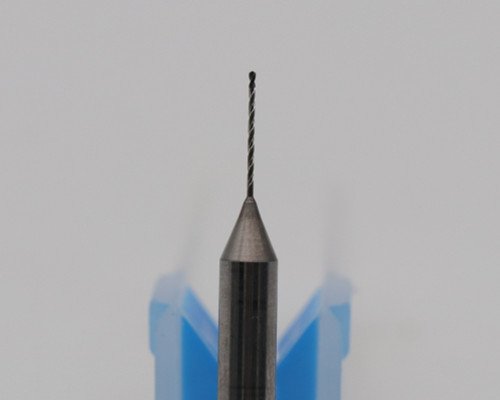

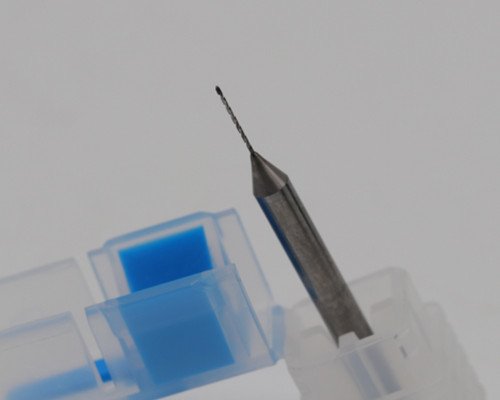

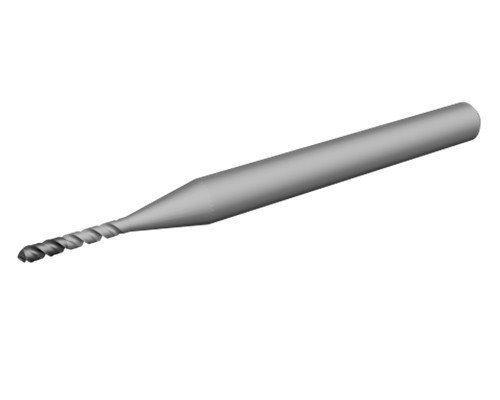

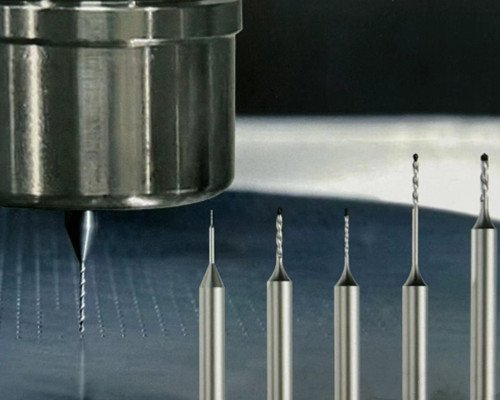

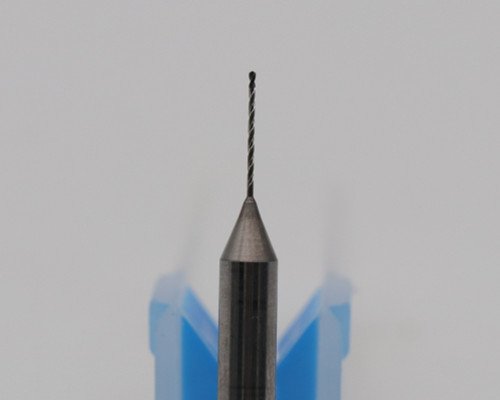

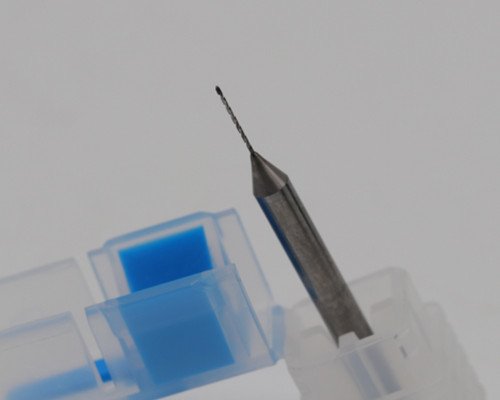

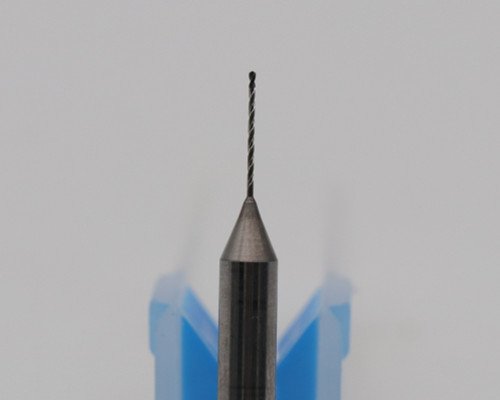

PCD micro drills are widely used in semiconductors, aerospace, 3C industry, chips, medical equipment and other fields. They are suitable for processing high hardness, high wear resistance, and high brittleness materials such as quartz, single crystal silicon, polycrystalline silicon, ceramics, graphite, sapphire and titanium alloys. They are particularly suitable for processing micro holes with a diameter of Ф0.1 to Ф3.

High hardness and high wear resistance: PCD micro drill uses polycrystalline diamond material, which has extremely high hardness and wear resistance, which makes it perform well when processing high hardness and wear-resistant materials, such as quartz, single crystal silicon, Polycrystalline silicon, ceramics and titanium alloys, etc.

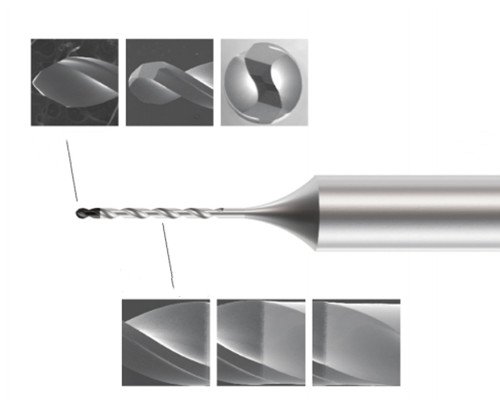

Excellent drilling accuracy: Through special drill tip design and high-precision manufacturing (up to 5μm), PCD micro drilling can ensure that the diameter tolerance, roundness and straightness of the hole reach extremely high standards, meeting the needs of precision machining.

Excellent hole wall and hole opening quality: The PCD drill tip’s low friction coefficient and low affinity with non-ferrous metals and non-metallic materials can effectively reduce built-up edge and maintain the smoothness of the hole wall. In addition, it can also reduce hole chipping and cracks when processing hard and brittle materials, and avoid defects such as hole burrs when processing sticky materials.

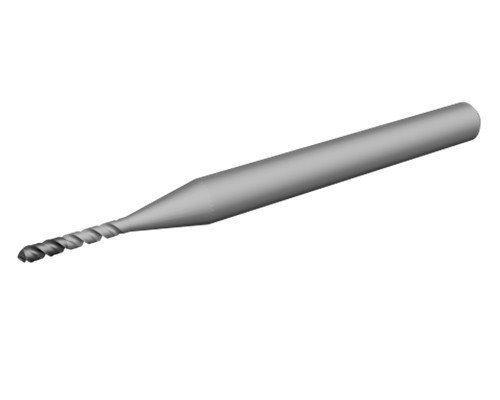

High aspect ratio: The design of the PCD micro drill allows it to cope with different aspect ratio requirements, up to 53 times, which makes it very useful in machining that requires extremely deep holes.

Extended tool life: Compared with traditional carbide drill bits, the service life of PCD micro drills can be significantly improved, especially when processing difficult-to-machine materials, and its life can be extended by 50-100 times.

| Specification Table | ||||||||

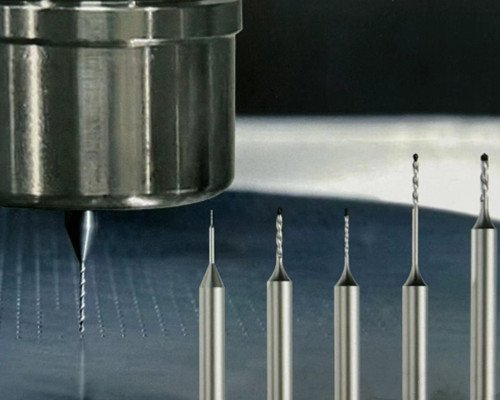

| Series | Specification | d1(mm) | L2(mm) | L2/D | D2 | L | α | Application |

| MSH-CT-D1 | d1*L2*SD3.175*L*α | 0.2-≤0.4 | 2~6 | 32 | 3.175 | 38/45 | 110°-130° | Graphite, polymer wear-resisting material, aluminum alloy, and other non-ferrous metals |

| 0.4-≤0.8 | 4~13.5 | |||||||

| 0.8-≤2.0 | ||||||||

| MSH-CT-D2 | d1*L2*SD3.175*L*α | 0.4-≤0.8 | 4~13.5 | 20 | 3.175 | 38/45 | 110°-130° | Alumina ceramics, zirconia ceramics and other composite ceramic wear-resistant materials Quartz, microcrystalline glass, sapphire and other non-metallic materials |

| 0.8-≤2.0 | 3.175 | 38/45 | 110°-130° | |||||

| MSH-CT-D3 | d1*L2*SD3.175*L*α | 0.2-≤0.35 | 2~4 | 38 | 3.175 | 38/45 | 110°-130° | Monocrystalline silicon,polysilicon |

| 0.35-≤0.75 | 2~7 | |||||||

| 7~13.5 | ||||||||

| Non-standard products can be customized! | ||||||||

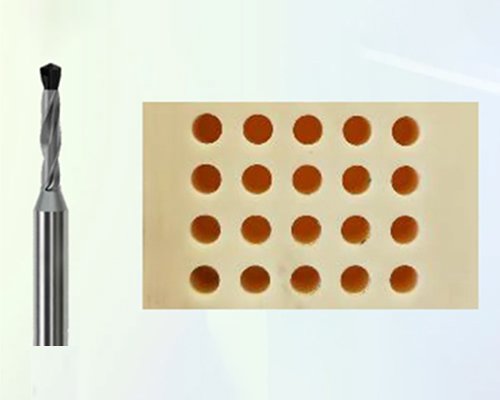

Alumina ceramic processing difficulties

1.High hardness: Alumina ceramics have high hardness and can easily lead to serious tool wear. High-hardness PCD tools need to be used to meet this challenge.

2.Prone to cracks: Alumina ceramics are prone to cracks and have high requirements for the stability of the cutting process and the control of cutting forces. Reasonable cutting parameters are required to avoid the formation of cracks.

3.Slow heat dissipation: Alumina ceramics have poor thermal conductivity and are prone to high temperatures during processing. Effective cooling measures are required to maintain processing stability.

| Rotation | S3000 |

| Feed speed | F10 |

| Processing depth | 10mm |

| Processing advantages | Efficient processing

Precision processing Longer service life |

Silicon carbide ceramic processing difficulties

1. Extremely high hardness: Silicon carbide has extremely high hardness and wear resistance, which places extremely high requirements on the wear resistance and cutting stability of the tool.

2. It is prone to thermal cracks: Silicon carbide is prone to heat during processing, causing the surface temperature to rise, which in turn causes thermal cracks. Cutting parameters and heat dissipation need to be controlled to avoid this problem;

3. Easy to produce fragments: Silicon carbide is prone to produce chips and particles during processing, which increases the risk of tool wear and surface roughness.

![]()

| Rotation | S8500 |

| Feed speed | F2.5 |

| Processing depth | 4mm |

| Processing advantages | Strong wear resistance

Efficient processing Excellent surface quality

|