· Reduce eccentricity

After the blade is installed, there is an offset between the center of the blade and the center of the spindle, resulting in eccentricity, which is not a true circle during high-speed rotation.

· Increase diamond cutting blades sharpness

The diamond of the new knife is not exposed and the cutting ability is poor. After sharpening, the diamond is fully exposed and can create chip grooves to increase chip evacuation capacity.

· Improve dresser board sharpening efficiency

Pre-cutting using a trimming board can be completed in a short time, which greatly reduces the sharpening time and obtains good processing quality in a short time.

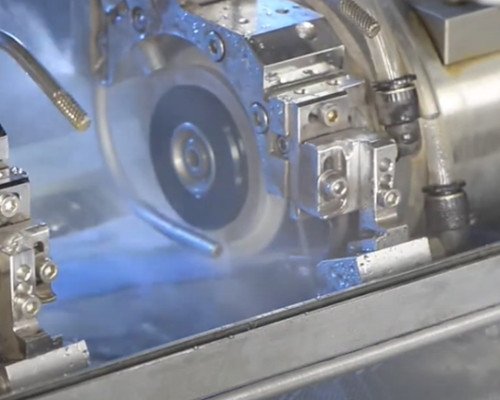

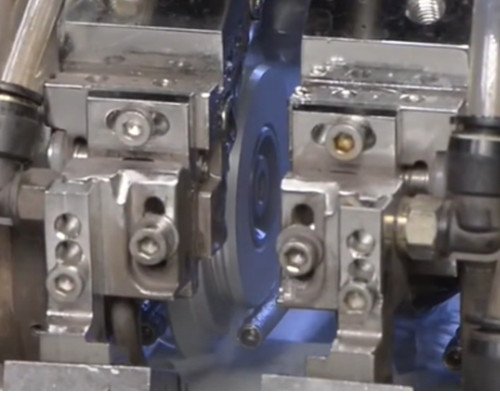

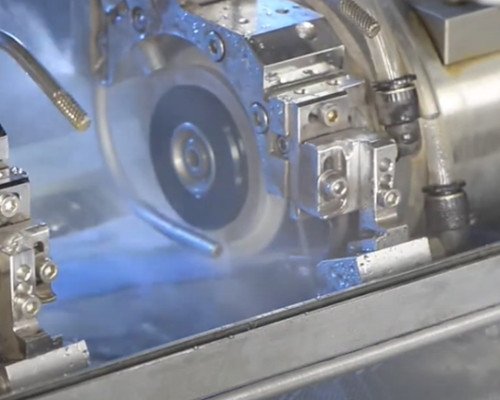

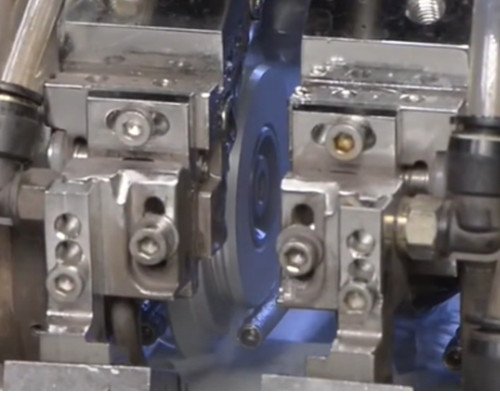

The dressing effect of the precut board

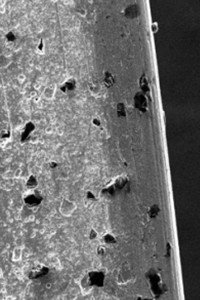

Diamond dicing blades before dressing

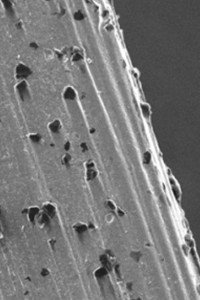

diamond dicing blades after dressing

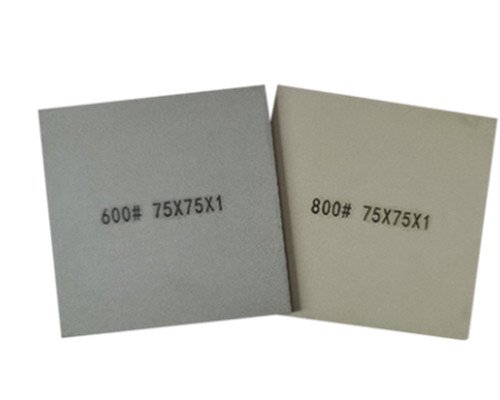

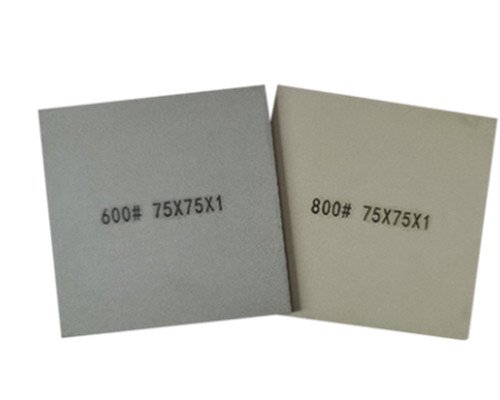

| Abrasive grain sizes | Abrasives particle concentration | Sizes(mm) | Thickness(mm) |

| 320# | 50 | 75*75 | 1 |

| 400# | 50 | 75*75 | 1 |

| 600# | 50 | 75*75 | 1 |

| 800# | 50 | 75*75 | 1 |

| 1000# | 50 | 75*75 | 1 |

| 2000# | 50 | 75*75 | 1 |

| 3000# | 50 | 75*75 | 1 |

| 4000# | 50 | 75*75 | 1 |

| 5000# | 50 | 75*75 | 1 |

Dressing case of resin dresser board

| Dresser board type | Resin bond dresser board |

| Dressing board grain sizes | 400# |

| Dressing dicing blades speed(rpm) | 17000 |

| Dressing feed(mm/s) | 6 |

| Dressing depth(mm) | 0.5 |

| Dressing number | 5 |

| Dressing time | 1 min |

| Burr size | <10㎛ |

| Chpping sizes | <5㎛ |