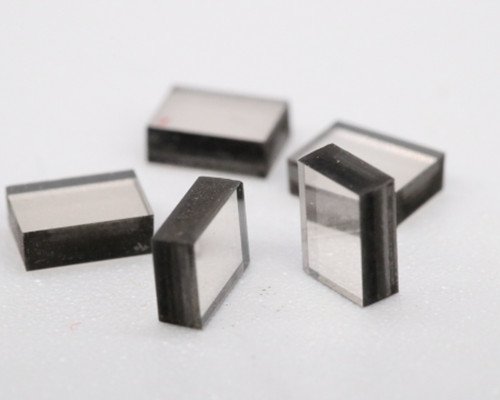

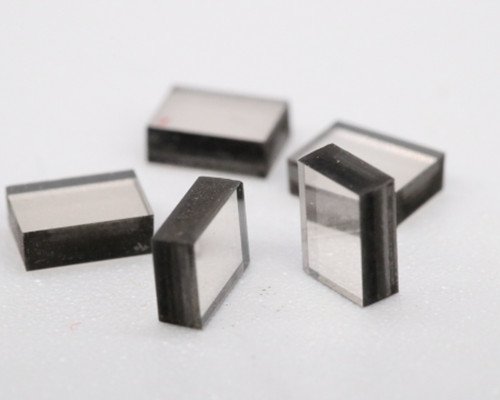

The uniform crystal structure of single crystal diamond without internal grain boundaries makes the cutting edge of the tool theoretically reach atomic-level straightness and sharpness. It has strong thinning ability, high precision and low cutting force during cutting; The cutting edge is extremely small, the cutting edge is free of defects, the machined surface can achieve a mirror effect, and its surface roughness can reach below Ra-0.1μm.

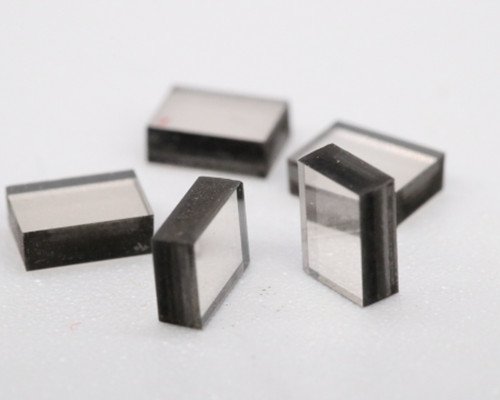

Moresuperhard provide MCD/CVD diamond plate for single crystal cutting tools

CVD single crystal diamond tool product introduction:

Tool-grade single crystal diamond has excellent machining performance: high hardness, long life, high wear resistance!

Size: 1-12mm

Nitrogen content: 50-100 ppm

Young’s modulus: 1150~1300 GPa

Microhardness: 80~150 GPa

Orientation: Normal (6 sides 100), special (up and down 100, four sides 110), custom 2pt (up and down 110)

CVD single crystal diamond products are now widely used in precision tools for processing non-ferrous metals such as gold, silver, copper, aluminum, and hard, brittle and difficult-to-machine materials such as graphite, carbon fiber, and ceramics, and can be customized according to customer requirements. Help solve customers’ professional problems such as chipping, difficult grinding, welding cracks, etc.!

MCD HPHT single crystal diamond plate

Diamond Grinding wheel for grinding single crystal diamond tools and how to use

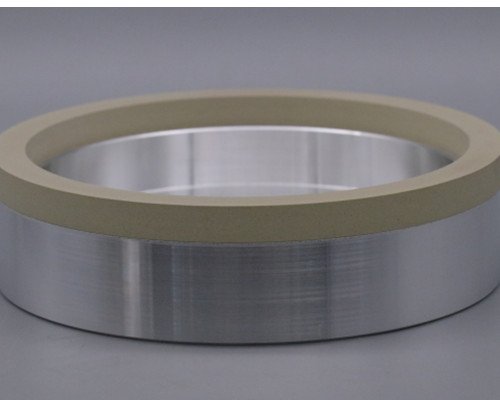

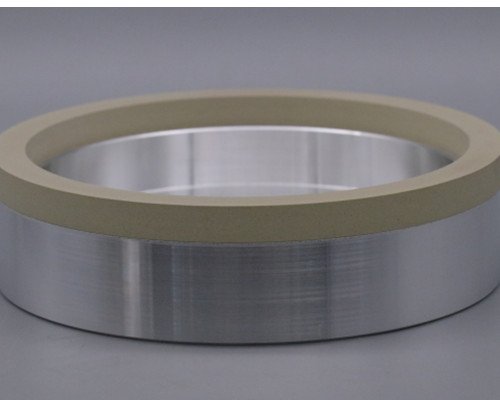

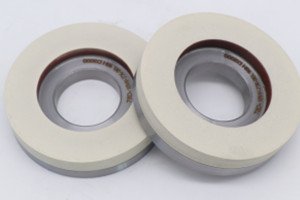

Vitrified diamond grinding wheel and metal bond diamond grinding wheel for grinding single crystal diamond tools

Coarse and fine grinding wheels have been successfully matched with COBORN PG3 and RG9A, EWAG-RS15, FC-200D, M50CNC ,MT-188, MT198NC and other high-end diamond tool grinders.The grain size ranges from coarse grinding W40 to ultra-fine grinding 10000#. Coarse grinding: W40, W20 Semi-fine grinding: W10, W5 Fine grinding: W3.5, W2.5, W1.5

Moresuperhard provide diamond grinding wheel for Coborn pg single crystal diamond grinding machine .

Grinding Machine for single crytal diamond tools

The structure is compact, the operation is simple, and it has the functions of constant pressure feed, rapid advance and retreat, vertical axis pneumatic brake, etc., which can effectively improve the processing efficiency and processing quality. The machine tool adopts the structure of servo motor, ball screw and high-strength rolling guide rail to drag the grinding wheel spindle to move, and the position, swing amplitude and swing frequency of the grinding wheel spindle can be adjusted online. The spindle stroke of the grinding wheel of the machine tool is 280mm, the swing frequency is 0-40 times/min, the stroke of the tool carriage is 70mm, and the spindle speed is 0-4200 rpm.

How to grinding single crystal diamond tools?

Single crystal diamond tool sharpening method:Moresuperhard W40 vitrified diamond grinding wheel on M50 cnc grinding machine for rough grinding . Or directly use W20 for rough grinding to ensure controllable cutting edge and improve service life, which can greatly improve the grinding efficiency; Then use W10 for fine grinding, the cutting edge can reach 0.01mm-0.013mm(magnification 200 times), fully meet the semi-finishing requirements of most customers, and the grinding force has also been greatly improved, and then use ceramic bond diamond grinding wheel or metal bond diamond grinding wheel according to the fine grinding requirements.