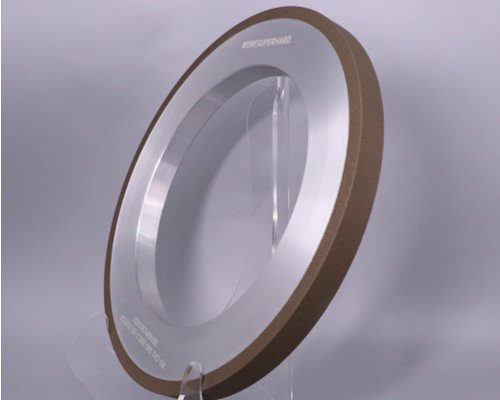

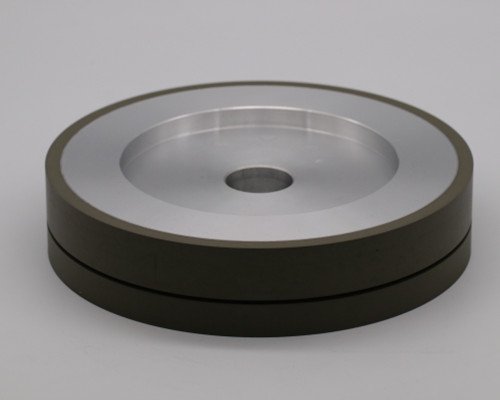

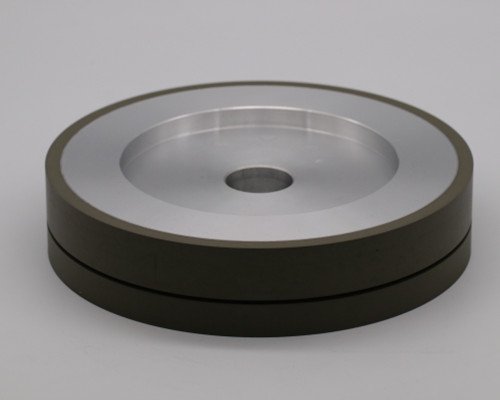

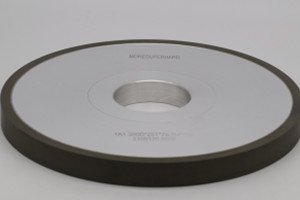

Resin diamond grinding wheel is a kind of efficient and durable grinding tool, which is made of diamond abrasive and resin bond, and is suitable for processing hard materials such as cemented carbide, ceramics, optical glass, sapphire, semiconductor materials, etc. The resin bond has good elasticity and grinding performance, and is particularly suitable for processes requiring precision grinding or polishing.

1. High hardness and high grinding efficiency

Diamond is the hardest material in nature at present, so the resin diamond grinding wheel can efficiently cut and grind various high-hardness materials in a short time.

2. Good wear resistance

The resin bond has strong wear resistance, which ensures a long life of the grinding wheel during processing, reduces the frequency of replacement, and improves production efficiency.

3. High grinding accuracy

The resin diamond grinding wheel has good self-sharpening and elasticity, which can reduce surface damage during processing and achieve high-precision finish, suitable for fine processing and polishing.

4. Low heat generation

The elasticity and self-sharpening of the resin grinding wheel make it generate less heat during the grinding process, which can effectively avoid thermal damage and deformation of the workpiece.

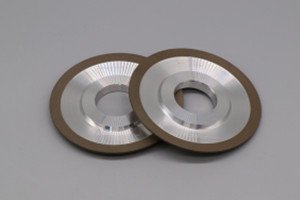

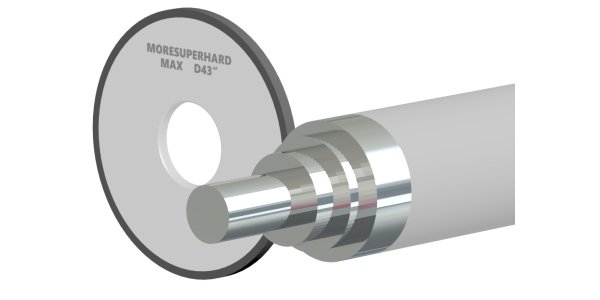

1.Resin diamond grinding wheel for carbide tools

During the forming and grinding process of carbide tools, resin diamond grinding wheels show excellent grinding performance, which can achieve precise processing and sharp cutting edges.

2. Resin diamond wheel for processing ceramic material

When processing brittle ceramic materials, resin diamond grinding wheels can reduce the edge collapse and cracks of materials, ensuring the high surface quality of the processed products.like Alumina ceramics, zirconia ceramics,Silicon nitride (Si₃N₄) ceramics, silicon carbide (SiC) ceramics, boron nitride ceramics (BN),Barium titanate (BaTiO₃) ceramics, lead zirconate titanate (PZT) ceramics etc.

3. Resin bond diamond grinding wheel for processing optical glass and sapphire

Resin diamond grinding wheels are often used for grinding and polishing of precision optical lenses and sapphire windows, and can achieve very high finish and precision.

4. Semiconductor material processing

When processing semiconductor materials such as silicon wafers and sapphire, resin diamond grinding wheels can efficiently remove materials while ensuring the shape accuracy and surface quality of the workpiece.like Si, SiC,GaAs,GaN,ZnO etc.

![]()

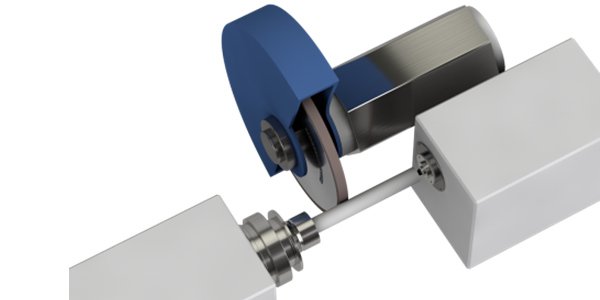

5.Resin diamond wheel for thermal spraying industry

Resin diamond external cylindrical grinding wheels are used for grinding and polishing of difficult-to-grind materials such as thermal spray coatings (tungsten carbide, chromium carbide, chromium oxide), ceramics, carbides, and chilled iron composites.

6.Resin diamond grinding disc for polishing gem

Resin diamond gem grinding discs have the characteristics of high cutting force, good polishing effect, excellent self-sharpening and low heat generation. They are suitable for fine grinding and polishing of gemstones such as diamond, jade, ruby, sapphire, etc.

|

Specifications |

|

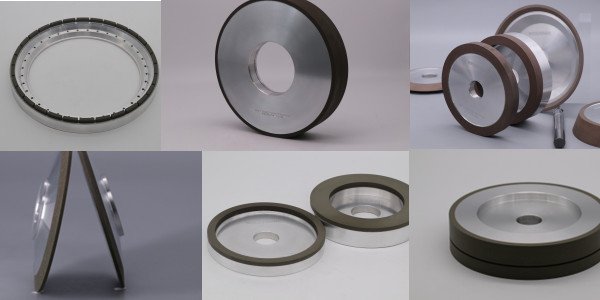

| Diameter | 50mm – 1000mm |

| Thickness | 3mm – 50mm |

| Hole | 10mm – 127mm |

| Grit Sizes | 60# – 4000# |

| Bond | Resin bond |

| Speed | 25m/s – 60m/s |

| Grinding Method | Dry grinding or grinding with collant |

Resin diamond grinding wheels have become an indispensable tool for processing high-hardness materials due to their efficient grinding performance, wide range of applications and excellent wear resistance. Moresuperhard provides standard and customized resin diamond grinding wheels for processing various hard and brittle materials. Factory production, fast delivery, stable products and high grinding efficiency.