The electroplated diamond band saw is specially designed for precision cutting of advanced ceramics,including alumina, zirconia, silicon nitride, and silicon carbide. It combines high cutting accuracy,strong wear resistance, and low chipping rate, making it suitable for full-scenario deep processing

of ceramic products.

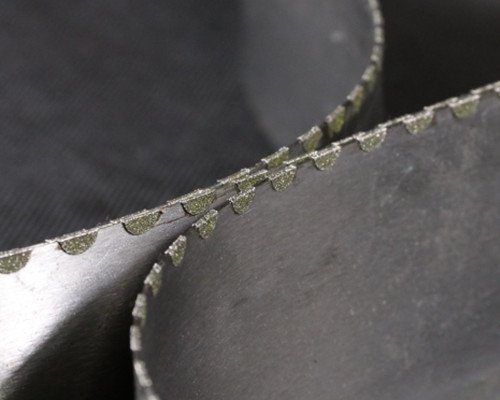

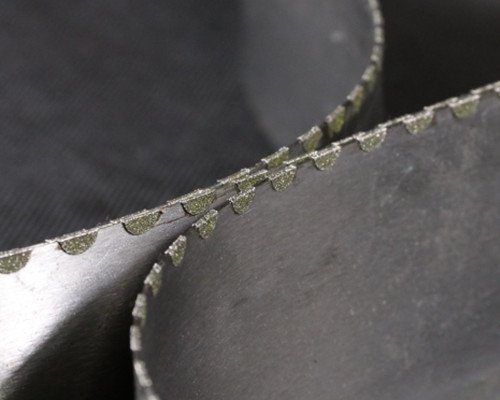

High-grade diamond abrasives are uniformly bonded to the band saw substrate through a precision electroplating process. The coating offers strong bonding strength and consistent diamond protrusion.The abrasive layout is optimized for the high hardness and brittleness of advanced ceramics,

ensuring smooth cutting surfaces with minimal chipping.

The band saw base is made of high-strength alloy steel and processed through leveling and tensionstraightening. Geometric tolerances are controlled at the micron level, providing excellent cuttingstraightness and preventing skew cutting or dimensional deviation, meeting the requirements of

precision ceramic components.

Diamond abrasives feature outstanding impact resistance and wear resistance, while the electroplatedcoating offers strong corrosion resistance. Compared with traditional cutting tools, the service lifeis increased by 3–5 times, significantly reducing tool replacement frequency and overall processing costs.

The cutting process produces low vibration, low noise, and no high-temperature burning.This prevents micro-cracks caused by thermal stress, ensures the structural integrity of ceramic workpieces,and reduces subsequent grinding operations.

Band width, thickness, diamond grit size, and band length can be customized according to customerrequirements. The band saw is compatible with various horizontal and vertical band saw machines,meeting cutting demands for different sizes of advanced ceramic components.

Designed for precision cutting of a full range of advanced ceramics, including but not limited to:

| Cutting Application | Recommended Length (in) | Recommended Width (in) | Recommended Thickness (in) | Recommended Grit | Typical Coating Thickness (in) | Compatible Equipment |

|---|---|---|---|---|---|---|

| Laboratory samples / ceramic substrates | 59.06–73.62 | 0.20–0.39 | 0.018–0.024 | 150#–200# | 0.006–0.008 | Benchtop / laboratory band saws |

| Ceramic bearings / tools / insulators | 78.74–88.19 | 0.59–0.98 | 0.028–0.031 | 100#–150# | 0.008–0.020 | Medium vertical / horizontal band saws |

| Ceramic plates / rods / tubes (general cutting) | 124.02–144.09 | 1.18–1.57 | 0.031–0.039 | 80#–120# | 0.008–0.020 | Large industrial band saws |

| Large-size or thick-wall ceramic batch cutting | 188.19–240.00 | 1.57–2.36 | 0.039–0.049 | 60#–100# | 0.020–0.024 | Heavy-duty / dedicated ceramic cutting lines |

General Notes:

1. Customization range: Length 47.24–393.70 in, Width 0.20–3.94 in, Thickness 0.016–0.079 in;

2. Joint types available: High-frequency welding or laser welding;

3. 1 inch = 25.4 mm, dimensions are accurate and consistent.

Full specification customization is supported. Based on customer cutting equipment models,

ceramic material properties, workpiece size, and accuracy requirements, band width, thickness,

length, diamond grit size, and electroplating process can be customized.

One-to-one cutting solutions and free sample testing are available.

| Cutting Tool | Electroplated Diamond Band Saw |

|---|---|

| Band Saw Size | 233” × 1.250” × 0.07” (5918 × 32 × 1.8 mm) |

| Diamond Grit Size | 40/50 |

| Workpiece Material | Alumina Ceramic (Al₂O₃) |

| Workpiece Thickness | 12 mm |

| Dimensional Accuracy | ±0.05 mm |

| Edge Chipping Control | < 0.15 mm |

| Surface Quality | Smooth surface, no secondary rough grinding required |

| Productivity Result | Shortened machining cycle and improved production efficiency |

| Overall Benefits | Reduced tool change time, improved surface finish and dimensional accuracy, lower edge chipping rate, higher material utilization, reduced processing cost |