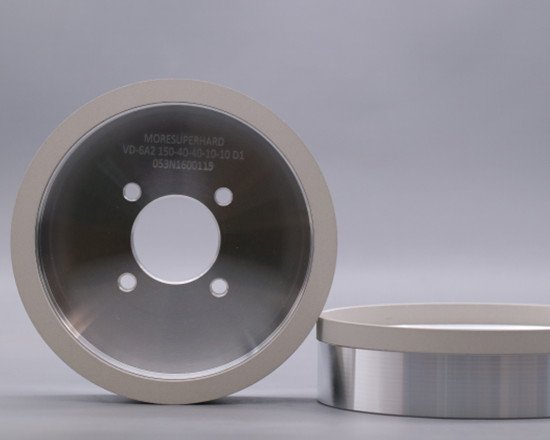

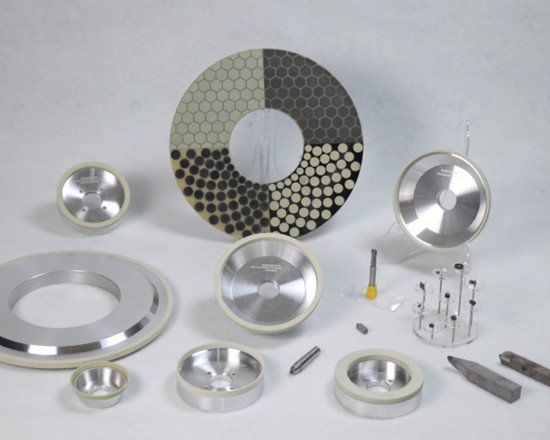

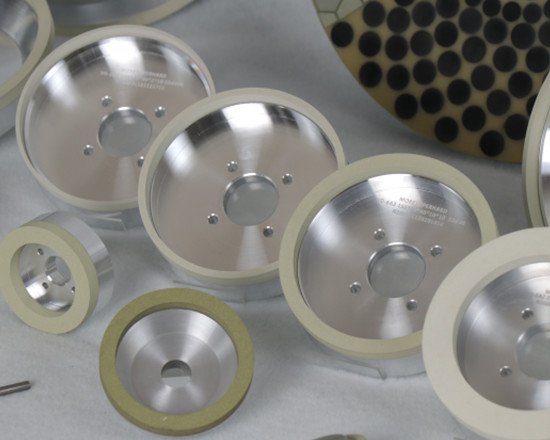

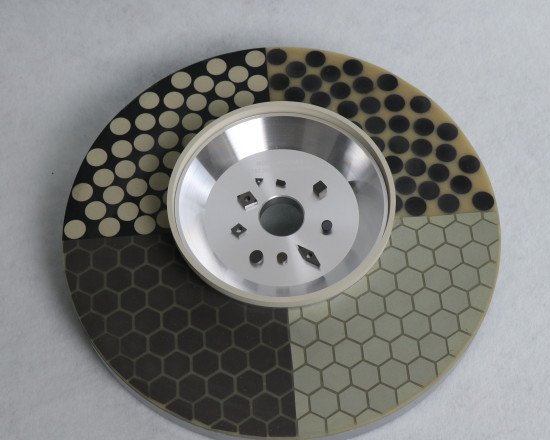

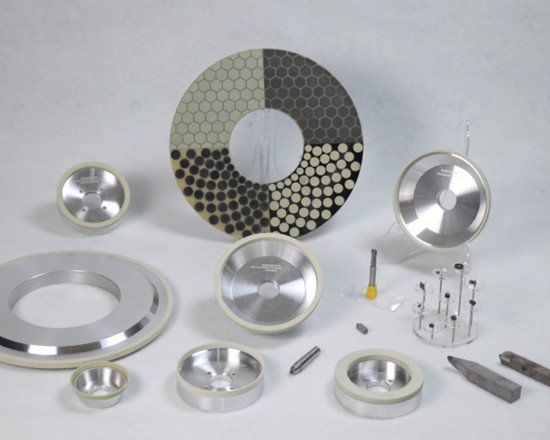

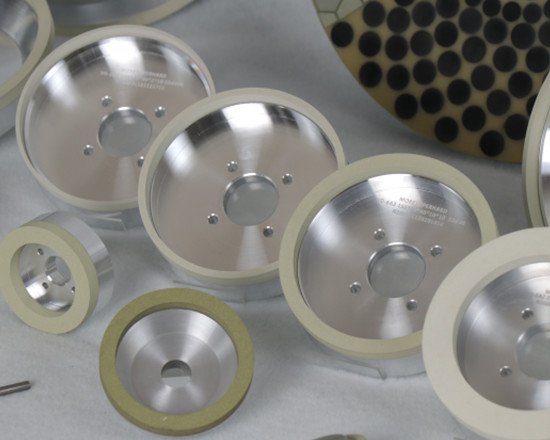

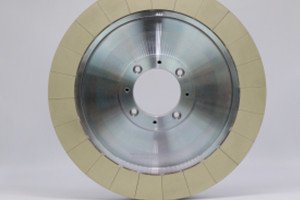

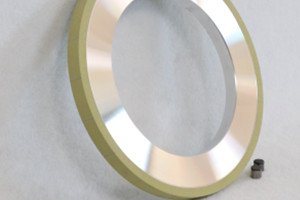

Vitrified diamond grinding wheels combine the hardest known super abrasives held mechanically and chemically in glass (ceramic bond) to form some of the most highly efficient grinding products available on the market. Vitrified bond diamond grinding whee is a kind of circular bonded abrasive with through-hole in the center which made of diamond powder and vitrified (ceramic) bond. Diamond grinding wheel is composed of the diamond layer, transition layer and matrix.

More SuperHard can supply quality vitrified diamond grinding wheel with long life as well as fast cutting. We only choose the very strong synthetic diamond as the raw materials, we make sure not only the particle shape is round enough but also be with some sharp points, which can make sure we won’t lose the efficiency while we still want enough life from the wheels. So it will help you get fast, stable, much more PCD tools in unit time.

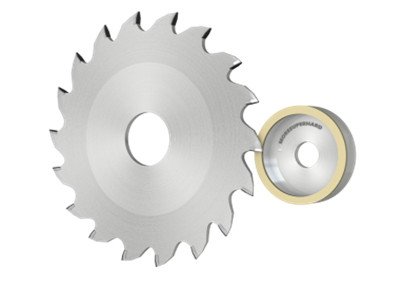

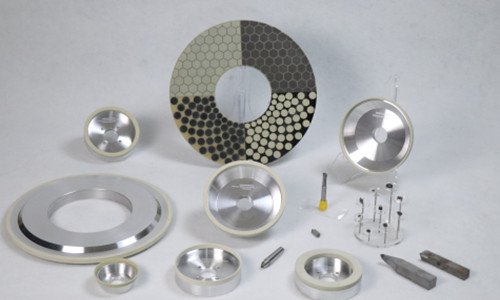

1. Vitrified grinding wheels most commonly employed in the grinding of PCD and PCBN tools and inserts. Cylindrical grinding, surface grinding, regrinding PCD cutting tools, PCBN cutting tools, CVD tools, MCD tools, ceramic tools, cermet tools, milling cutter, reamer, drill, etc.

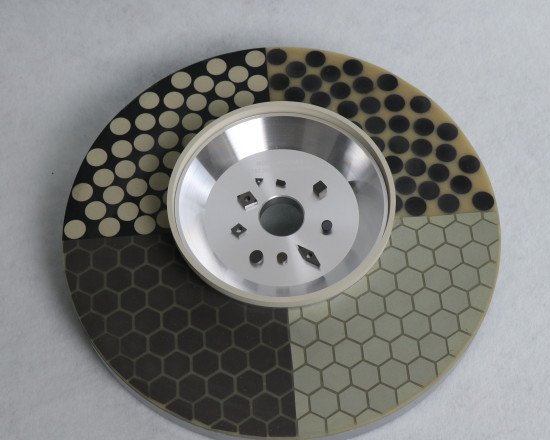

2. Vitrified diamond grinding wheels are used for grinding ceramic workpieces like alumina ceramic sealing rings etc

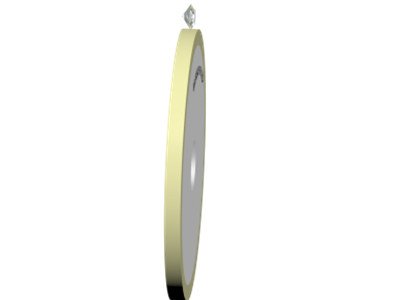

3. Vitrified diamond grinding wheel for back grinding semiconductor materails like single crystal silicon,silicon carbide,sapphire etc.

![]()

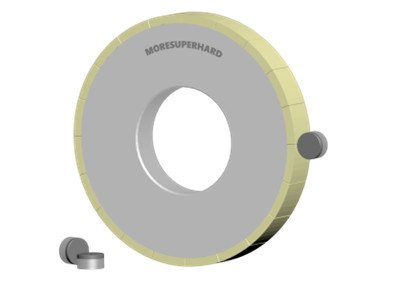

4.Vitrified diamond wheel for grinding and polishing jewelry diamond like natural diamond

5. Vitrified diamond grinding wheel for thermal spraying industry.

Advantages of vitrified diamond wheels

Grain size selection of vitrified diamond grinding wheel

| Grain Size | Machining Type | Application |

| W40(500# D35) W28(D20) | Rough | Regrinding a blade edge profile and sharpening of much worn inserts |

| W20 (800# -1000#, D20) | Universal | Standard grain size also can get a high sharpening efficiency, good quality surfaces |

| W10 (1500# D15A) W7 (2000# D15B) | Finish | Finishing grinding – getting a very good quality of machined surfaces |

| W5 (3000# D7) W3.5 (4000# D3) | Super Finish | Super finish grinding – getting a brilliant quality of machined surfaces |

| Others grits of vitrified diamond wheel can be made according to customers’ requirements. Email: pcd@moresuperhard.com | ||

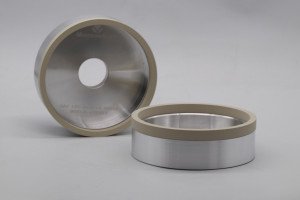

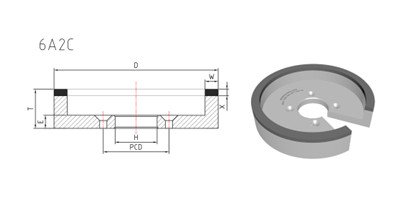

The specifications of vitrified diamond grinding wheels

| Model | D (mm) | T (mm) | H (mm) | W (mm) | X (mm) |

| 6A2 cup wheel | 100 | 40 | 32, 40 | 3, 4, 5, 8,10, 15, 20 | 10 |

| 125 | 40 | 32, 40 | 3, 4, 5, 8,10, 15, 20 | 10 | |

| 150 | 40 | 32, 40 | 1,2,3, 4, 5, 8,10, 15, 20 | 10 | |

|

Other size can be made according to customers requirement. Email: pcd@moresuperhard.com |

|||||

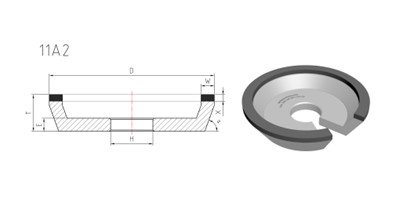

| Model | D (mm) | T (mm) | W (mm) | X (mm) |

| 11A2

grinding wheel

|

50 | 20 | 3, 5, 6 | 2, 3, 4 |

| 75 | 20 | 3, 5, 6, 10 | ||

| 100 | 20 | 3, 5, 6, 8, 10 | ||

| 125 | 23 | 6, 8, 10, 15 | ||

| 150 | 23 | 6, 8, 10, 15 | ||

| 175 | 23 | 6, 10, 15, 20 | ||

| 200 | 23 | 6, 10, 15, 20 | ||

|

Other size can be made according to customer requirements. Email: pcd@moresuperhard.com |

||||

| Model | D (mm) | X (mm) | U (mm) | T (mm) | E (mm) | K (mm) | J (mm) |

| 11V9

grinding wheel

|

50 | 1.5, 2 | 6, 10 | 30 | 10 | 20 | 28 |

| 3 | |||||||

| 75 | 1.5, 2 | 6, 10 | 30 | 10 | 40 | 53 | |

| 3 | |||||||

| 100 | 1.5, 2 | 6, 10 | 35 | 10 | 55 | 75 | |

| 3 | |||||||

| 125 | 1.5, 2 | 6, 10 | 40 | 10, 12 | 75 | 96 | |

| 3 | |||||||

| 150 | 1.5, 2 | 6, 10 | 50 | 10, 12 | 90 | 114 | |

| 3 | |||||||

|

Standard S =70° 45° < S < 70° – possible |

|||||||

|

Model |

D (mm) |

T (mm) |

H (mm) |

X (mm) |

|

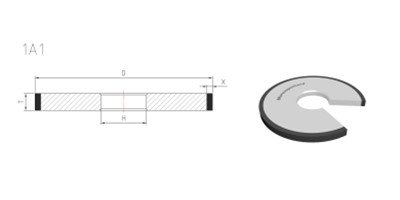

1A1 grinding wheel

|

300 |

20 |

127 |

10 |

|

350 |

20 |

127 |

10 |

|

| 400 |

35 |

154.2 |

10 |

|

|

Other specification can be made according to customer requirement Email:pcd@moresuperhard.com |

||||

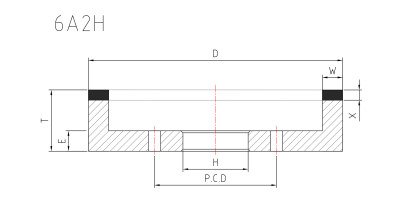

| Model | D (mm) | T (mm) | H (mm) |

6A2/6A2H 6A2/6A2H |

175 | 30, 35 | 76 |

| 200 | 35 | 76 | |

| 350 | 45 | 127 | |

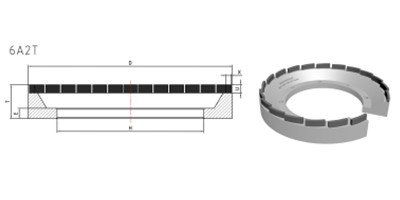

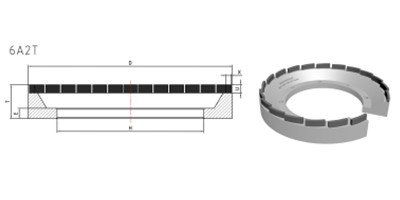

6A2T |

195 | 22.5, 25 | 170 |

| 280 | 30 | 228.6 | |

6A2T(three ellipses) 6A2T(three ellipses) |

350 | 35 | 235 |

| 209 | 22.5 | 158 | |

| Other specifications can be produced according to customers’ requirement. | |||