What’s the single crystal diamond plates

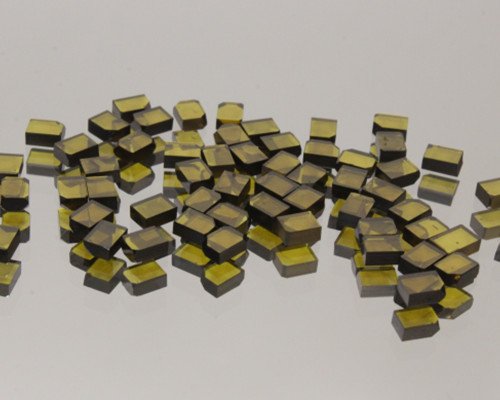

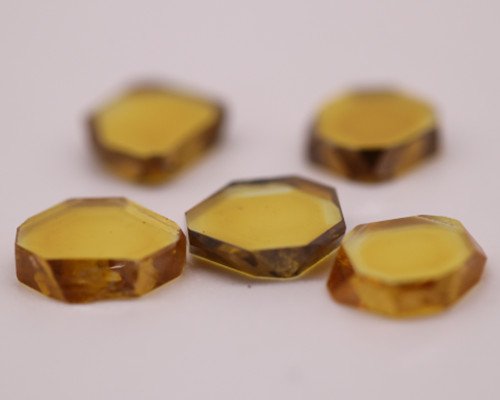

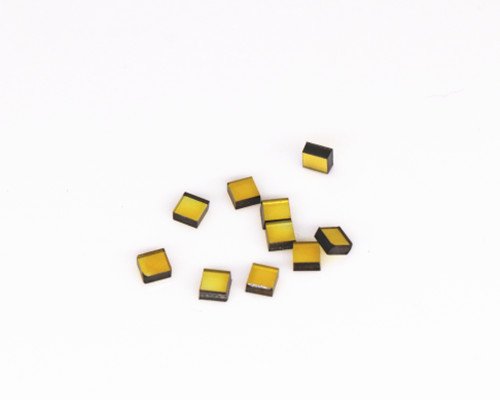

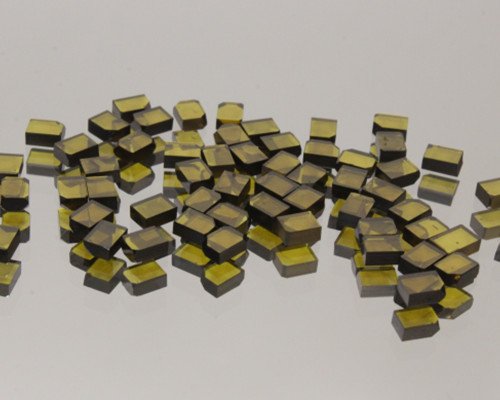

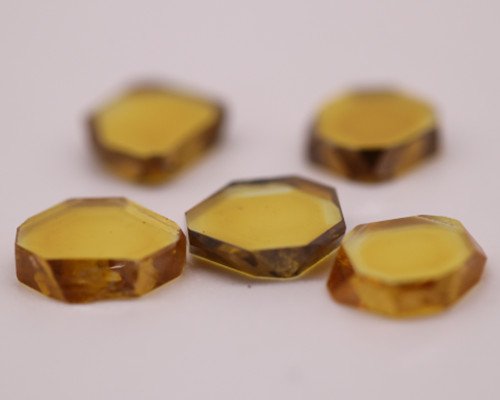

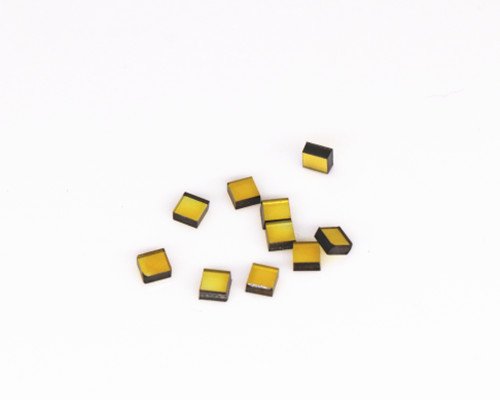

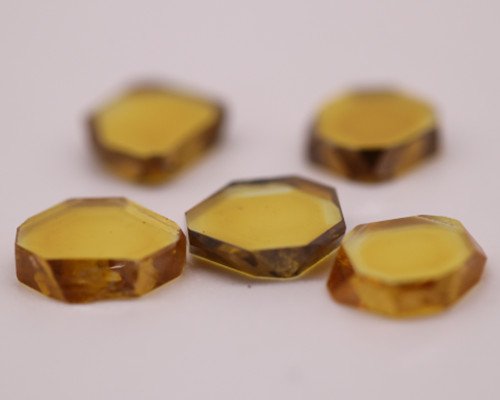

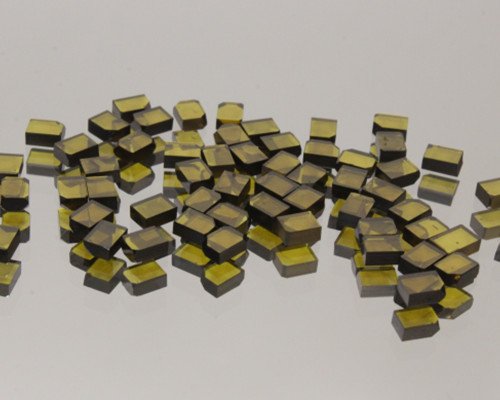

HPHT single crystal diamond are synthetic diamonds produced by high pressure high temperature synthesis under tightly controlled growth conditions. More Super Hard mainly produce industrial-grade single crystal synthetic diamond plate. The shapes of mcd diamond plates include round shape, square shape, rectangle and hexangle shapes,etc.

HPHT single crystal diamond plates are divided into Grade A, Grade B and Grade C

Grade A: with precise laser cut edge, no missing angle, clean crystal, without any inclusions under the microscope

Grade B: a lack of angle,can see the minimal inclusions under the microscope

Grade C: a lack of angle, can see the visible inclusions and scrap inside under the lights

Specification of HPHT single crystal diamond plate

| No. | Shapes | Size(mm) | Thickness(mm) | Orientation |

| SCD12 | Near Square | 1-4.5 | 0.3-1.7 | 4pt, 2pt

<100> <110> <111> |

| SCD22 | Near Square | 1-4.5 | 0.3-1.7 | |

| SCD13 | Near Hexagon | 1-8.0 | 0.3-1.7 | |

| SCD23 | Near Square | 1-8.0 | 0.3-1.7 | |

| SCD33 | Near Square | 1-8.0 | 1.0-1.2 | |

| SCD11 | Rectangle/Triangle Round/sex-angle ect | 0.3-5.0 | 0.3-1.7 | |

| Special size can be customized (such as 1 x 2 x 3, 1 x 1.2 x 4, 1.2 x 3 x 4, 1.2 x 4 x 5, 1 x 1 x 4, 1 x 1 x 5, 1 x 2 x 4, 0.5 x 2 x 4, 3.2 x 3.2 x 1.2, 1 x 1.5 x 3mm ) | ||||

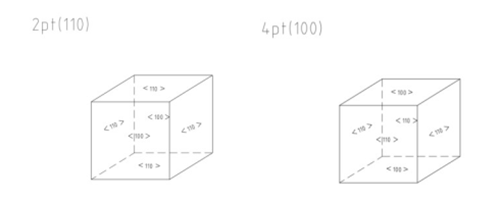

Single Crystal orientation

2pt(110): top and bottom 110+2 sides 110+2 sides 100

4pt(100): top and bottom 100+4 sides 110

Moresuperhard hpht mono crystal diamond plates comprehensive mechanical range

| Generic application | Crystal growth process | Primary application |

| Cutting tools wear part | Single crystal CVD – colourless ( low nitrogen content) | Ultra precision machining acrylics, copper, germanium. Generates very high surface finishes |

| Poly-crystalline CVD – Opaque (Low nitrogen content) | Wide-ranging laser cut shape and size for precision machining of MMC and CFRP materials | |

| Wide-ranging laser cut shape and size for precision machining of MMC, CFRP and woodworking materials. | ||

| Single crystal HPHT – pale yellow (Medium nitrogen content) | Long edge length requirements (e,g. profile tools) | |

| Long edge length requirements (e,g. controlled waviness tools) | ||

| Engineered cutting tools and wear parts for super-finishing, burnishing and wire guides

Convenient cut shapes(rectangle, triangle, round) |

||

| Super-finishing and precision machining e.g.

Precious metals and MMC materials |

||

| Dressing

|

Single point, multipoint, blade, roller and rotary dressing | |

| Chisel dressing chisel form dressing | ||

| Poly-crystalline CVD – Opaque (Low nitrogen content) | Strong and more wear resistant grade for single point and blade dressers | |

| General purpose grade for cutting tools and rotary dressers | ||

| Wire Drawing | HPHT Pale Yellow (Medium nitrogen content) | Wire drawing of ferrous, non ferrous precious and refractory metals |

– Ultra precision cutting tools for non-ferrous and non-metallic materials , specialty tools (cutter, turning tools, carving tools,angle tools). The mono-crystal diamond tools can achieve excellent cutting edge by grinding . And the surface finish can reach 0.025 micron or higher. Mono-crystal diamond tools are often used for…

– Micromaching for free form production of single crystal diamond lenses

– Monocrystalline diamond for wire dies

– Optical industry: optical lenses, (aspheric) spherical lenses, optical glass, optical molds, mirrors, etc.

– Printing industry: roller mould

– Automotive industry: night driving optical system, projection lights, aluminum alloy wheels, etc.

– 3C industry: mobile phone outer mirror / button mirror / torch outer mirror, computer hard disk substrate, etc.

– Electronic appliances: computer hard disk substrate, etc.

– Defense industry / aerospace: navigation gyro for missiles, etc.

– New materials: ceramics, engineering plastics, etc.

– Medical equipment: contact lenses, accelerator electron guns, etc