• The ground workpiece has high precision and good surface quality

• Good shape retention of the workpiece

• High grinding efficiency

• Small grinding force and low grinding temperature

Procession of wafer thining

Wafer thinning generally uses wafer rotation grinding, and the processing process includes rough grinding and fine grinding. The axial feed speed of rough grinding is high, and a diamond grinding wheel with a larger particle size is used to quickly remove about 90% of the machining allowance; the axial feed speed of fine grinding is small, and a diamond grinding wheel with extremely small particle size is used. , there are two purposes of fine grinding: one is to remove the remaining 10% machining allowance, and the other is to eliminate the damage layer caused by rough grinding.

| Model | D (mm) | T (mm) | H (mm) |

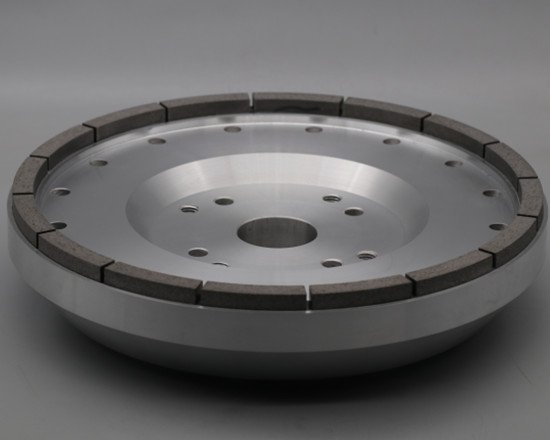

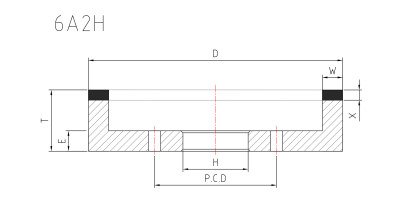

6A2/6A2H 6A2/6A2H |

175 | 30, 35 | 76 |

| 200 | 35 | 76 | |

| 350 | 45 | 127 | |

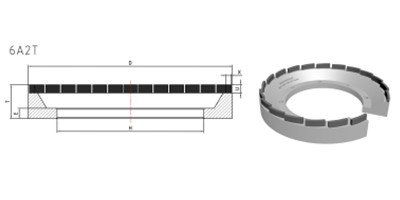

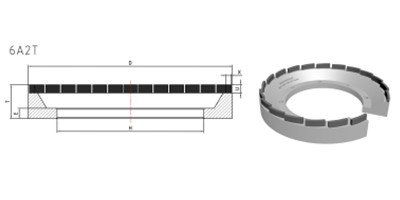

6A2T 6A2T |

195 | 22.5, 25 | 170 |

| 280 | 30 | 228.6 | |

6A2T(three ellipses) 6A2T(three ellipses) |

350 | 35 | 235 |

| 209 | 22.5 | 158 | |

| Other specifications can be produced according to customers’ requirement. | |||