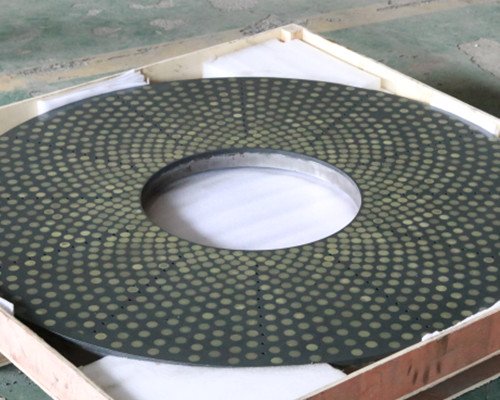

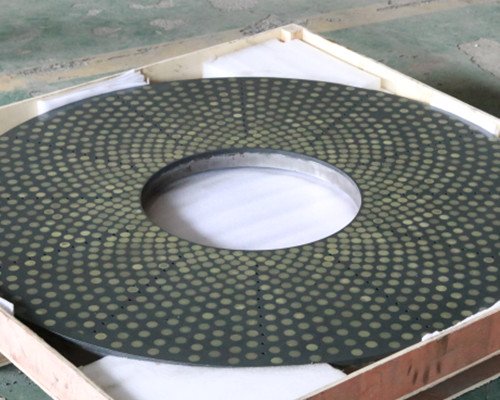

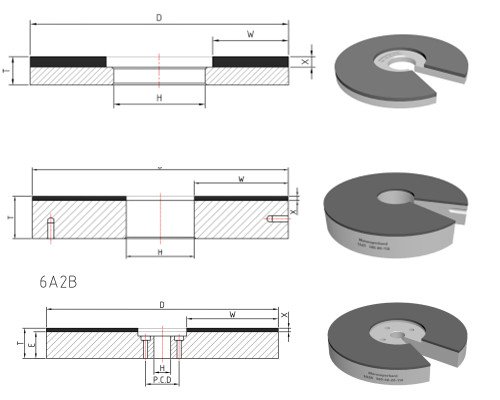

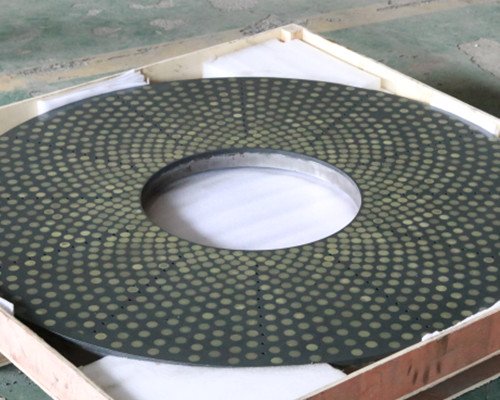

The double-sided ceramic CBN grinding wheel is specifically designed for high-efficiency, high-precision grinding of automotive components such as gears, bearings, and transmission parts.With vitrified bond technology, it provides superior form retention, excellent thermal stability, and long dressing intervals.The dual-face design allows simultaneous grinding of both sides, improving flatness, parallelism, and production throughput.

High Efficiency: Simultaneous double-sided grinding ensures fast material removal and consistent accuracy.

Superior Precision: Excellent surface finish and tight dimensional control for automotive-grade requirements.

Long Service Life: Vitrified bond provides strong grit holding power and outstanding wear resistance.

Stable Performance: Performs reliably under heavy-load, high-speed conditions.

Low Maintenance: Reduced dressing frequency and minimal wheel deformation.

Widely used for grinding precision automotive parts including:

| Grinding Wheel Type | Vitrified Bond (Ceramic) |

|---|---|

| Abrasive Material | CBN (Cubic Boron Nitride) |

| Available Diameter Range | 300–1500 mm (customizable) |

| Available Thickness Range | 20–80 mm (customizable) |

| Grit Size | B46–B151 (coarse to fine) |

| Bond Type | Vitrified / Ceramic Bond |

| Workpiece Materials | Hardened steel, bearing steel, martensitic stainless steel, and other automotive alloys |

| Machine Compatibility | Double-disc grinding machines such as Stahli, Lapmaster, Koyo, and Toyoda |

| Surface Finish | Ra < 0.4 μm (N4 level achievable) |

| Dressing Wheel | WA or silicon carbide dressing wheel |

A leading automotive parts manufacturer used the D1000×T58×H410×t6 mm vitrified CBN double-sided grinding wheel on Stahli and Lapmaster double-disc grinders to process martensitic stainless steel components after heat treatment (45–50 HRC).