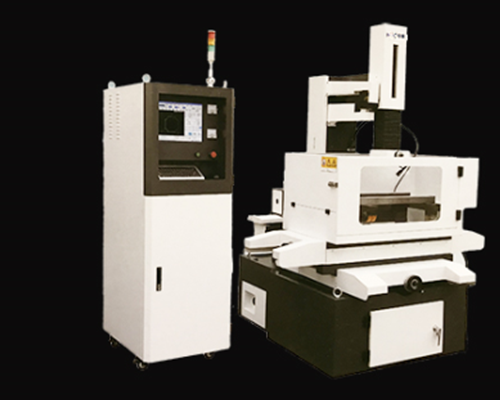

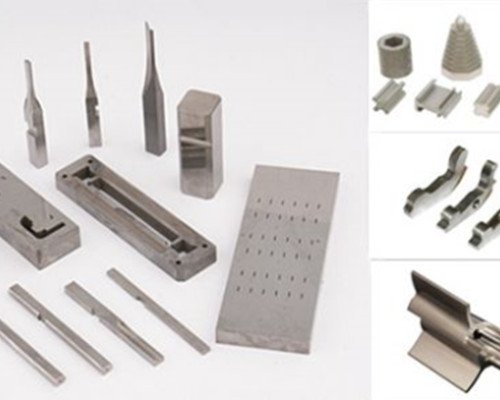

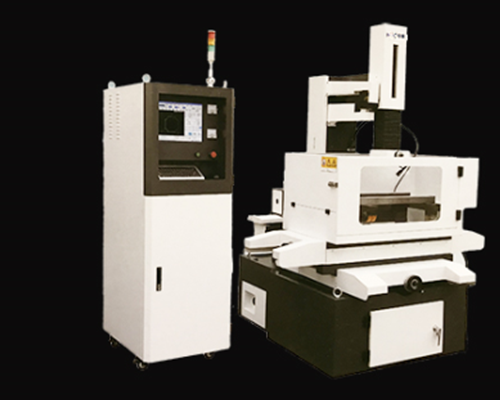

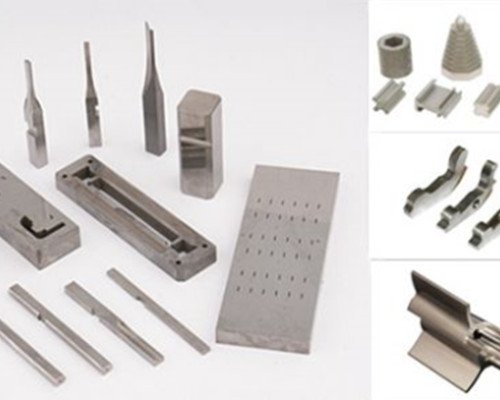

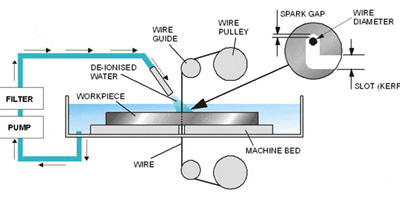

Wire Cut EDM, also known as (wire electrical discharge machining or wire EDM) is a high-precision method for cutting nearly any electrically conductive material. A thin, electrically-charged EDM wire held between upper and lower mechanical guides forms one electrode, while the material being cut forms the second electrode. Electrical discharge between the wire and the workpiece creates sparks that rapidly cut away materials.

| Item | DK series | |||||

| Travel of X/Y(mm) | 250*320 | 320*400 | 400*500 | 500*630 | 630*800 | |

| Max. Cut thickness (mm) | 300 – 500 | |||||

| Cut taper/thickness °/mm | ±3° or ±30°/100 | |||||

| Cut accuracy mm | ≤0.015 | |||||

| Max. cut speed mm2/min | 160 | |||||

| Best finish | Once cutting Ra ≤ μm | ≤2.5 | ||||

| Multi cutting Ra ≤ μm | ≤1.5 | |||||

| Wire diameter mm | 0.12-0.25 | |||||

| Max. electrical current A | 6 | |||||

| Voltage V/Hz | 3 phase 380V/50Hz or 220V/60Hz or 415V/50Hz | |||||