Top and bottom finishing of carbide inserts, ceramic inserts, PCD and CBN inserts

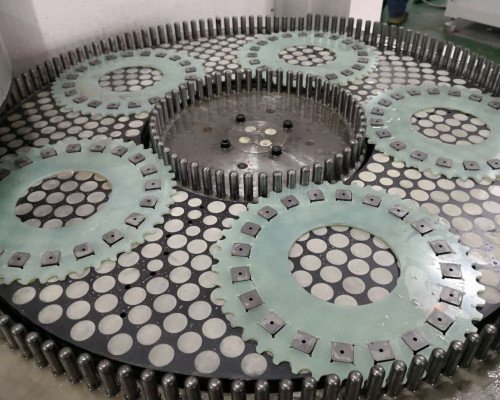

Moresuperhard supply full series resin bond, metal bond, vitrified bond diamond and CBN double disk grinding wheels for the top and bottom grinding. This flat grinding can achieve very high precision in height and parallelism, so it best choice for your PCD, PCBN, carbide, ceramic, cermet, and other materials cutting inserts. This double face grinding is much more efficient than normal surface grinding.

How to choose bond according to application of grinding wheel?

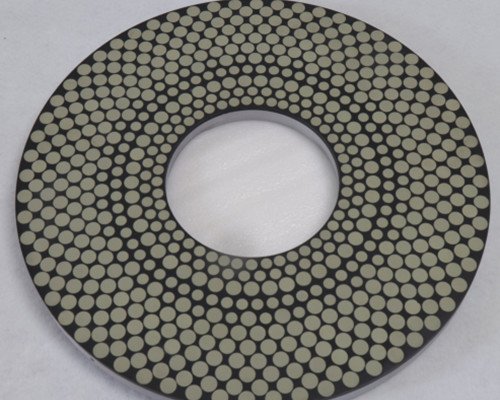

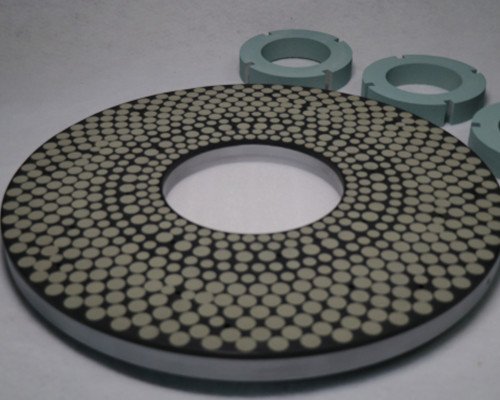

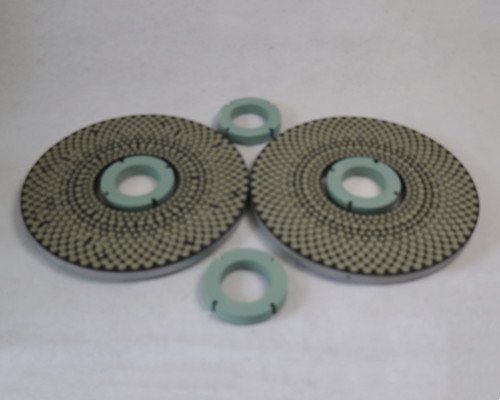

Resin bond diamond wheel : the grinding of carbide, ceramics (Al203, ZrO2,Si3N4, etc.) , cermet , Solid CBN, PCBN cutting insert top and bottom grinding

Vitrified bond diamond wheel : grinding of PCD, Solid CBN, PCBN insert, Automobile engine parts, air conditioner compressor parts, carbide cutting tools, PCD,PCBN cutting tools, alumina, zirconia ceramic products, precision bearings, hydraulic parts pneumatic components, measuring cutting tools, crystal, gemstone, silicon wafer and other products of double end grinding.

Advantages of Inserts Top and Bottom double disk Grinding Wheels

1.High grinding efficiency,Long service life and Good shape retention.

2. High strength synthetic diamond for high removal rates while excellent finish.

3. Sharp shape synthetic diamond for long dressing intervals.

4. Free cutting design for low cutting energy.

5. Better cutting edge with smaller chipping.

6. Good uniformity of size because the stable uniform structure and materials in abrasive layer.

7. High flatness, good finish, and parallemism.

8. Save your labor costs.

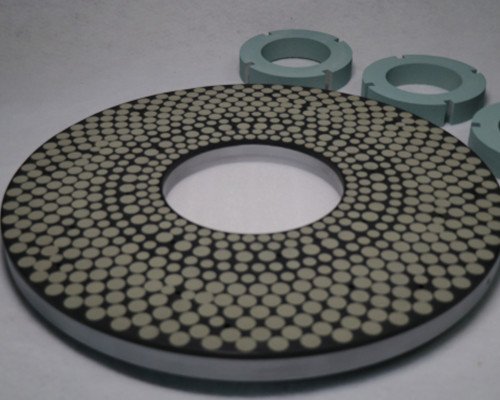

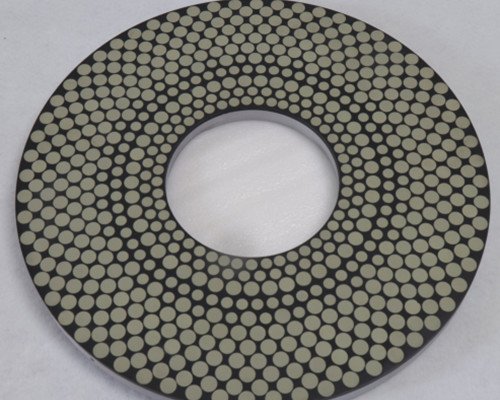

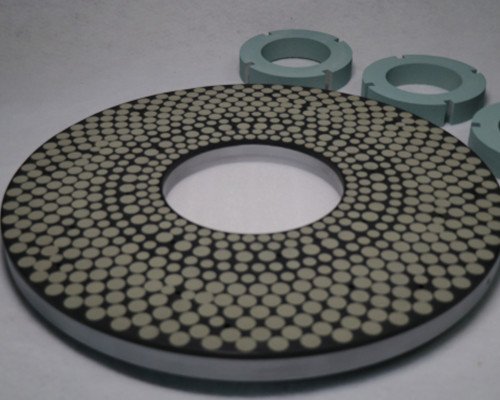

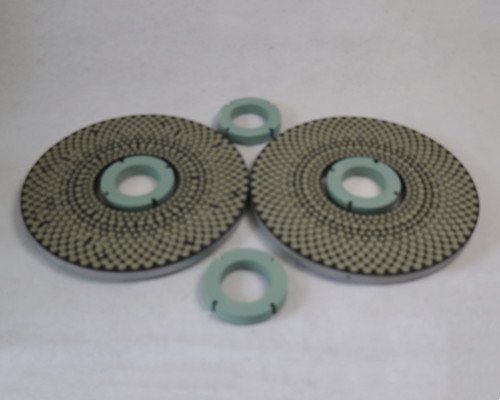

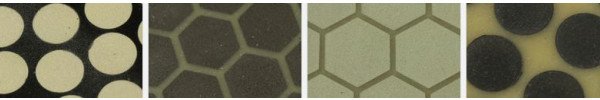

Shape of resin bond grinding segment: circular, straight segment (other shapes can be customized)

Shape of the vitrified bond grinding segment: regular hexagon, sector, square ,circular, trigonometrical, hexagonal pellets (other shapes can be customized)

Lapping Machine: Lapmaster, Wendt WBM, Viotoo, AMT, Stahli, Peter Wolters, Diskus, Agathon T&B, Fujisanki, Supfina, Melchiorre, Koyo, Lam Plan, Speedfam, Kemet, Gardner and other brands.

Moresuperhard diamond Double-Sided Flat Honing wheels can match all the popular single or double-side flat honing machines.

|

|

D: 300mm – 1500mm |

|

W(Abrasive layer width): 40mm – 350mm |

|

|

X( Abrasive layer height): 3mm -10mm |

|

| Flatness:<=2μm, parallelism:<=2μm, Roughness: Ra0.02μm-Ra0.2μm Durability: grinding HSS slide (25mm*25mm), the number of workpiece >= 1million grinding carbide blade, the number of workpiece >= 1million |

|

The dressing wheels are used for dressing diamond and CBN wheels. According to the different particle size, accuracy of the diamond and CBN grinding disc to choose the dressing wheel, making dressing easier and more time saving.