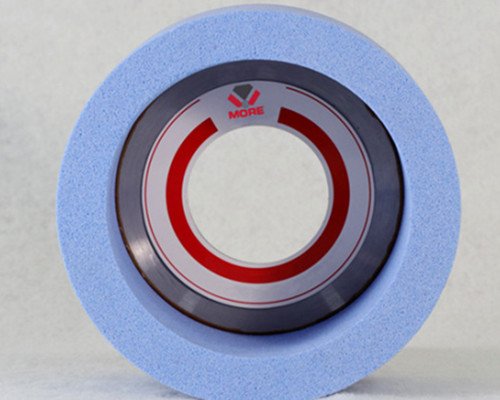

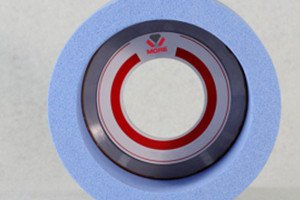

SG grinding wheel (Seeded Gel abrasive grinding wheel) is a high-performance grinding wheel made of advanced ceramic aluminum oxide abrasive. It has excellent grinding performance and self-sharpening, so it performs well in the processing of many high-hardness materials.

Characteristics of SG grinding wheel

High hardness and high wear resistance: The abrasive of SG grinding wheel is very hard and can effectively grind high-hardness materials.

Self-sharpening: During the grinding process, the abrasive of SG grinding wheel will continuously expose new sharp edges, thereby maintaining efficient cutting performance and reducing grinding wheel clogging and wear.

Low heat generation: SG grinding wheel design can generate less heat during the grinding process, thereby reducing burns and thermal deformation on the workpiece surface.

Specifications of SG grinding wheel

internal grinding,external grinding ,form grinding,gear grinding etc.

Customized specifications and sizes SG grinding wheel for your workpieces.

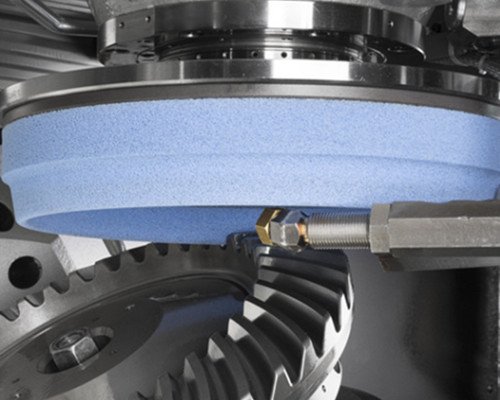

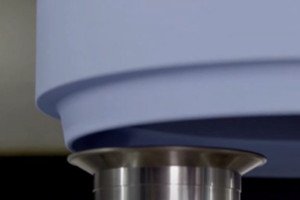

Application of SG grinding wheel

► Precision grinding of unhardened and hardened steel, such as cast iron, carbon steel, alloy steel, tool steel, etc.

► Internal grinding of roller bearings, cylinders, compressor parts, gear parts, hydraulic and pneumatic cylinders, etc.

► Grinding of engine crankshafts, camshafts and automobile transmissions, grinding of worm gears

Dressing solutions for SG grinding wheel

Diamond rollers are suitable for mass production and high-precision dressing, while diamond dressing pens are more suitable for small batches, diversified production and flexible dressing needs. Choosing the right dressing tool depends on the specific processing requirements, production scale and budget. By rationally selecting and correctly using dressing tools, the service life of SG grinding wheels can be effectively extended and their efficient and high-precision grinding performance can be maintained.

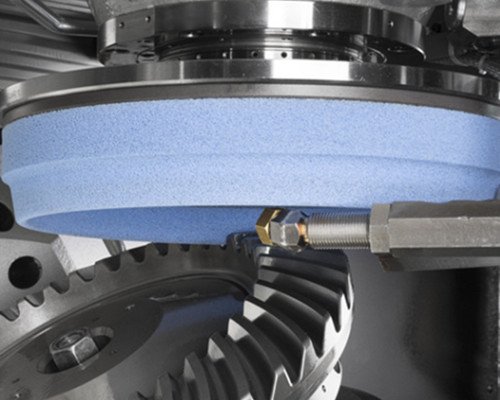

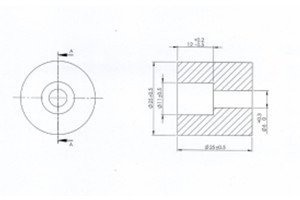

Project Requirements

The customer needs an efficient and durable grinding wheel to grind carburized steel 20CrMnTiH. The grinding wheel is required to reduce heat generation while maintaining high hardness and wear resistance, avoid burns on the workpiece surface, and ensure that the depth of the carburized layer after grinding meets the design requirements.

Solution

After detailed analysis and technical evaluation, it is recommended that customers use SG general grinding wheels with the following specifications:

Size: D25xT25xH6xP11xF12mm

Grit: 80#

Hardness: HRC 58-63

Heat treatment: carburizing heat treatment

Effective carburizing layer depth: 1.2-1.6mm before grinding, 1.0-1.4mm after grinding

Customer feedback

Customers are very satisfied with the performance of SG grinding wheels, especially the high efficiency, stability and durability when grinding carburized steel 20CrMnTiH. By using SG grinding wheels, customers not only improve product quality, but also significantly improve production efficiency and reduce processing costs.