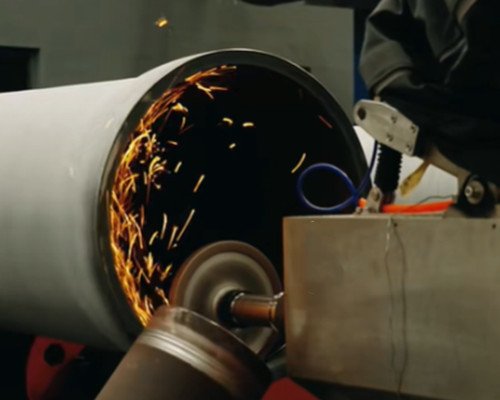

Ductile iron pipe is a new type of metal pipe. It has the corrosion resistance of cast iron pipe and the toughness and strength of steel pipe. It also has the advantages of impact resistance, vibration resistance and thin wall. It is widely used in urban water supply, drainage and gas transmission projects.

Remove casting defects: remove burrs, scale and other defects on the surface to improve the quality of the pipeline.

Improve surface finish: ensure that the pipeline surface is flat, which is convenient for sealing and precision connection.

Eliminate stress and microcracks: reduce stress concentration points and extend the life of the pipeline.

Improve corrosion resistance: the surface is smooth after grinding, reducing the risk of corrosion and improving the adhesion of protective coatings.

Improve dimensional accuracy: ensure the accurate size of key parts for easy installation.

Facilitate coating treatment: prepare for subsequent anti-corrosion or coating treatment.

1. High hardness and strong wear resistance

2. High precision and good sharpness

3. Fast heat dissipation to avoid workpiece burns

4. Suitable for dry grinding

5. Good shape retention

6. Efficient grinding

Available in any form, and in a variety of grit sizes

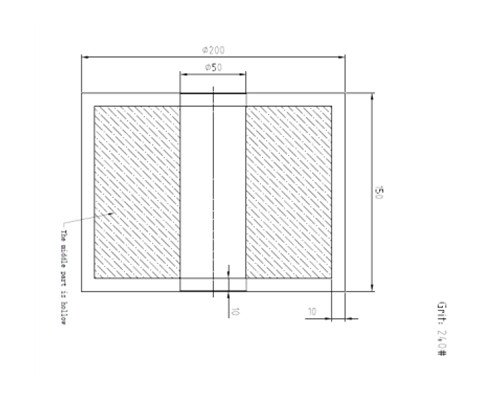

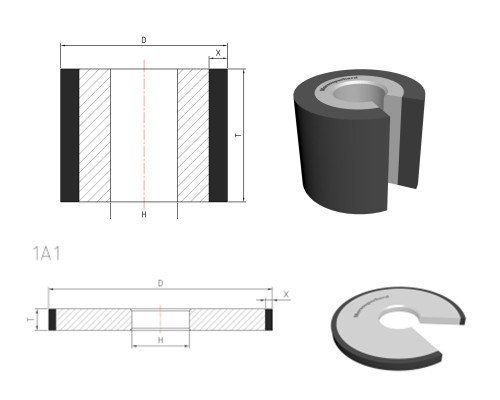

Grinding wheel type: Electroplated bond diamond grinding wheel

Workpiece: Ductile iron pipes (DI Pipe)

Size: D200xH50xT150mm

Grit size: 240#

Special designing: Make the grinding wheel steel body middle part is hollow to reduce weight, it can help customer fit the grinding wheel on their machine, also save shipping cost.