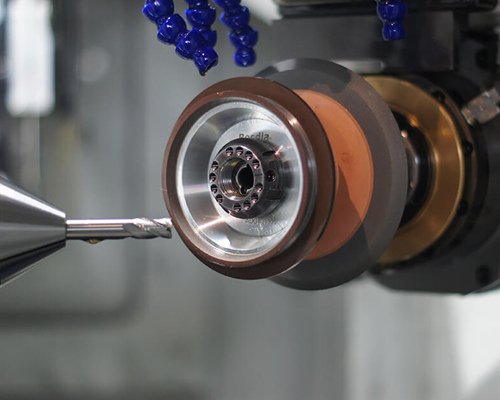

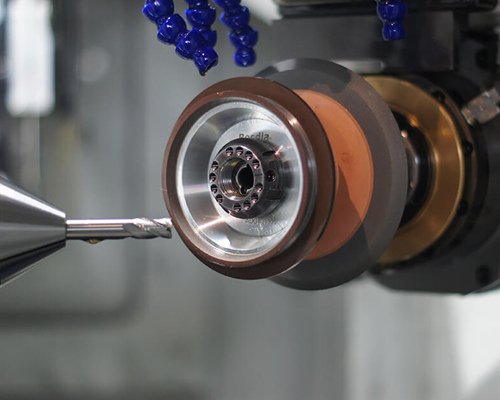

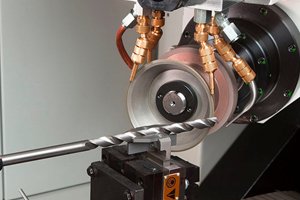

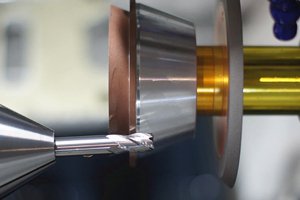

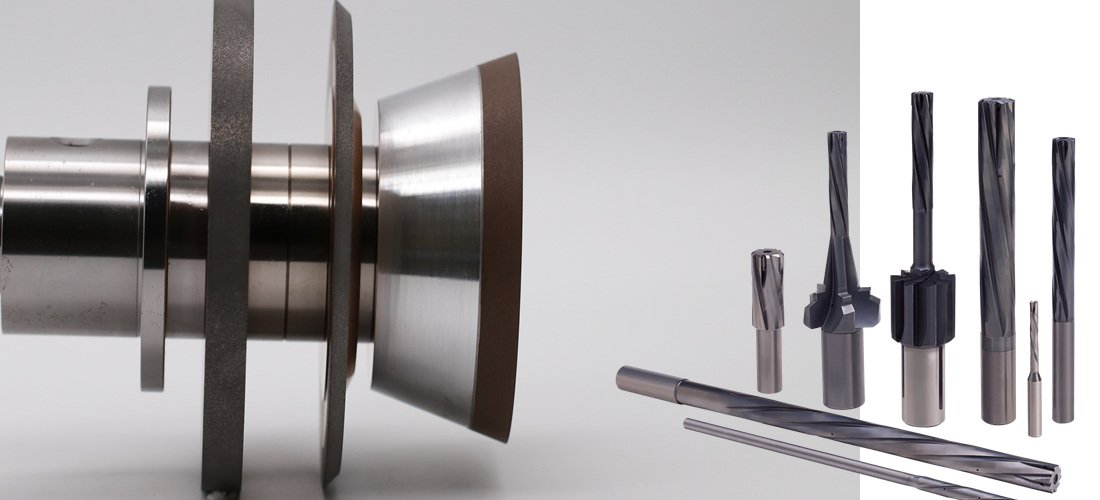

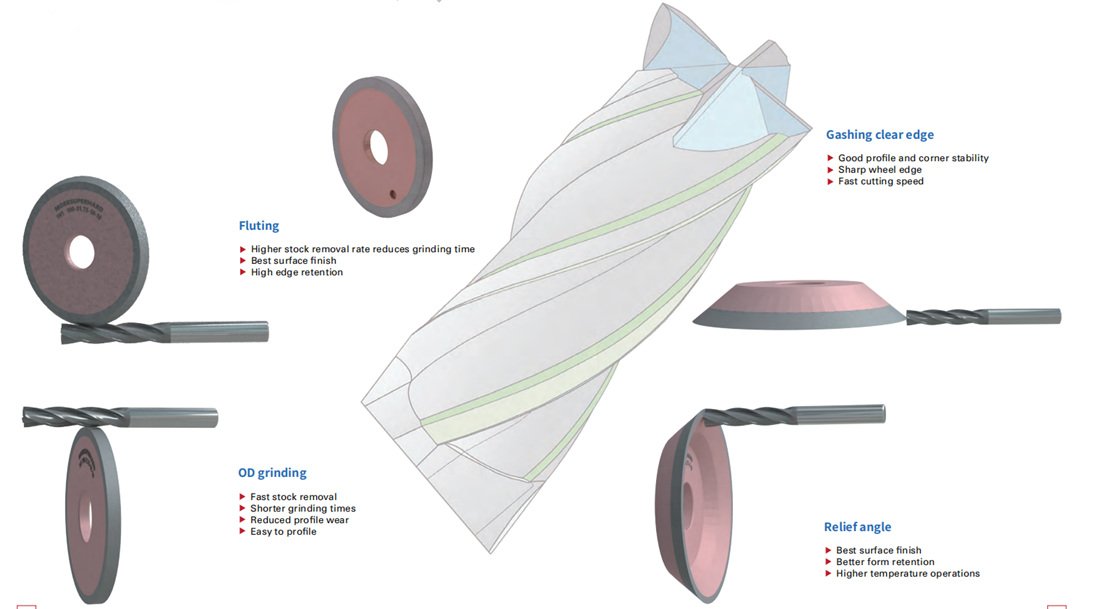

Moresuperhard Diamond and CBN grinding wheels are engineered for CNC tool grinders—perfectly matched to tungsten carbide, high-speed steel (HSS), stainless drills, end mills, and reamers. Utilizing mature bond formulations for superior accuracy, longer wheel life, and fast global delivery.

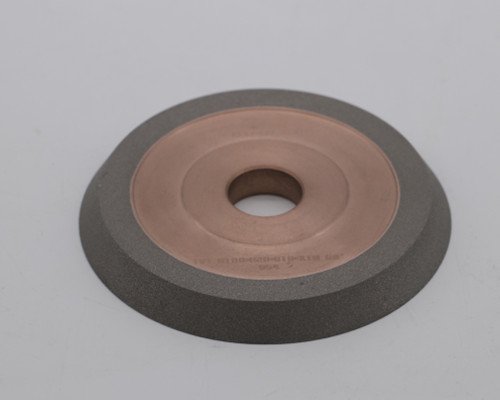

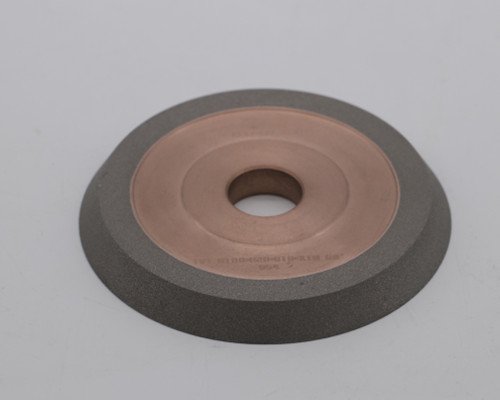

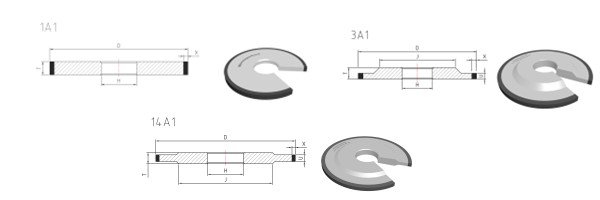

– 1A1/ 14A1/3A1 (Flute grinding, Relif grinding, OD grinding)

| Type | D | T/U | X | V | Grit Size | ||||

|

1A1 14A1 3A1 |

mm | Inch | mm | Inch | mm | Inch | diamond | CBN | |

| 75 | 3 | 1-12 | 1/25-1/2 | 3-10 | 1/8-2/5 |

90̊ |

D64 D54 D46 | B126 B91 B76 | |

| 100 | 4 | 1-16 | 1/25-2/3 | 3-10 | 1/8-2/5 | ||||

| 125 | 5 | 1-16 | 1/25-2/3 | 6-10 | 1/4-2/5 | polishing | |||

| 150 | 6 | 2-16 | 1/12-2/3 | 6-15 | 1/4-3/5 | D35,D25D20,D15 | B54 B16 | ||

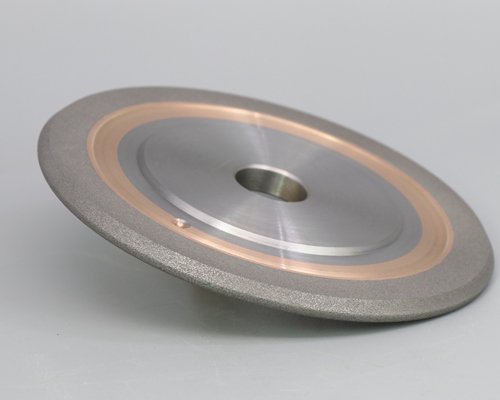

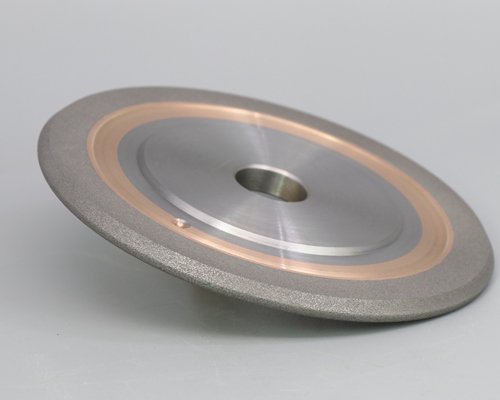

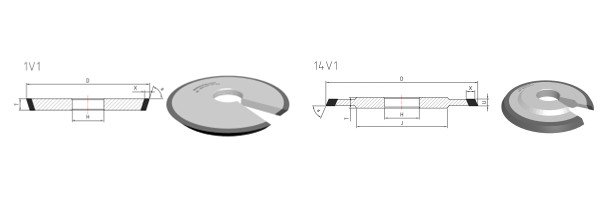

– 1V1/ 14V1 (Flute grinding, Gash grinding)

| Type | D | T | X | V | Grit Size | ||||

|

1V1 14V1

|

mm | Inch | mm | Inch | mm | Inch | diamond | CBN | |

| 75 | 3 | 1-12 | 1/25-1/2 | 3-10 | 1/8-2/5 |

45̊-85̊ |

D64 D54 D46 | B126 B91 B76 | |

| 100 | 4 | 1-16 | 1/25-2/3 | 3-10 | 1/8-2/5 | ||||

| 125 | 5 | 1-16 | 1/25-2/3 | 6-10 | 1/4-2/5 | polishing | |||

| 150 | 6 | 2-16 | 1/12-2/3 | 6-15 | 1/4-3/5 | D35,D25D20,D15 | B54 B16 | ||

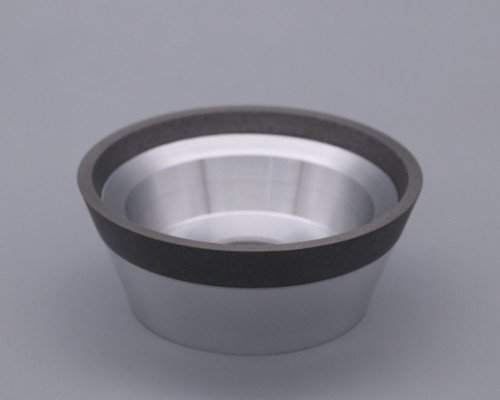

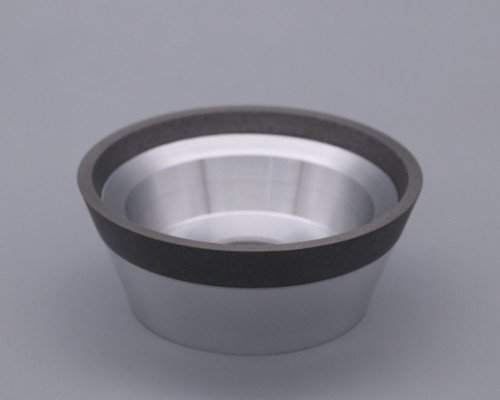

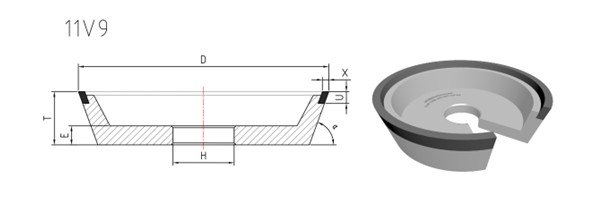

– 11V9 (OD clearence grinding, End face grinding)

| Type | D | T | X | S | Grit Size | ||||

|

11V9 |

mm | Inch | mm | Inch | mm | Inch | diamond | CBN | |

| 75 | 3 | 25-40 | 1-8/5 | 3-10 | 1/8-2/5 |

70̊ 45̊ |

D126 D64 D46 D35 | B126 B91 B76 B64 | |

| 100 | 4 | 25-40 | 1-8/5 | 3-10 | 1/8-2/5 | ||||

| 125 | 5 | 25-40 | 1-8/5 | 3-10 | 1/8-2/5 | ||||

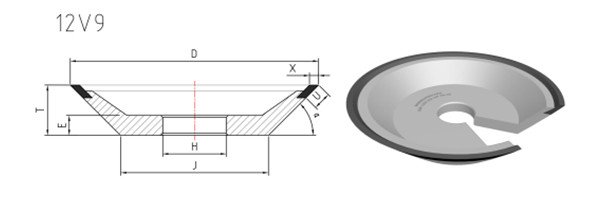

– 12V9 (Relif grinding, Gash grinding, End face grinding)

| Type | D | T | X | S | Grit Size | ||||

|

12V9 |

mm | Inch | mm | Inch | mm | Inch | diamond | CBN | |

| 75 | 3 | 20-30 | 4/5-6/5 | 3-5 | 1/8-1/5 |

45̊ |

D126 D91 D64 D46 D35 | B126 B91 B76 B64 B46 | |

| 100 | 4 | 20-30 | 4/5-6/5 | 3-5 | 1/8-1/5 | ||||

| 125 | 5 | 20-30 | 4/5-6/5 | 3-5 | 1/8-1/5 | ||||

| 150 | 6 | 20-30 | 4/5-6/5 | 3-5 | 1/8-1/5 | ||||

1. Suitable for high-efficiency grinding with fast feed.

2. Good wear resistance and shape retention.

3. Good self-sharpening, less grinding heat, reduced workpiece burns, and meets the high-precision requirements of the tool.

4. No clogging, easy dressing, extended dressing cycle, and reduced processing costs.

5. The quality of the grinding workpiece edge is consistent and the finish is high, which makes the quality stable when processing downstream products.