Clasfications of advanced ceramic

According to chemical composition, they can be divided into oxide ceramics, nitride ceramics, carbide ceramics, boride ceramics, silicide ceramics, fluoride ceramics, sulfide ceramics, etc.

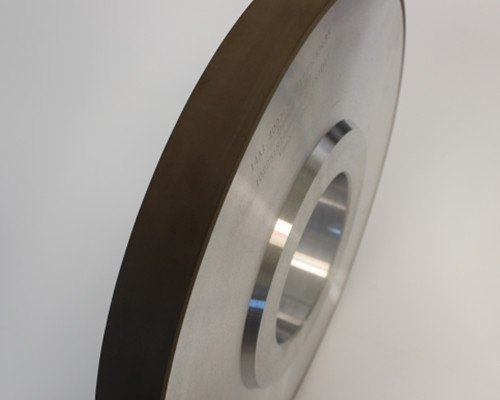

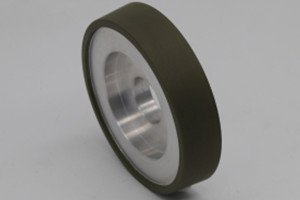

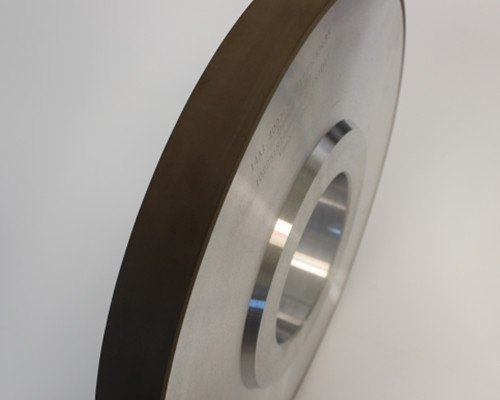

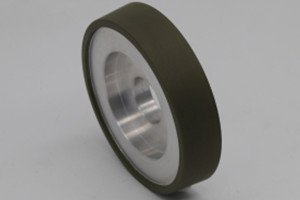

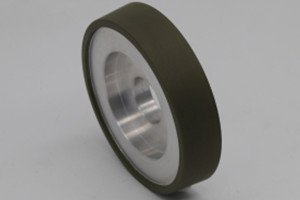

Resin diamond surface grinding wheel for ceramic materials

Specifications of external grinding wheel

| Type | Diameter(inches) | D(mm) | H(mm) | X(mm) | T(mm) | U(mm) |

| 1A1 | 4”

|

100 | 20 | 6 | 12 | |

| 1A1 | 100 | 20 | 10 | 10 | ||

| 1A1 | 100 | 20 | 10 | 12 | ||

| 1A1 | 100 | 25.4 | 10 | 20 | ||

| 1A1 | 8” | 200 | 76.2 | 10 | 25 | |

| 1A1 | 12”

|

300 | 76.2 | 10 | 25 | |

| 1A1 | 300 | 127 | 10 | 25,30,40 | ||

| 1A1 | 300 | 127 | 25 | 50 | ||

| 14A1 | 300 | 127 | 6,10 | 40 | 10 | |

| 14A1 | 300 | 127 | 10 | 40 | 15 | |

| 1A1 | 16”

|

400 | 127 | 10,25 | 25 | |

| 1A1 | 400 | 127 | 10 | 30,40,50 | ||

| 1A1 | 20”

|

500 | 203 | 10 | 15,20 | |

| 1A1 | 500 | 254 | 38 | 25,50 | ||

| 1A1 | 24”

|

600 | 254 | 25 | 25 | |

| 1A1 | 600 | 304.8 | 5 | 40 | ||

| 1A1 | 600 | 203 | 25 | 50 | ||

| 1A1 | 600 | 304.8 | 10 | 50 | ||

| 1A1 | 30” | 750 | 304.8 | 10 | 40,50 | |

| 1A1 | 35.4” | 900 | 304.8,305 | 10 | 50,75 | |

| 1A1 | 36” | 914.4 | 304.8,305 | 10 | 50.8 | |

| 1A1 | 43” | 1100 | 304.8 | 10 | 50 | |

| We can also customized according to your requirements. | ||||||

Why choose Moresuperhard resin external grinding wheel?

Excellent surface quality: Moresuperhard’s resin bond diamond grinding wheel has good elasticity, which can reduce vibration and heat accumulation during grinding, and provide high surface finish and precision.

Low workpiece breakage rate: Because the resin bond has a certain buffering effect, it can effectively reduce the impact of grinding force on the workpiece and reduce the breakage rate of ceramic materials.

High material removal rate: The combination of the high hardness of diamond and the flexibility of resin bond enables the grinding process to quickly remove material while maintaining good workpiece surface quality.

Long life and economy: Moresuperhard diamond grinding wheels have a long service life, which can reduce the cost and downtime of frequent tool changes, thereby improving production efficiency and economic benefits.