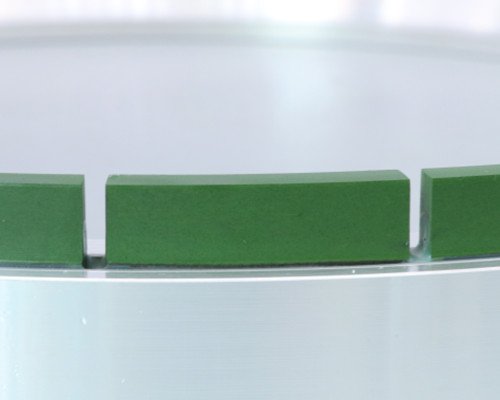

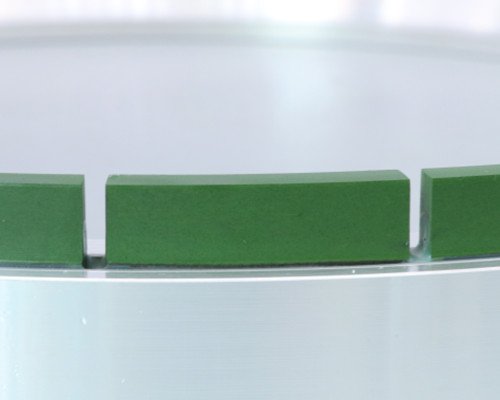

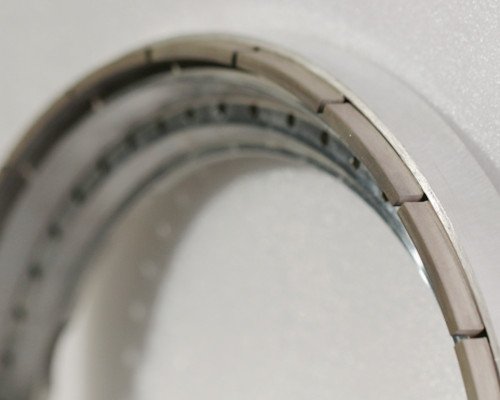

• Excellent self-sharpening and elasticity

• High processing efficiency and low processing temperature

• High machining accuracy and surface quality

•Superior finishing quality

•Long-life specification – high wear resistance

•Large product range – able to process compound semiconductor wafers and crystal materials

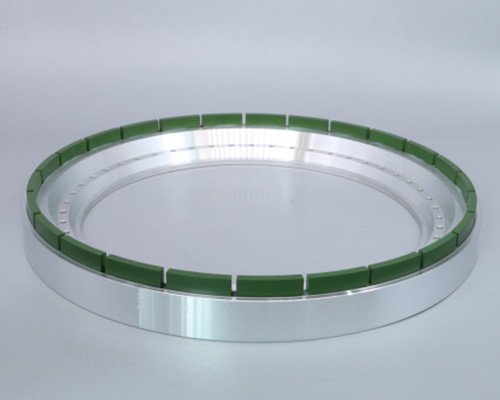

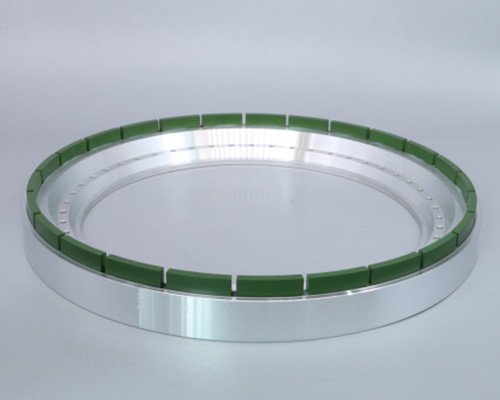

Applications of Resin bond diamond back grinding wheel

Silicon wafer, sapphire, gallium nitride, gallium arsenide

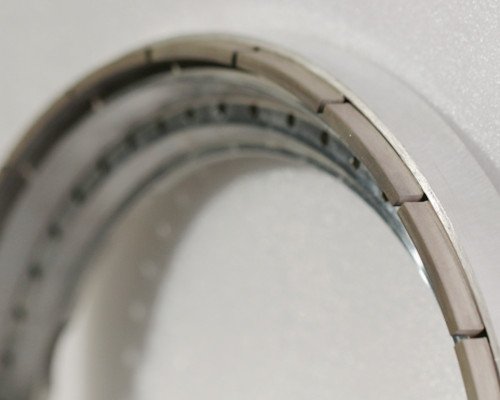

| Model | D (mm) | T (mm) | H (mm) |

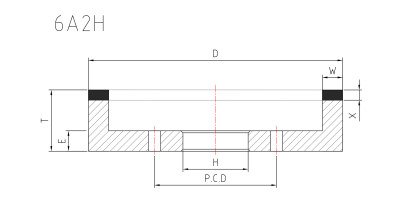

6A2/6A2H |

175 | 30, 35 | 76 |

| 200 | 35 | 76 | |

| 350 | 45 | 127 | |

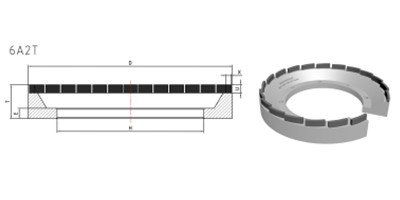

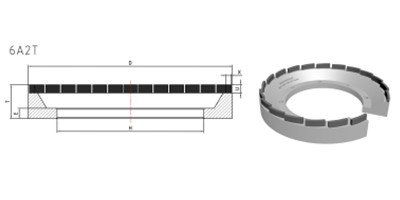

6A2T |

195 | 22.5, 25 | 170 |

| 280 | 30 | 228.6 | |

6A2T(three ellipses) |

350 | 35 | 235 |

| 209 | 22.5 | 158 | |

| Other specifications can be produced according to customers’ requirement. | |||