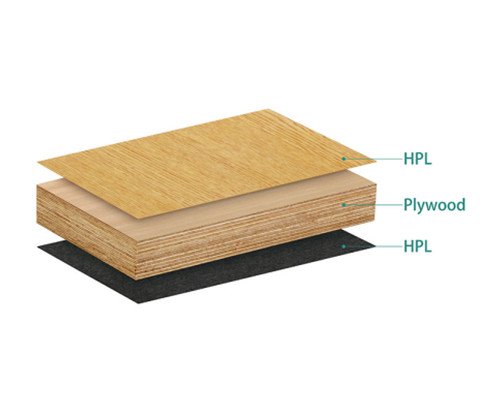

HPL stands for High Pressure Laminate, which is a type of composite material made from layers of kraft paper impregnated with phenolic resin, bonded under high pressure and temperature. The resulting material is a durable, non-porous, and resistant to heat, scratches, and impact.

Durability: anti-wear, anti-scratch, heat-resistant, and chemical corrosion-resistant.

Moisture resistance: The surface is not easy to absorb water and is suitable for humid environments.

Environmental protection: Some brands of HPL boards meet the requirements of low formaldehyde emissions.

Decorative: There are many colors, textures, matte or high-gloss surfaces to choose from.

Easy to clean: The surface is smooth and not easy to stain.

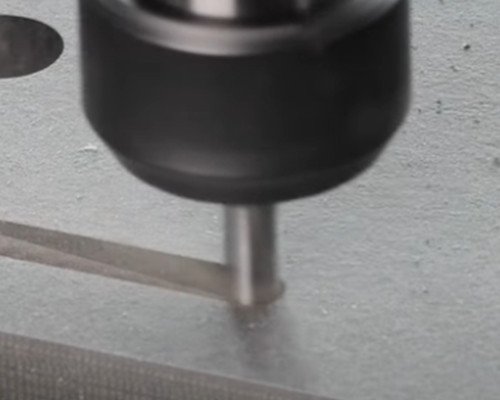

When processing High-Pressure Laminate (HPL), PCD (polycrystalline diamond) tools are often used to ensure tool life and processing efficiency due to its high hardness and wear resistance.

1. PCD milling cutter

Application: Used for trimming, grooving or complex contour processing.

Type:

Straight slot milling cutter: Suitable for simple straight line trimming.

Spiral milling cutter: Suitable for processing complex curved surfaces with high surface requirements, reducing burrs and processing defects.

Features: Smooth cutting, smooth chip removal, and smooth processing edges.

2. PCD drill bit

Application: Used for processing positioning holes or through holes in HPL boards.

Features: High-precision processing of hole diameters and reducing hole edge cracking.

Moresuperhard provide PCD cutting tools according to your drawing and machining requirements.Please contact us freely for quotation.

Cutting bits material: diamond

Cutting body material:carbide

Size: 9.3x15x10x70mm

Workpiece name: HPL(High-pressure Laminate)

Cutting bits characteristics: One edge over the center end mill

Advantage: Good chip removal effect, good processing quality and long working life.