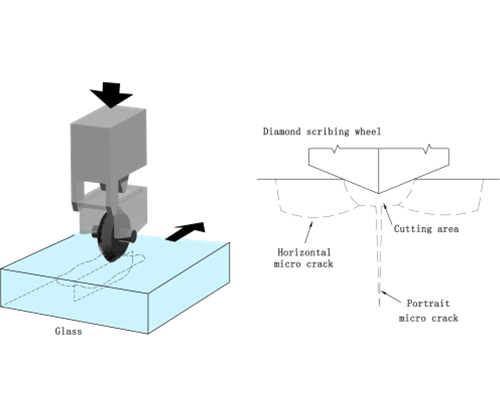

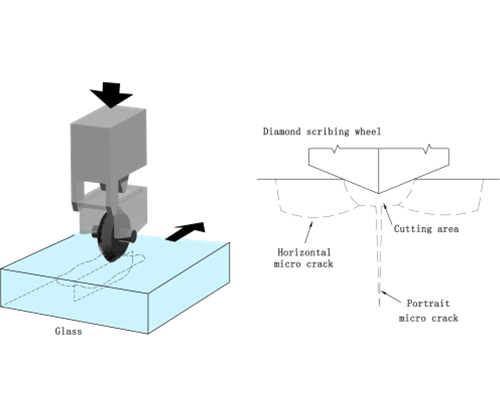

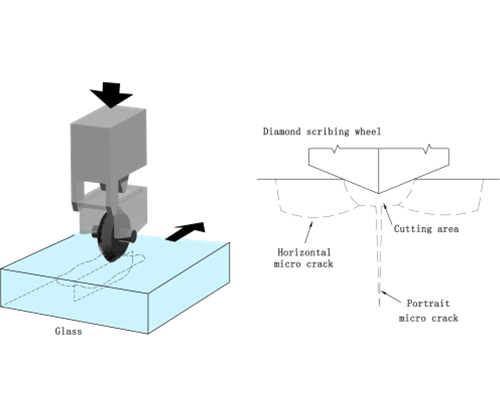

Diamond scribing wheels are precision cutting tools designed for accurate scribing and separation of brittle materials. They are widely used in display panel manufacturing, semiconductor glass processing, and touch panel glass cutting, where high consistency, clean scribing lines, and minimal chipping are required.

Our diamond scribing wheels are available in toothed edge and full-edge (continuous edge) designs to meet different glass thicknesses, cutting depths, and production stability requirements.

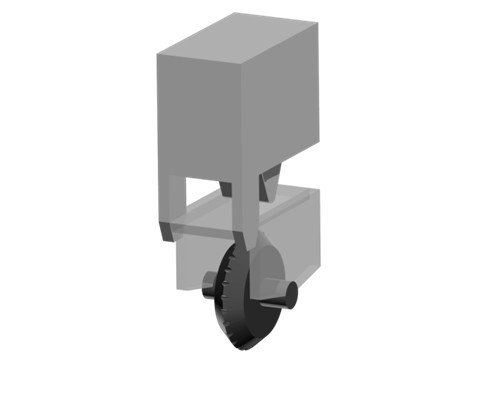

The toothed diamond scribing wheel features micro-tooth cutting edges that provide controlled penetration and stable crack initiation during scribing.

Key Features

Micro-tooth edge design for stable scribing force

Good balance between cutting efficiency and tool life

Suitable for standard and medium-precision glass scribing

Reliable performance in mass production

Recommended Applications

TFT-LCD display glass

Touch panel glass

Standard display glass substrates

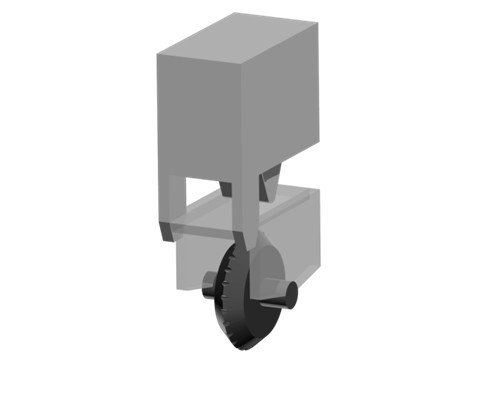

The full-edge diamond scribing wheel has a continuous cutting edge around the entire circumference, ensuring smooth and uninterrupted scribing lines.

Key Features

Continuous edge design for superior line consistency

Higher stability and cutting uniformity

Reduced chipping and improved edge quality

Ideal for high-precision and ultra-thin glass processing

Recommended Applications

OLED / AMOLED display glass

Thin and ultra-thin glass substrates

Semiconductor glass and high-precision optical glass

| Parameter | Range |

| Outer Diameter (OD) | 1.0 – 6.0 mm |

| Inner Bore (ID) | 0.4 – 1.5 mm |

| Thickness | 0.4 – 1.2 mm |

| Cutting Angle | 90° – 160° |

| Edge Type | Toothed edge / Full edge |

| Tooth Count (toothed type) | 80 – 400+ |

| Tooth Depth | 2 – 15 μm |

All specifications can be customized according to machine model, glass thickness, and scribing requirements.

High scribing accuracy and repeatability

Clean scribing lines with minimal edge chipping

Stable performance in high-speed and automated systems

Long service life and consistent cutting quality

We offer customized diamond scribing wheels based on customer requirements, including:

Wheel diameter, thickness, and bore size

Cutting angle and edge structure

Toothed or full-edge design

Matching cutter shaft solutions

Our engineering team can recommend the optimal scribing wheel configuration to improve cutting quality and production efficiency.

Looking for a Reliable Diamond Scribing Wheel Supplier?

Contact us to discuss your glass type, thickness, and machine parameters — we will provide a tailored diamond scribing solution for your application.

Challenge: The customer needed ultra-thin OLED glass (0.3–0.5 mm) to be precisely scribed without chipping or breakage, using high-speed automated scribing lines.

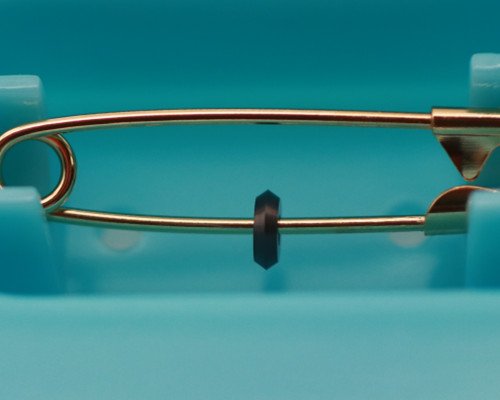

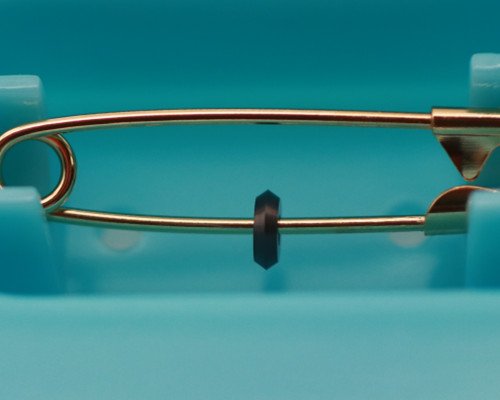

Solution: We supplied full-edge diamond scribing wheels with optimized edge geometry and custom diameter/bore sizes. The wheels were paired with precision cutter shafts for stable rotation.

Result:

Scribing quality improved with minimal chipping

Production yield increased by 15%

Tool life extended by 30%, reducing replacement frequency

Customer Case 2 – Touch Panel Glass Processing