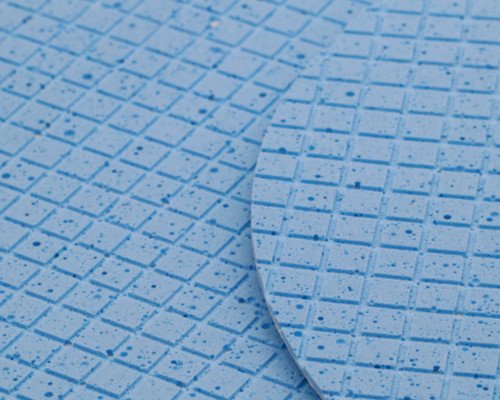

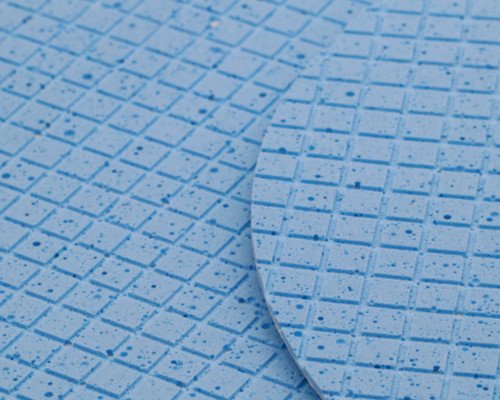

In the manufacturing process of optical lenses, the polishing process is a key step that determines the surface quality. PU (polyurethane) polishing pads, with their unique physical and chemical properties, are widely used in various precision polishing applications, ensuring high efficiency and stable performance in optical processing.

The PU polishing pad is made from specially foamed micro-porous rigid plastic elastomer. Based on the type of abrasive filled, it is classified as:

| Shape | Dimensions |

|---|---|

| Rectangle | 1397 × 584 mm 1400 × 640 mm 1400 × 700 mm 1500 × 750 mm 1700 × 850 mm 1800 × 900 mm |

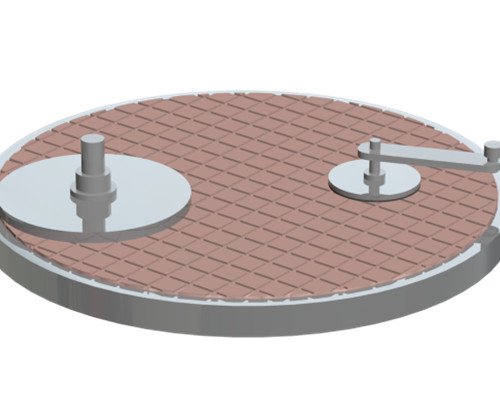

| Circular | Φ380 mm Φ640 mm Φ960 mm Φ1050 mm Φ1200 mm Φ1300 mm Φ1350 mm |

| Thickness | 0.5 mm / 0.8 mm / 1.0 mm / 1.27 mm / 1.5 mm / 2.0 mm / 2.5 mm / 3.0 mm |

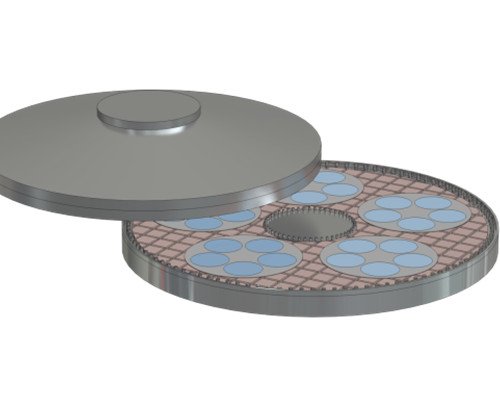

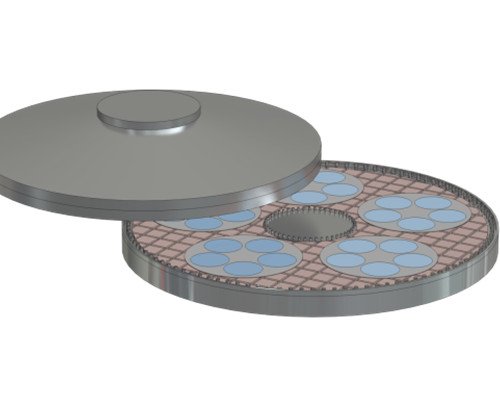

Used for surface thinning and polishing of materials such as:

We provide customized solutions to meet diverse customer needs, including:

With the increasing demands for ultra-precision in optical manufacturing, polishing technology is evolving toward greater specialization. Proper selection and standardized use of polishing pads can significantly improve product yield and processing efficiency.