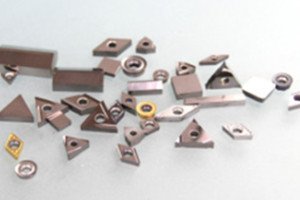

Widely applications of cermet inserts

Cermets are suitable for medium-duty machining, semi-finishing and finishing of various steel and cast iron parts. When the depth of cut (ap) is below 2.5mm, the feed per revolution (fn) is below 0.25mm/r, and the feed per tooth (fz) is below 0.20mm/tooth, the cermet cutting tool has excellent cutting performance.The amount of cermets inserts is very large, so it is necessary to improve the processing efficiency.

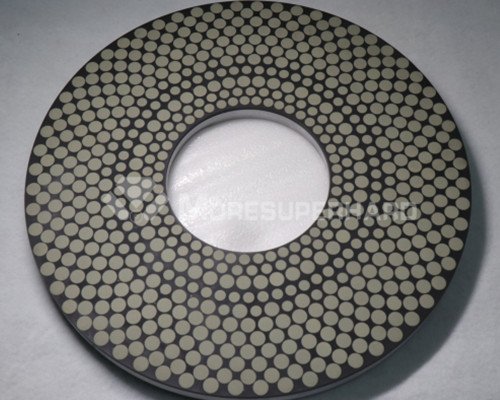

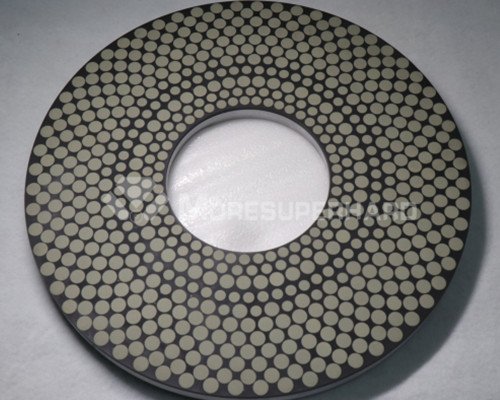

Double sided vitrified diamond grinding disc for batch of processing cermet inserts

Double sided grinding cermet inserts highly improve the processing efficiency and decrease the processing cost.

Products characteristic

1: [Abrasion resistance] 80–120 times that of ordinary grinding wheels

2: [Thermal conductivity] Good thermal conductivity of grinding, no workpiece burns

3: [High precision] The grinding workpiece has high precision and good surface quality

4: [High Efficiency]Sharp cutting, high efficiency

Products specifications

|

D(mm):300-1500 |

| W(mm):40-350 | |

| X(mm):3-10 | |

| Parallelism:<=2μm, Flatness:<=2μm, Roughness: Ra0.02μm-Ra0.2μm Durability: Grinding scribe (25mm*25mm), number of workpieces ≥ 1 million Cermet cutting edge, workpiece ≥ 1 million | |

Advantages of double-face grinding of cermet inserts

1. The grinding efficiency of the double end face is high, and the processing of two parallel end faces of the blade can be completed at one time, which reduces the traditional grinding process and eliminates the auxiliary time between processes.

2. The workpiece removal allowance is large and the workpiece allowance is gradually removed during the grinding process. The machining allowance that can only be removed by other grinding machines and grinding methods in several steps can be removed at one time.

3. High processing precision: double-end surface grinding passes through the rotary or linear feeding plate to upper and lower workpieces, and the dimensional accuracy and geometric accuracy of the double-end surfaces of the processed blades are high.

4. High degree of batch automation: double-end grinding are often used for stable production of large batches of workpieces, with stable processing quality and good workpiece consistency. High flatness and parallelism can be obtained (about 2um-4um)