Key Features

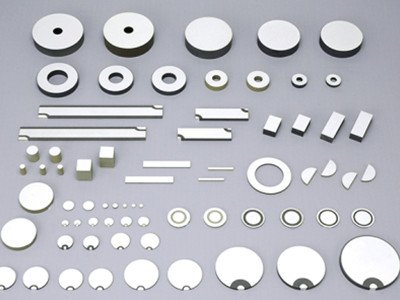

- High piezoelectric sensitivity and efficient energy conversion

- Strong ferroelectricity and high dielectric constant

- Adjustable properties via Zr/Ti ratio or dopants

- Good thermal stability and wide operating temperature range

Grinding Challenges of PZT Ceramics

PZT is hard and brittle. Improper machining can cause edge chipping, microcracks, low grinding efficiency, and poor surface quality. Selecting the right grinding wheel is essential for material integrity and desired surface finish.

Recommended Grinding Wheels for PZT Ceramic Machining

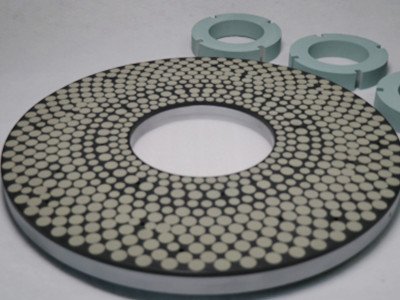

1. Resin-Bond Diamond Grinding Wheels

Resin bond wheels provide elasticity and smooth cutting action. Their slight polishing effect helps deliver superior surface finish while minimizing subsurface damage.

Advantages: Excellent surface finish; lower grinding forces; suitable for brittle materials.

Best for: Fine grinding, polishing, and low-damage finishing.

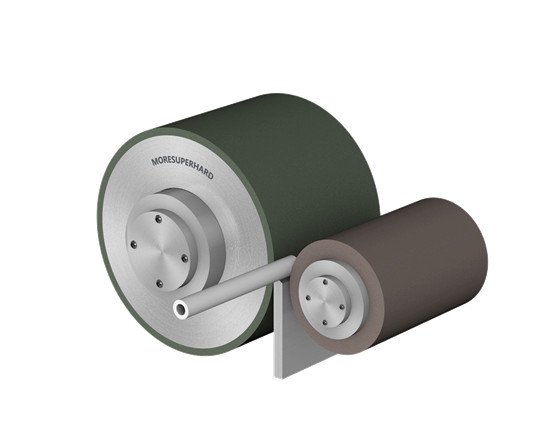

2. Vitrified (Ceramic-Bond) Diamond Grinding Wheels

Vitrified wheels are hard, wear-resistant, and thermally stable. They maintain shape over long cycles and offer strong self-sharpening ability for stable cutting performance.

Advantages: Superior form retention; high grinding efficiency; good for automated or continuous grinding.

Best for: Precision grinding, profile grinding, and medium-to-high feed operations.

3. Electroplated Diamond Grinding Wheels

Electroplated wheels expose a high proportion of abrasive, providing very sharp cutting action and high removal efficiency. They typically require no dressing and offer excellent initial precision.

Advantages: Fast cutting; high abrasive exposure; no dressing required.

Best for: High-precision cutting, heavy stock removal, and complex geometries.

Grinding Wheel Selection Strategy for PZT

- Material removal rate: coarse grit + harder bond for roughing

- Surface quality: fine grit + resin or vitrified wheels for finishing

- Thermal sensitivity: control heat to avoid microcracks

- Dimensional accuracy: vitrified wheels preferred for form stability

Summary Comparison

| Grinding Wheel Type | Advantages | Typical Use |

|---|---|---|

| Resin-bond diamond | Best finish, elastic cutting action | Fine grinding, polishing |

| Vitrified (ceramic-bond) diamond | High stability and form accuracy | Precision and profile grinding |

| Electroplated diamond | Sharpest cutting, no dressing | Cutting, heavy removal, micro-machining |