The high frequency induction brazing machine has advantages of induction heating speed, high efficiency, energy saving and low cost, the small oxidation area and the full solid welding, etc

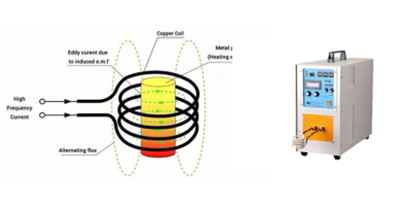

Working principle diagram of high frequency induction welding machine

Applications of High Frequency Induction Brazing Machine

– Diamond PCD and PCBN tools, diamond saw blade brazing, sawtooth welding

– Brazing/welding of carbide tool ( such as turning tool, milling cutter, drill hot rolling, pliers, hammer, wrench, cutting pliers, etc)

– Composite brazing/ welding of metal materials. Heat treatment of auto and motorcycle parts, hot piers of standard parts, nut hot piers, copper standard heating

– Glass steel alloys frame brazing, small bearings quenching, annealing etc.

– Jewelries brazing, watchcase annealing and clock outer quenching.

– Electronics products brazing/welding/heating

– Precise mechanical parts brazing/heating.

– Stainless steel strip annealing etc.

– Melting of gold, silver, copper, brass of little amount

Technical Parameters of High Frequency Induction Welding Machine

| Input Voltage | Single phase 220v 50-60HZ ,

Three-phase 380V /50HZ |

| Output oscillatory power | 3- 35kw |

| Oscillation frequency | 30-50Khz |

| Current input | 2-60A |

| Duty cycle | 100% 40° |

| Type

|

WH-VI-16 |

| Input powder | 16KW |

| Input voltage | One phase 220V;50-60Hz |

| Oscillation frequency | 30-50KHz |

| Cooling water pressure | ≥0.03MPa |

| Weight | 24kg |

| Dimensions | 225×480×450mm |

| Type

|

WH-VI-26 |

| Input powder | 26KW |

| Input voltage | Three phase 380V;50-60Hz |

| Oscillation frequency | 30-50KHz |

| Cooling water pressure | ≥0.05MPa |

| Weight | 60kg |

| Dimensions | 265×600×540mm |

Applications of High Frequency Induction Brazing Machine:

* Welding of carbide tool ( such as turning tool, milling cutter, drill hot rolling, pliers, hammer, wrench, cutting pliers, etc)

* Welding of diamond tool head (such as welding of diamond saw blade, abrasive tool and sawtooth welding)

* The drilling bit welding

* Composite welding of metal materials. Heat treatment of auto and motorcycle parts, hot piers of standard parts, nut hot piers, copper standard heating

Step 1: Welding Preparation

Welding powder, Silver / copper foil , pcd / pcbn blanks, cutter body .

Between the cutter body and pcd & pcbn blanks put into the Silver / copper foil and Silver/ copper powder .

*CBN inserts with copper foil , 850~900℃

*PCD inserts with Silver foil , 600℃

Step 2 : High frequency induction welding machine

Step 3 : Brazing / Welding

Opening the water and electricity of high-frequency welding machine . Then opening the panel. Putting the cutter body into the sensor, pressing the remote control switch, starting heating. When the workpiece is heated to 830-860 ℃, copper foil melting and filling weld.

Finally, pressing the “Stop” button to stop heating.