30

Apr

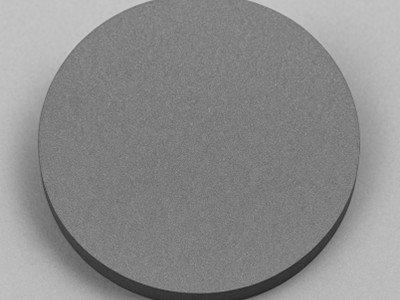

Silicon carbide ceramic (SiC ceramic) is a high-performance ceramic material with silicon carbide as the main component. It is widely used in the industrial field for its excellent physical and chemical properties. Because of its high hardness, high strength and high brittleness, it becomes a difficult-to-process material.

To grind silicon carbide ceramic, you can choose diamond grinding wheel as a grinding tool. According to the characteristics of different binders, combine your own equipment and processing technology to select the appropriate tool grinding wheel.

For processing silicon carbide ceramic grinding wheel, the binder can be electroplated, resin, ceramic, and metal. The following are the characteristics of various binders.

Electroplated diamond grinding wheel: A grinding tool that is electroplated and consolidated with a layer of diamond abrasive on the surface of a metal matrix. Its advantages are: high sharpness, high initial precision, can be made into various non-standard shapes, and no need for dressing; disadvantages are: lower life than consolidated diamond grinding tools, slightly poor surface quality, and cannot be made into ultra-fine grains. It is suitable for a wide range of grinding methods.

Resin-bonded diamond grinding wheel: a bonded abrasive made of resin material mixed with diamond abrasive. Its advantages are: elasticity, excellent surface quality of the processed surface, low ceramic edge collapse rate, and easy dressing; Disadvantages: general shape retention. Suitable for most grinding methods such as surface grinding, cylindrical grinding, and internal grinding.

Vitrified diamond grinding wheel: a bonded abrasive made of ceramic material mixed with diamond abrasive. Its advantages are: high hardness, good wear resistance and shape retention, high sharpness, and easy dressing; Disadvantages: coarse-grained grinding of ceramics is prone to edge collapse and cannot make complex surfaces.

Generally used for surface grinding and cylindrical grinding.

Metal-bonded diamond grinding wheel: a bonded mold made of metal material mixed with diamond abrasive. Its advantages: high hardness, wear resistance and shape retention are the best among bonded abrasives, such as electroplated diamond grinding wheels, which generally support various non-standard complex surfaces (but can only make rough contours and require terminal finishing); Disadvantages: difficult to dress, and not as sharp as ceramics. Applicable to a wide range of grinding methods.

When choosing a grinding wheel, you can choose the corresponding binder according to the above advantages and disadvantages based on the compatibility of your own equipment and process. In addition, according to the processing steps, there are generally coarse and fine grinding. Choose the appropriate particle size to increase efficiency and achieve the roughness required by the process.

There is a corresponding reference for particle size comparison, and you can choose according to the particle size comparison table. However, the coarser the particle size, the sharper the grinding wheel, and the finer the particle size, the opposite is true. You can’t have both fish and bear’s paw. It needs to be tested and adapted to the working conditions to achieve the ideal state.