Moresuperhard diamond wheel for precision grinding single crystal diamond, With Ultra-high precision. The PG seris is a CNC grinding machine for single or mono crystal diamond tool manufacture. The PG seris enables the automated production of ultra-high precision diamond tools.

Coborn PG series offers automated, ultra-high precision grinding, designed to meet the most complex of demands by toolmakers working with natural (MCD) or synthetic single crystal diamond (SCD), manufactured by either high pressure high temperature (HPHT) or chemical vapour deposition (CVD).

The applications of diamond grinding wheels

Diamond grinding wheels are used for grinding PCD cutting tools, PCBN cutting tools, CVD tools, MCD tools, milling cutter, reamer, drill and regrinding etc. It can be used for making facetted and convex radius tools using: natural diamond, HPHT, synthetic diamond, CVD synthetic diamond.

MCD tools are used for milling carbon steel, die steel, alloy steel, stainless steel, heat-resistant steel, gray cast iron, ductile iron, malleable iron, etc.

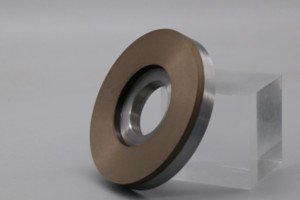

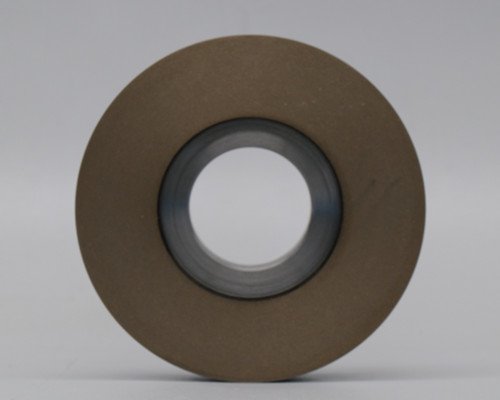

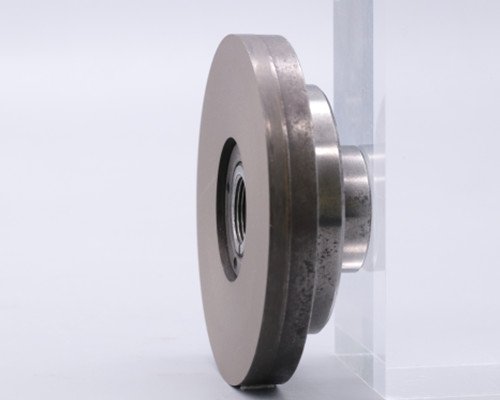

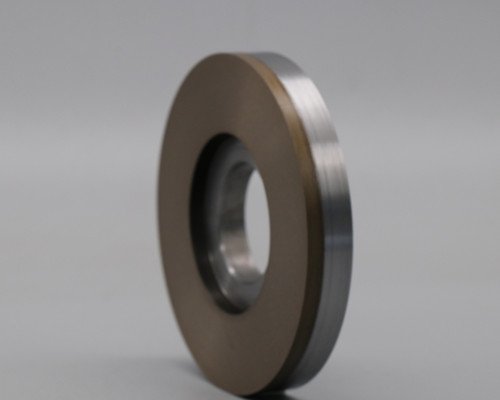

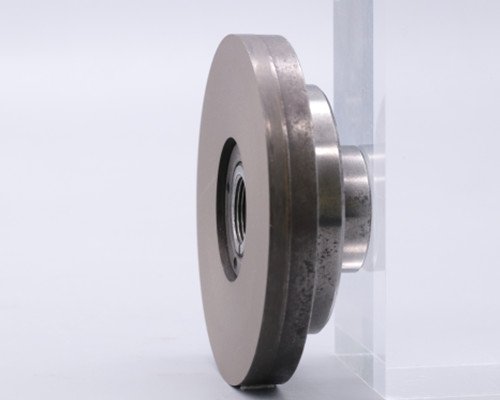

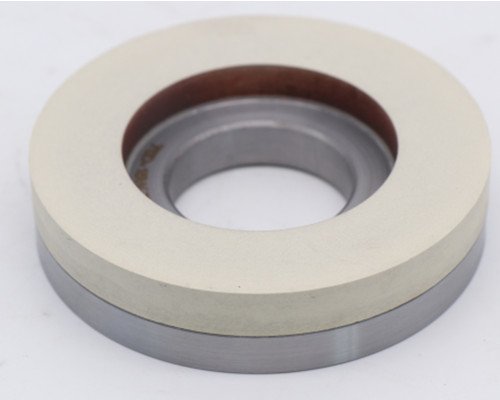

The specifications of diamond wheel for grinding single crystal diamond

| Model | D(mm) | T (mm) | H (mm) | W (mm) | X (mm) |

| 1A2 | 86 | 12 | 30.16 | 25 | 5.5 |

| 75 | 16 | 30.16 | 15 | 7.5 | |

| 85 | 12 | 30.16 | 20 | 5.5 | |

| Grit: 325/400, W10 (1500#), W5 (3000#), W3 (5000#) 2000# 3000# 10000# 15000# 20000# | |||||

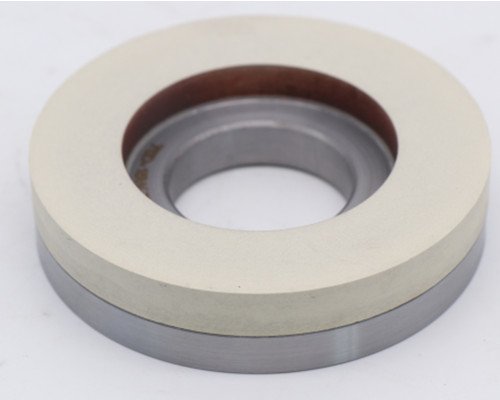

Vitrified Bond Diamond Grinding Wheel

Precision grinding for natural diamond (MCD) or synthetic single crystal diamond (SCD) cutting tools.

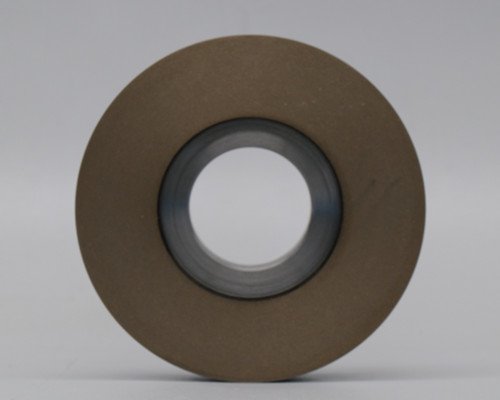

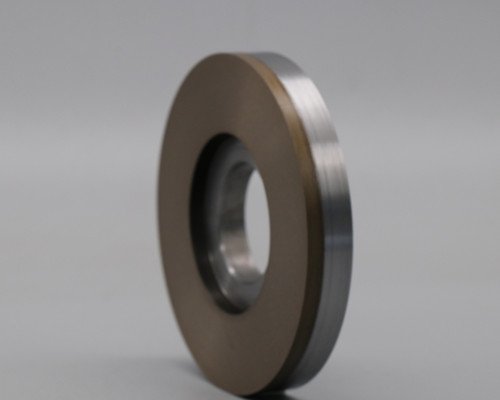

Metal Bond Diamond Grinding wheel

Natural (MCD) or synthetic single crystal diamond (SCD), manufactured by either high pressure high temperature (HPHT) or chemical vapour deposition (CVD). Metal bond diamond wheel can used for single crystal diamond tool manufacture with ultra-high precision.