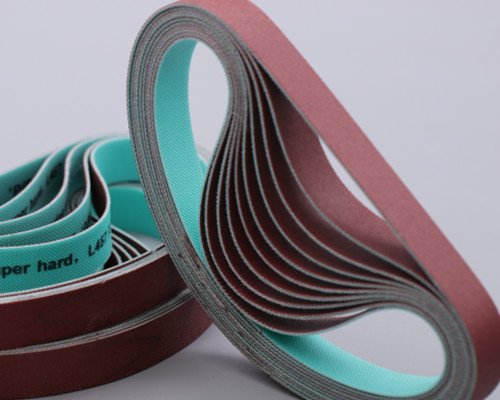

✅ Highly Wear-Resistant: 5-10 times longer lifespan than traditional aluminum oxide or silicon carbide belts

✅ Strong Cutting Power: Effectively removes burrs and smooths surfaces, reducing processing time

✅ Superior Surface Quality: Ensures uniform grinding without damaging the base material, improving aerodynamic performance

✅ Low Dust & Eco-Friendly: Reduces fiberglass dust, creating a safer working environment

🔹 Blade Edge Trimming – Removes mold burrs and optimizes blade edges

🔹 Surface Grinding – Enhances smoothness, reducing airflow resistance

🔹 Blade Defect Repair – Fixes cracks and bubbles, extending blade lifespan

🔹 Gel Coat Removal – Prepares old blades for recoating, improving adhesion

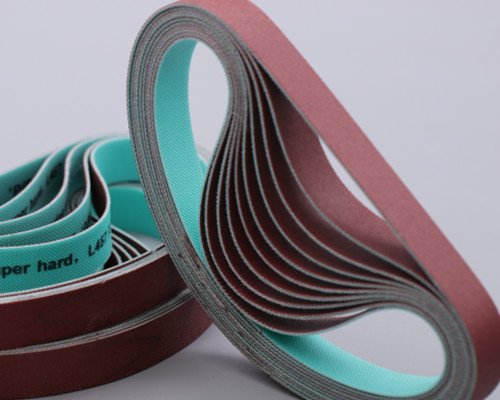

| Specification | Options |

|---|---|

| Abrasive Material | Diamond |

| Grit Size | 60# – 3000# |

| Backing Material | Cloth / Polyester |

| Bond Type | Resin Bond / Electroplated Bond |

| Belt Width | 10mm – 1400mm (Customizable) |

| Belt Length | 533mm – 4000mm (Customizable) |

| Compatible Equipment | Handheld sanders, automated grinding systems, stationary belt grinders |

Grit selection:

Coarse grinding (deburring, defect repair): 60#-120#

Medium precision grinding (surface homogenization): 150#-400#

Fine grinding (polishing, coating pretreatment): 600# and above

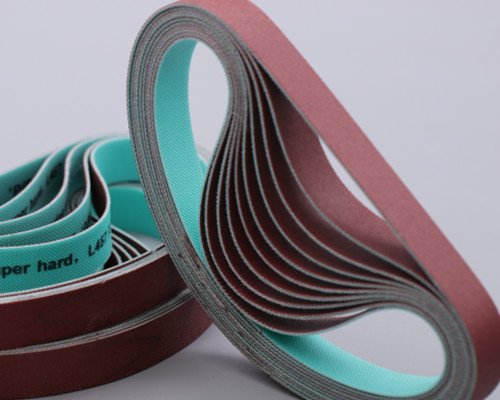

Base material selection:

Flexible cloth base: suitable for grinding complex curved surfaces or curved edges.

Rigid backing: suitable for flat or straight line repair, providing a more stable grinding effect.

📌 Custom production available – We offer different grit sizes, dimensions, and bonding systems tailored to your needs!

Customer Requirement:

This customer produces fiberglass wind turbine blades up to 80 meters long. Traditional sanding belts wore out quickly, leading to low grinding efficiency and production delays.

Solution:

We recommended 120# and 400# diamond sanding belts for rough grinding and fine finishing, paired with automated belt grinding equipment. This increased grinding efficiency by 30% and reduced belt replacement frequency by 60%, minimizing downtime and maintenance costs.

Customer Feedback:

✔ Belt lifespan increased 5 times, reducing replacement costs

✔ Grinding efficiency improved, reducing blade processing time by 25%

✔ Better surface finish, meeting aerodynamic design requirements

Customer Requirement:

This customer specializes in wind turbine blade maintenance and repair. They needed a solution for efficiently repairing surface cracks and removing old gel coatings while ensuring a smooth finish.

Solution:

We provided 240# and 800# diamond sanding belts for blade surface repair and finishing.

Customer Feedback:

✔ Repair cycle shortened by 40%, reducing maintenance costs

✔ Highly durable belts suitable for large-area repairs

✔ Low dust production improved workplace safety