At Moresuperhard, our single crystal diamond (SCD) cutting tools deliver exceptional performance in ultra-precision machining applications. With advanced manufacturing processes and strict quality control, our tools offer the following key advantages:

1.Excellent Surface Finish

Moresuperhard SCD tools produce superior surface quality with ultra-low roughness. The sharp cutting edge and high material purity ensure mirror-like finishes, ideal for optical components, precision lenses, and high-end molds.

2.Long Tool Life

Our single crystal diamond tools are engineered for outstanding wear resistance. Even under continuous machining of hard and brittle materials—such as ceramics, sapphire, glass, and silicon—Moresuperhard tools maintain their cutting performance for extended periods, significantly reducing tool change frequency and production downtime.

3.High Dimensional Accuracy

With minimal wear and excellent edge retention, our SCD tools enable precise control over dimensional tolerances. This ensures high stability in complex and demanding precision manufacturing processes.

4.Efficient Cutting Performance

Moresuperhard SCD tools offer low cutting resistance and excellent heat dissipation, reducing thermal damage to workpieces. They are ideal for micro-cutting and ultra-precision finishing, minimizing sub-surface damage and improving product integrity.

5.Wide Range of Applications

Suitable for machining non-ferrous metals, high-hardness ceramics, semiconductor substrates, and advanced composites, our SCD tools meet the diverse needs of industries such as optics, electronics, aerospace, and medical devices.

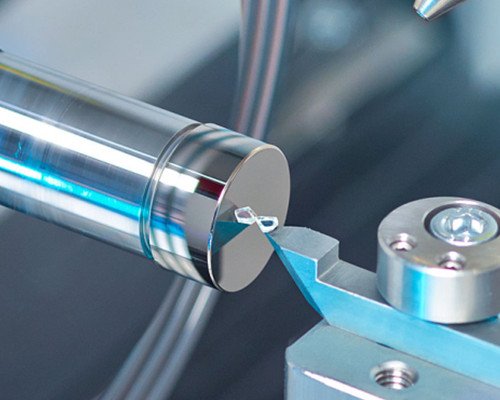

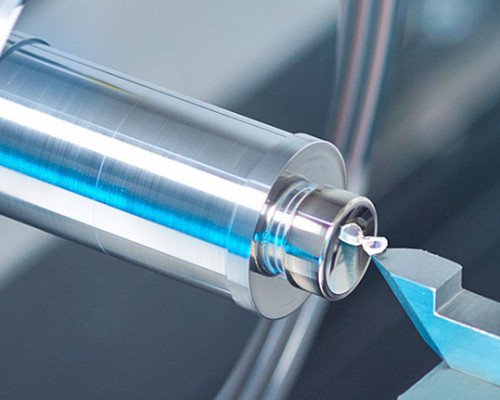

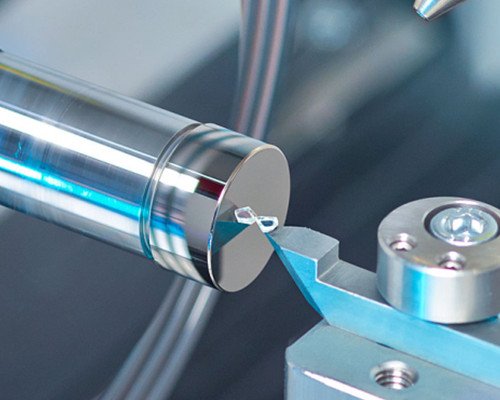

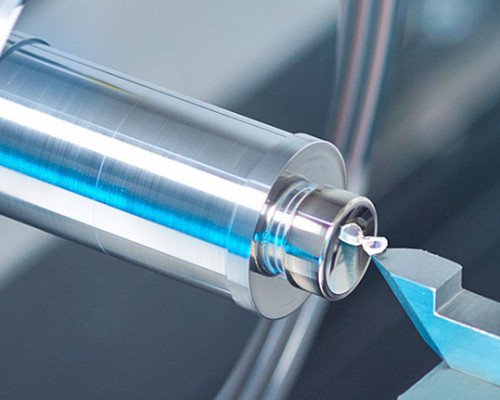

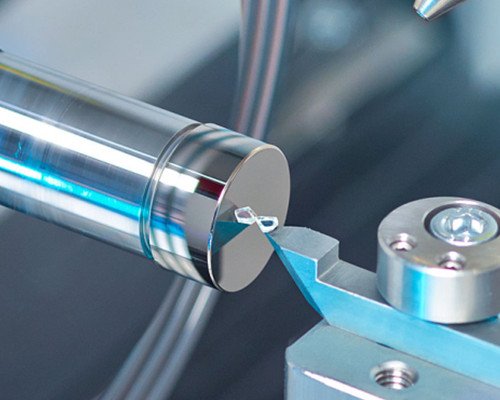

Ultra-precision single crystal diamond arc turning tool is an ultra-precision machining tool, mainly used for machining non-ferrous metals and non-metallic hard and brittle materials, such as nickel, copper, aluminum and other non-ferrous metal materials, as well as germanium wafers, chalcogenide optical glass, silicon wafers and other crystal materials.

Ultra-precision single crystal diamond arc turning tools are widely used in the processing of various infrared lenses, concave and convex lenses, dry diffraction lenses, Fresnel lenses, optical camera lenses, mobile phone camera lenses, sensors and digital devices.

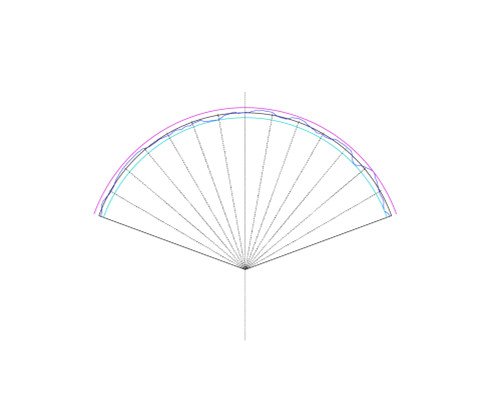

| Item | Specification | ✔ |

| Tool Type | Ultra-Precision Diamond Turning Tool (Arc Tool) | |

| Diamond Type | Natural Diamond | √ |

| Synthetic Diamond | √ | |

| Minimum Radius | 0.001 mm | |

| Maximum Radius | 10.0 mm | |

| Effective Working Angle | 15° – 160° | |

| Included Angle | 20° – 160° | |

| Rake Angle | -45° – +25° | |

| Relief Angle | 0° – 20° | |

| Surface Roughness (Waviness) | 2.0 μm – 30 nm | |

| Tool Holder Type | Solid Shank | √ |

| Insert Type | √ | |

| Shank Material | Tungsten (W) | √ |

| Steel | √ | |

| Molybdenum (Mo) | √ | |

| Shank Shape | Square or Rectangular | √ |

| Round | √ | |

| Custom Shapes | √ |

To ensure optimal performance and tool longevity, please observe the following guidelines when using ultra-precision diamond cutting tools:

1. Tool Specification Selection

Match Tool Parameters to Workpiece Requirements

Select appropriate tool specifications (radius, rake angle, clearance angle, etc.) according to the material properties and processing requirements of the workpiece. For example, harder or more brittle materials may require a different radius or relief angle to ensure surface quality and avoid chipping.

Select Proper Tool Holder Size and Type

Choose a tool holder that is compatible with your machine’s clamping system. The size, shape, and rigidity of the holder will affect cutting stability and precision. A well-matched holder reduces vibration and ensures better surface finish.

2. Tool Selection Based on Material

For Non-Ferrous Metals

When machining materials such as aluminum, copper, or magnesium alloys, it is recommended to use a tool with 0° rake angle. This neutral angle provides better edge strength and stability, helping to achieve a smooth cutting process and extend tool life.

For Infrared Crystal Materials

When processing hard and brittle infrared optical materials such as ZnSe, Ge, or CaF₂, a tool with a -25° rake angle is preferred. The negative rake angle improves cutting edge strength and reduces the risk of chipping or cracking, ensuring high surface quality and dimensional accuracy.

Additional Recommendations

Always clean the tool and holder before installation to prevent misalignment or tool run-out.

Ensure the machine is operating under stable conditions with minimal vibration.

Avoid excessive cutting forces to maintain edge integrity, especially when using ultra-fine radius tips.

Use suitable coolant or air-blow systems when necessary to control temperature and remove chips.