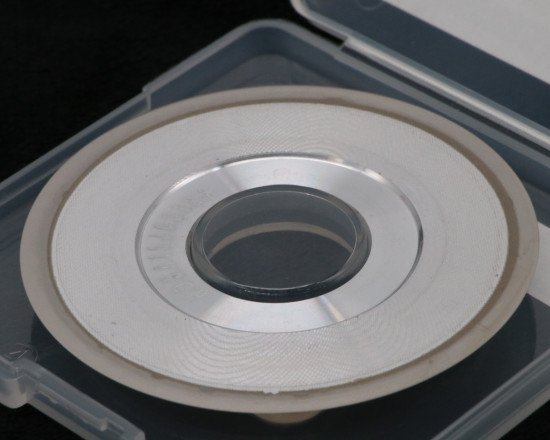

1. Resin diamond scribing blades have good elasticity and can maximize cutting capabilities

2. High precision, sharp cutting, good self-sharpening, and fast particle renewal, effectively ensuring the good cutting status of the blade

3. According to different processing materials, different cutting tools can be customized and designed, and the cutting edge can also be grooved to meet different processing needs

4. The blade can be adapted to the mainstream dicing machines in the market and is an important tool for semiconductor cutting

![]()

Moresuperhard resin diamond dicing blade help you solve cutting problems

1. Diamond dicing blade life

2. Collapse problem

3. Cutting and layering

4. There are burrs on the edge of the product

Semiconductor: BGA cutting, PCB board cutting, QFN cutting, DFN cutting

Optical glass: optical glass, quartz glass, etc.

Metal materials: micro drills, milling cutter rods, rare earth magnetic materials, etc.

Cutting ceramics: silicon carbide, zirconia, etc.

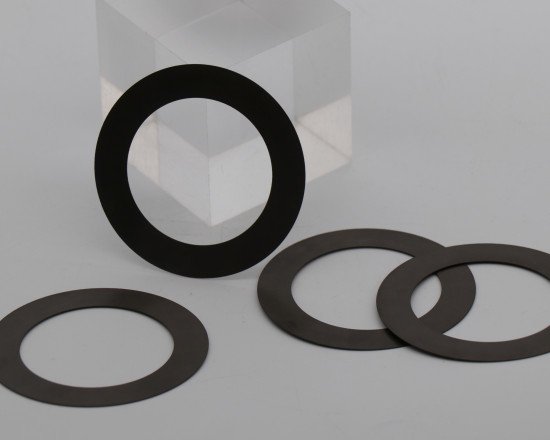

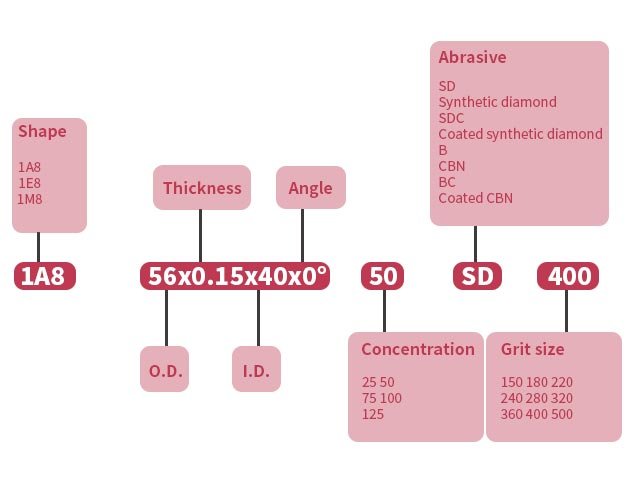

Resin bond diamond dicing blade specifications

Customer Case: Resin Diamond Dicing Blades for QFN Package Sawing

| Parameter | Details |

| Application | QFN (Quad Flat Non-leaded) package sawing |

| Blade Size | D58 × H40 × 0.3mm |

| Grit Size | 240# |

| UV Tape Thickness | 0.17mm |

| Cutting Water Temperature | ~22°C |

| Package Thickness | 0.75mm & 0.9mm |

| Leadframe Supplier | Mainly from QPL, China (Half-etch leadframes) |

| Material Types | – Copper frames with Tin plating – NiPdAu Pre-plated leadframes |

Optimization Highlights:

1.Optimized for different package thicknesses to reduce chipping and burrs.

2.Maintains sharpness and cutting efficiency at 22°C water temperature.

3.Compatible with various QFN leadframe materials for high adaptability.