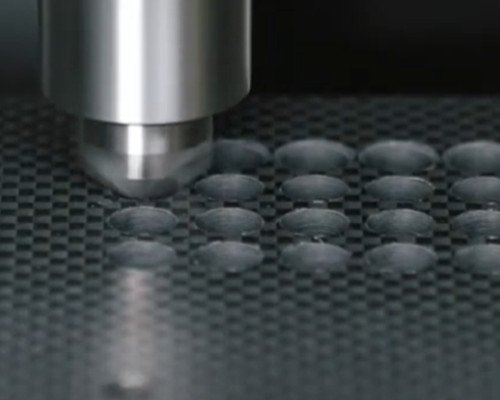

Polycrystalline Diamond (PCD) countersink drills are high-performance tools designed for precision machining in demanding industries such as automotive, aerospace, and battery manufacturing. Especially suited for aluminum alloy and carbon fiber composite structures, they deliver unmatched tool life, dimensional accuracy, and machining efficiency, making them ideal for battery housings of new energy vehicles (NEVs).

Exceptional Wear Resistance: PCD cutting edges maintain sharpness and surface finish over long tool life.

High Precision: 2A thread accuracy with tight dimensional tolerances (hole accuracy ±0.03 mm; surface roughness up to Ra0.4).

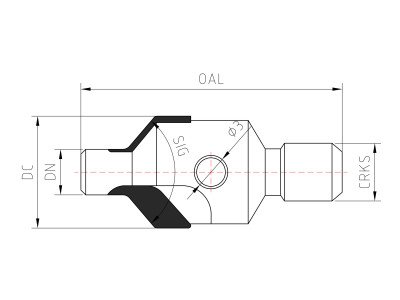

Countersink angles: 90° / 100° / 120° / 130°

Guide column diameter: φ2–φ16 mm (custom available)

Composite Tool Design:One-step drilling, countersinking, and chamfering

Reduces tool change time by up to 70%

Mirror-Finish Cutting Edge: Laser-polished Ra0.01 μm for ultra-low friction and anti-adhesion.

Cold Laser Processing: Achieves cutting edge profile accuracy of ≤5 μm

Battery housings (NEV battery boxes, especially 4680-type)

High-silicon aluminum castings (AlSi12 die-castings)

Carbon fiber composites (T800-grade CFRP)

Sealing surfaces of battery cases

Drilling and countersinking of laminated materials (Al + CFRP)

Tool life: Up to 12× longer than carbide tools

Cutting speed: Up to 300 m/min on AlSi12

Hole accuracy: Stable at ±0.03 mm

Efficiency boost: Reduces machining time by over 30%

Delamination-free machining on CFRP

Burr-free, smooth surface finish on aluminum alloys

| Model | DN(mm)

|

DC(mm)

|

SIG | OAL(mm)

|

CRKS | ZEFP |

|

2.5 | 10 |

100°

|

30

|

M6*1.0

|

2 |

| 3 | 10 | 2 | ||||

| 3 | 12 | 2 | ||||

| 3 | 14 |

32

|

M8*1.0

|

2 | ||

| 4 | 17 | 3 | ||||

| 6 | 19 | 2 | ||||

| 8 | 22 | 3 | ||||

| 8 | 25 | 2 | ||||

| 2.5 | 10 |

130°

|

30

|

M6*1.0

|

2 | |

| 3 | 10 | 3 | ||||

| 3 | 12 | 2 | ||||

| 3 | 14 |

32

|

M8*1.0

|

2 | ||

| 4 | 17 | 3 | ||||

| 6 | 19 | 2 | ||||

| 8 | 22 | 3 | ||||

| 8 | 25 | 2 |

Battery Tray Machining

Customer: Leading battery manufacturer

Process: Drilling + countersinking in one step

Result: Single-piece cycle time reduced to 3.2 minutes

4680 Battery Box

Material: Carbon fiber laminate

Solution: PCD countersink drill with 5MPa internal coolant

Result: Layer thickness kept < 0.2mm; precision ±0.03 mm