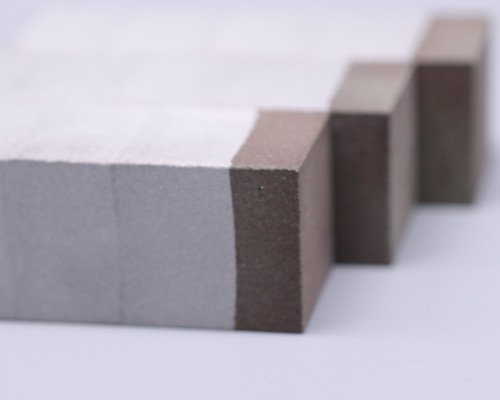

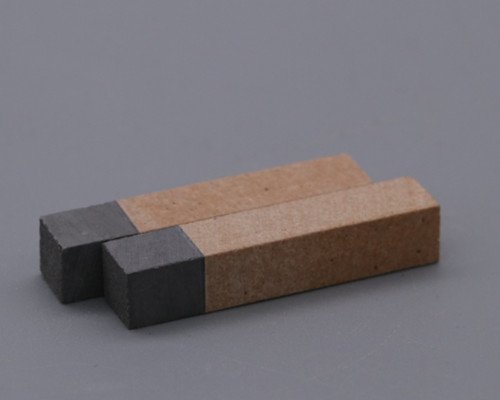

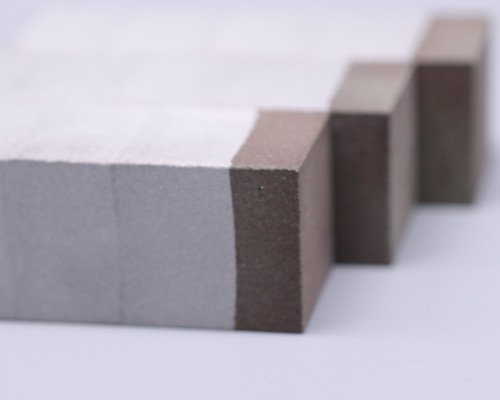

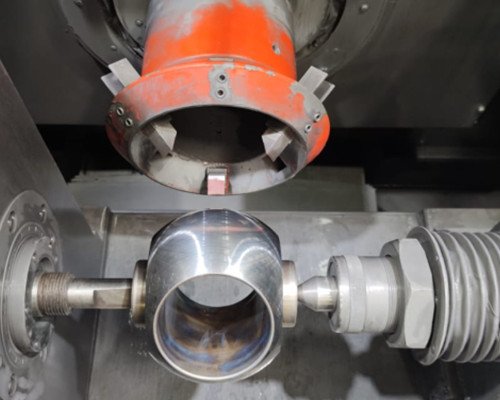

Superfine oilstone is an abrasive product used for superfinishing.Superfine oilstone is suitable for superfine processing of bearings, engine transmission shafts, crankshafts, gears, shock absorbers, connecting rods, piston pins, ball valves and other industry products.Moresuperhard provide oilstone for different materials processing like Gcr15、100Cr6、40Cr、42CrMo、35CrMo、50Mn、 Cr4Mo4V tungsten carbide coating materials etc.

Diamond ,CBN,WA, GC, SC, WA/GC (hybrid abrasive), WA/SC (hybrid abrasive), WA/C (graphite oilstone) etc.

W40、W28、W20、W14、W10、W7、W5、W3.5、W2.5、W1.5

120# 400# 500#、600#、700#、800#、1000#、1200#、1500#、2000#、2500#、3000#、4000#、6000#、8000#、10000#、12000#

Oilstone structure: Use loose structure No. 9~12, and the porosity should be 43%~49%.

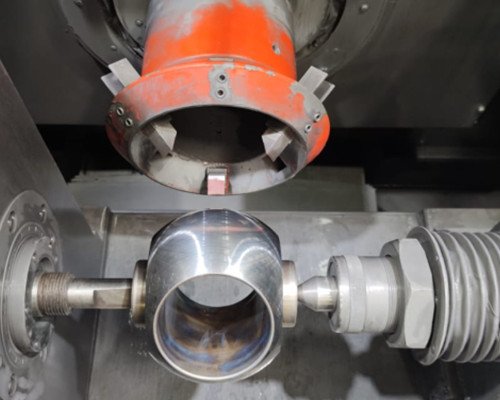

Moresuperhard oil stone suitable machine:THIELENHAUS、Supfina etc

1.Improve surface quality: Super finishing can reduce the surface roughness of the workpiece from Ra=0.2~0.4μm to Ra=0.012~0.050μm, significantly improving the surface quality.

2.Reduce defects: Eliminate defects and deteriorated layers in grinding, extending the service life of the workpiece.

3.Low noise and vibration: The noise and vibration of the processed workpiece are greatly reduced after assembly and operation, and the operation is smooth.

4.High processing efficiency: The processing time is short, only a few seconds to more than ten seconds, and the processing efficiency is dozens of times that of high-precision mirror grinding.

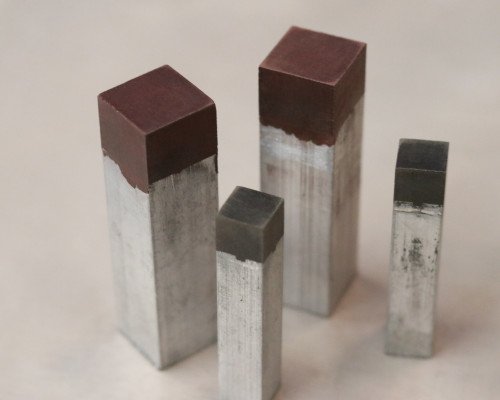

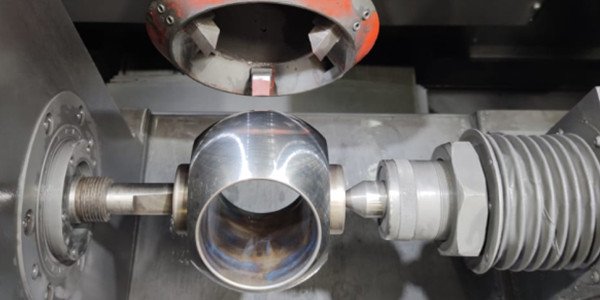

Ball valve grinding oilstone

75x25x25 and other customized sizes

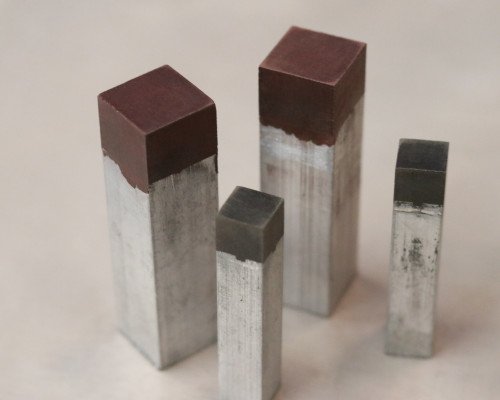

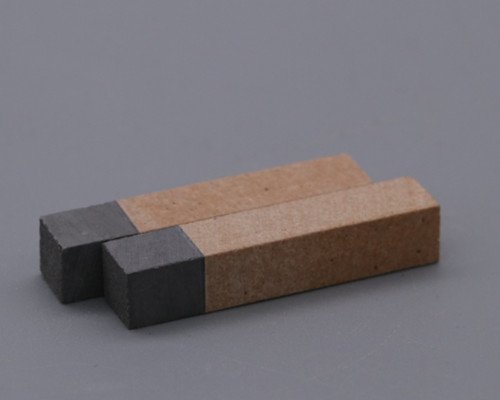

Engine crankshaft polishing oilstone:

18×20×28, 18×20×31, 18×20×33, 18×20×36, 18×20×38, 18×20×40, 18×20×44, 18×20×46, 18×20×48, 26×33×54, 26×36×54, 26×38×54

Gear processing oilstone:

10×20×30, 20×30×50, 18×20×36

Drive shaft processing oilstone:

20×22×25, 20×25×30, 20×22×30