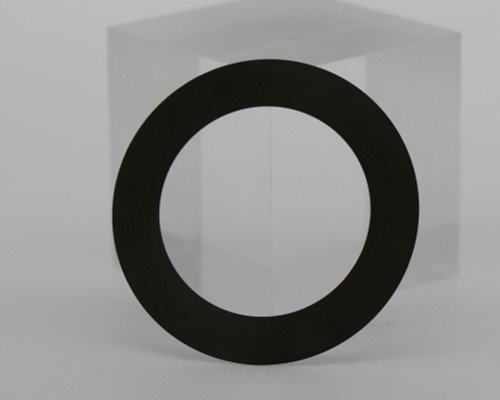

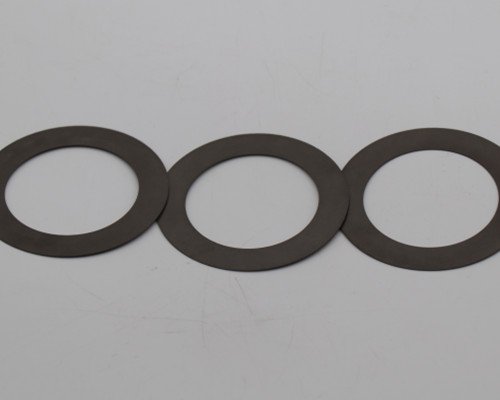

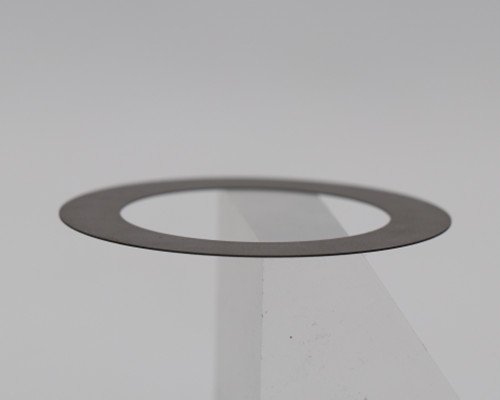

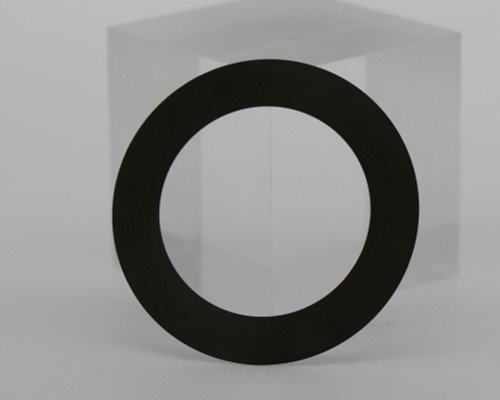

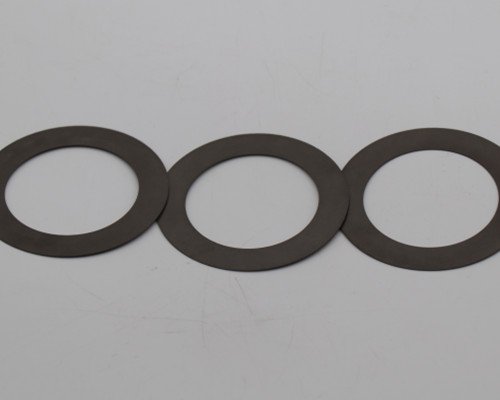

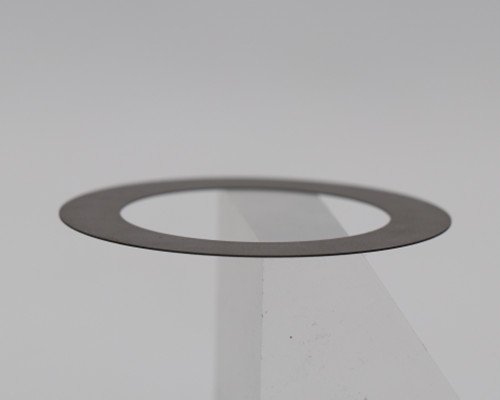

Metal diamond dicing blades are made of high-quality diamond or cubic boron nitride (CBN) sintered with metal binders. Metal diamond dicing blades has the characteristics of thin thickness and high precision. It is mostly used for high-precision grooving and cutting of electronic components, optical components and other materials.

Applications of metal diamond dicing blade

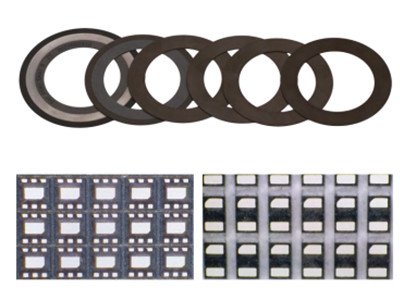

Semiconductor packaging: BGA, LGA, LED, diode, etc.

Glass materials: silica, optical glass, coated glass, quartz glass, etc.

Ceramic materials: silicon carbide, zirconia, crystal, sapphire, etc.

Metal materials: quenched steel, NdFeB, silicon ferromagnetic, stainless steel, etc.

![]()

Features of diamond dicing blades

Metal diamond dicing blades has strong holding power for abrasive grains, so it has high wear resistance and is suitable for precision machining of materials.

Optimized abrasive grain distribution can effectively reduce oblique cutting and serpentine cutting

Precise control of concentration, suitable for a variety of material applications

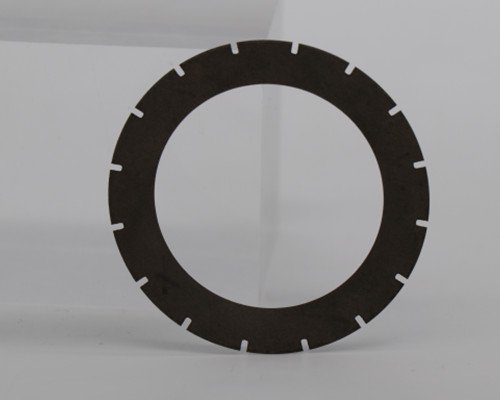

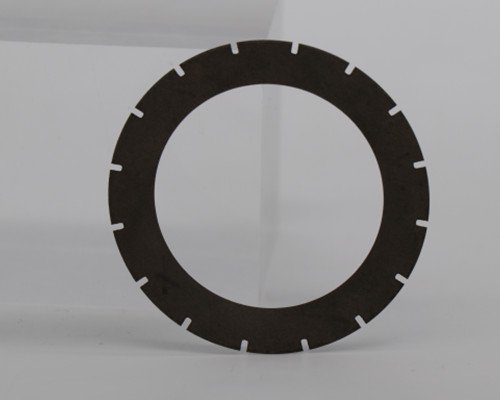

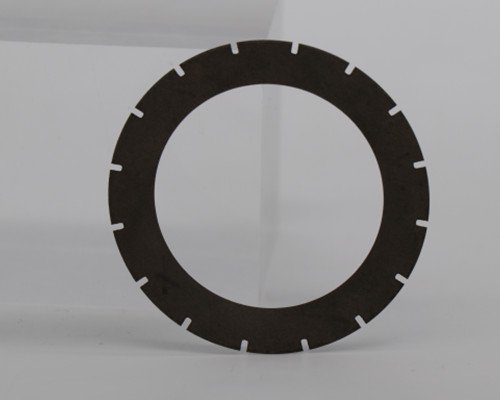

Open tooth processing can effectively improve cutting quality and blade service life.