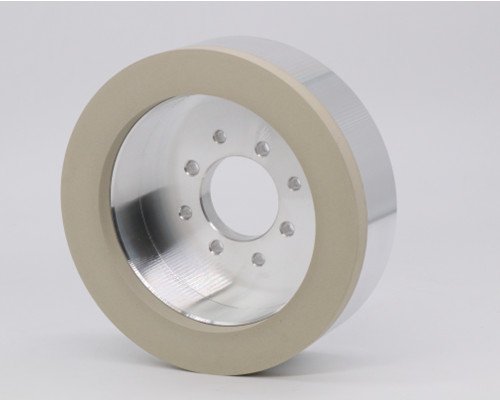

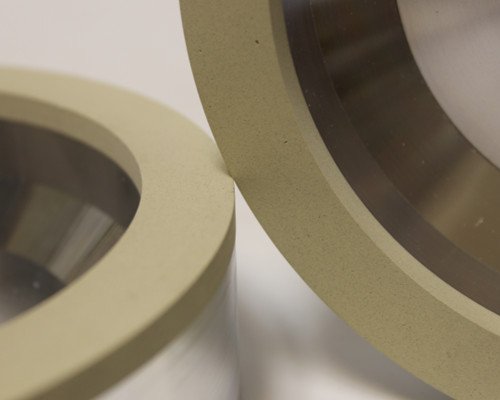

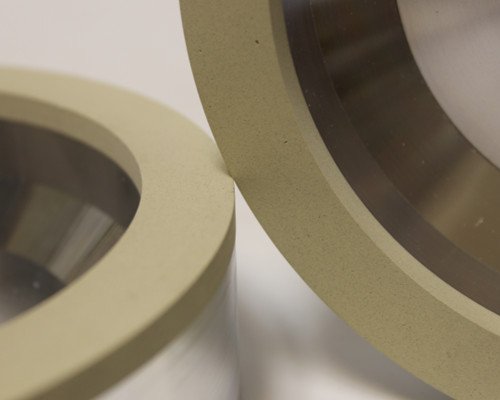

Vitrified diamond cup wheels are used for grinding and regrinding pcd, pcbn, mcd, carbide and ceramic cutting tools. MoreSuperHard devotes to offer an efficiency and economic solution in PCD and CBN cutting tools grinding. We can supply quality PCD grinding wheel at very long life as well as fast cutting. We only choose the very strong synthetic diamond as the raw materials, make sure not only the particle shape is round enough but also be with some sharp points, which can make sure we won’t lose the efficiency while we still want enough life from the wheels. So it will help you get fast, stable, much more PCD tools in unit time.

Applications of vitrified diamond wheels for PCD and PCBN tools

Vitrified bond diamond grinding wheels can be used for grinding PCD PCBN cutting tools, CVD tools, MCD tools, carbide, ceramic cutter, milling cutter, reamer, drill and regrinding, etc.

– PCD (Polycrystalline diamond)

Polycrystalline Diamond is diamond grit that has been fused together under high-pressure, high-temperature conditions in the presence of a catalytic metal. The extreme hardness, wear resistance, and thermal conductivity of diamond make it an ideal material for the cutting tools manufacturing.

– PCBN (Polycrystalline cubic boron nitride)

PCBN is simply an acronym for polycrystalline cubic boron nitride which is used in manufacturing high power and intensity tools. This material is created by binding CBN (cubic boron nitride) particles with specific binders that boost strength and resistance to wear.

– MCD (Mono crystalline diamond)

Mono crystalline diamond (MCD) is also called as synthetic single crystal diamond (SCD). It is synthetic diamonds produced by high pressure high -temperature synthesis under tightly controlled growth conditions.

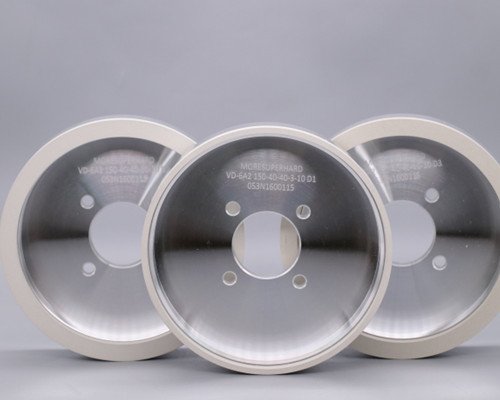

PCD Grinding Machine: Coborn, Ewag, Anca, Farman, Mytech

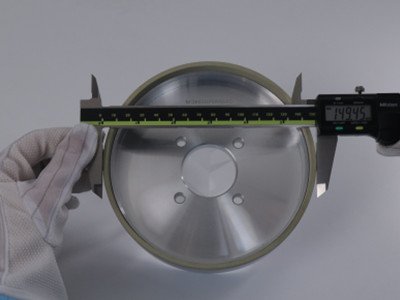

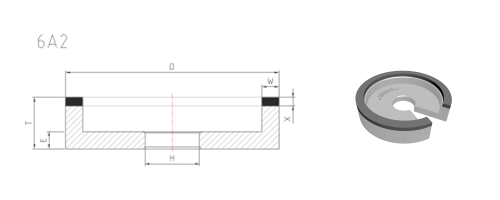

| Model | D (mm) | T (mm) | H (mm) | W (mm) | X (mm) |

| 6A2 | 100 | 40 | 32, 40 | 3, 4, 5, 10, 15, 20 | 10 |

| 125 | 40 | 32, 40 | 3, 4, 5, 10, 15, 20 | 10 | |

| 150 | 40 | 32, 40 | 1, 2, 3, 5, 10, 15, 20 | 10 | |

| Grit: 325/400, W40 (500#), W28 (600#), W20 (800#), W10 (1500#), W5 (3000#), W3 (5000#)

Other size can be made according to customer’s requirement. Email: pcd@moresuperhard.com |

|||||

| Grain Size | Machining Type | Application |

| W40(500# D35) W28(D20) | Rough | Regrinding a blade edge profile and sharpening of much worn inserts |

| W20 (800# -1000#, D20) | Universal | Standard grain size also can get a high sharpening efficiency, good quality surfaces |

| W10 (1500# D15A) W7 (2000# D15B) | Finish | Finishing grinding – getting a very good quality of machined surfaces |

| W5 (3000# D7) W3.5 (4000# D3) | Super Finish | Super finish grinding – getting a brilliant quality of machined surfaces |

| W1.5(10000# D1) | Ultra Finish | Better surface finish, avoid edge collapse |

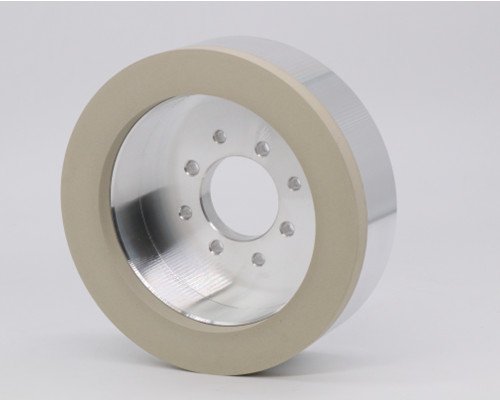

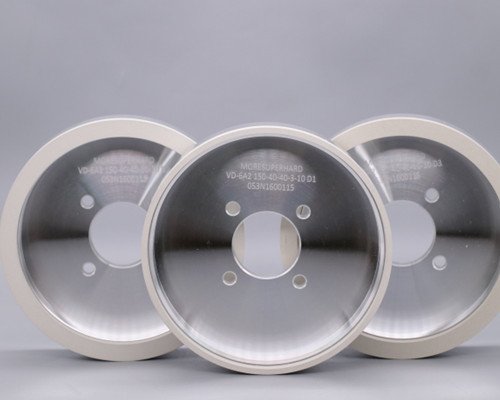

New Products – “533” “053” Vitrified Diamond Wheel

“533” is ultra-precision grinding wheel with particle size of 3μm, “053” is ultra-precision grinding wheel with particle size of 1μm. It can achieve very high surface finish, good self-sharpening and high grinding efficiency. Specially used for ultra-high precision PCD/PCBN tool grinding.

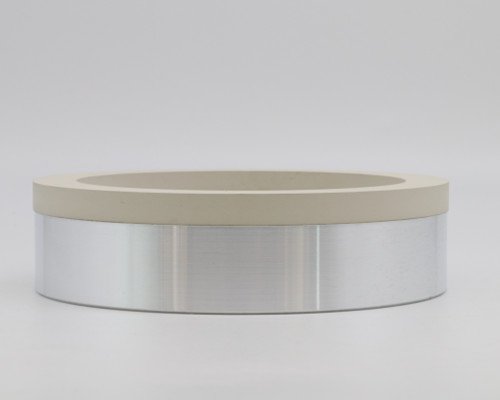

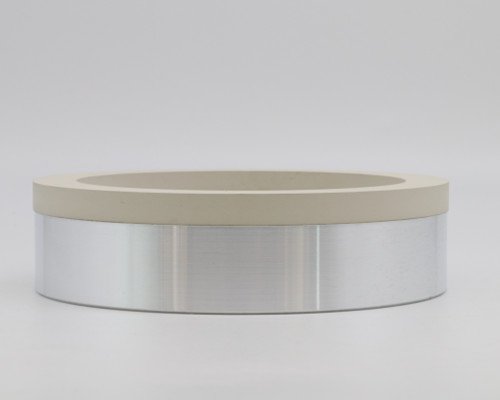

MoreSuperHard specially developed ultra-narrow vitrified diamond grinding wheel with 1 mm width, to meet the needs of customers for ultra-small size PCD, PCBN tools grinding.

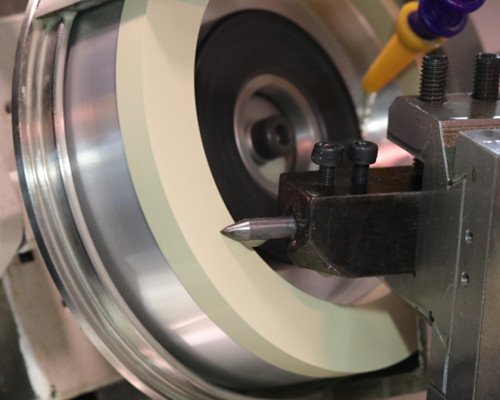

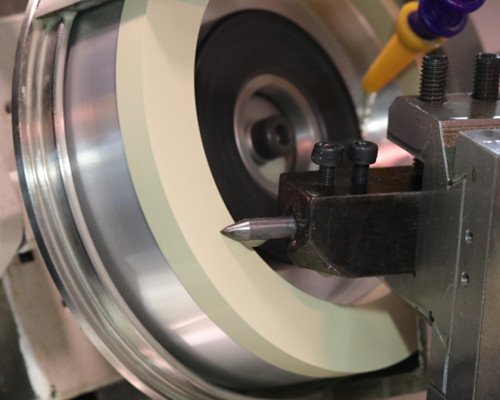

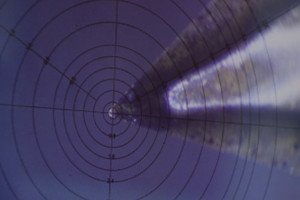

Dressing of vitrified diamond grinding wheel for PCD and PCBN tools

In order to improve the efficiency of grinding wheels, MoreSuperHard independently developed a vitrified diamond dressing wheel specially used for dressing vitrified diamond grinding wheels for PCD tools. At present, it has been put into production and supplied to the market.