04

Jan

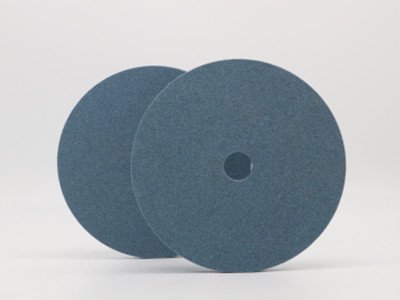

In the field of precision machining, resin bond diamond grinding wheels are widely used as essential tools for processing hard and brittle materials such as cemented carbide and ceramics, thanks to their good cutting performance and controlled self-sharpening behavior. However, many manufacturers still encounter issues such as excessive grinding heat, workpiece burn, and low machining efficiency during actual production. In most cases, these problems can be traced back to the neglect of wheel opening before use and proper dressing during operation.

Resin diamond grinding wheel Initial dressing and dressing/truing are not auxiliary operations, but critical processes that directly affect cutting performance, machining stability, and wheel service life. This article provides a systematic analysis of the principles, methods, and practical value of opening and dressing resin bond diamond grinding wheels, helping manufacturers improve machining accuracy and overall productivity.

The performance of resin bond diamond grinding wheels is derived from the interaction between diamond abrasives and the resin bond. The resin bond exhibits a certain degree of elasticity, which helps absorb local impact loads during grinding and reduces the risk of edge chipping on the workpiece. Under appropriate grinding conditions, the bond gradually wears as abrasive grains become dull, allowing new diamond cutting edges to be exposed and maintaining a relatively stable cutting behavior.

It should be noted that the so-called “self-sharpening” of resin bond wheels does not occur automatically. Instead, it depends on proper grinding parameters, load conditions, and dressing practices. Under unsuitable conditions, resin bond wheels can still suffer from glazing and loss of cutting efficiency.

A common misconception in the industry is that “a new grinding wheel is ready for optimal use.” In reality, the diamond grains of a newly manufactured resin bond wheel are usually fully embedded in the bond matrix, and effective cutting edges have not yet been formed. If such a wheel is put into operation directly, the grinding process tends to be dominated by friction rather than cutting, leading to low efficiency and excessive heat generation.

Wheel opening (Initial dressing) refers to a controlled process that removes a portion of the resin bond covering the diamond grains, allowing the abrasive tips to protrude and form effective cutting edges. In simple terms, Initial dressing activates a new grinding wheel and enables it to perform proper cutting.

In a new wheel, the resin bond securely holds the diamond abrasives to maintain structural integrity. However, this protective layer also covers the cutting edges of the abrasives. Without Initial dressing, the contact between the wheel and the workpiece is closer to surface rubbing rather than edge cutting. As a result, material removal becomes inefficient, while frictional heat increases significantly. Typical consequences of using an unopened wheel include burn marks on cemented carbide surfaces, deterioration of surface integrity, and accelerated thermal damage to the grinding wheel itself, which may ultimately render the wheel unusable.

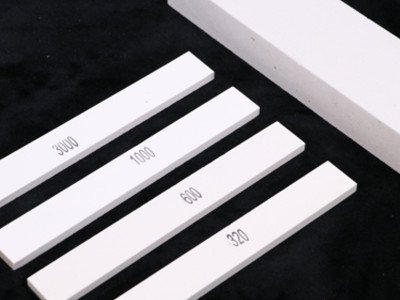

Several proven opening methods are commonly used in industrial practice, and the selection should be based on wheel size, bond hardness, and application requirements:

![]()

The effectiveness of Initial dressing mainly depends on wheel speed, feed rate, and contact mode. Excessively high speed may soften the resin bond due to heat, reducing opening efficiency. Feed should be light and gradual to prevent abrasive pull-out. Progressive contact—from point to line to surface—is recommended to ensure uniform exposure of diamond grains.

Practical indicators of successful opening include stable cutting without slippage, clear cutting sound, absence of burn marks on the workpiece, and smooth chip evacuation.

Initial dressing and dressing are closely related but serve different stages of wheel use. Opening is mainly applied to new wheels, while dressing is a maintenance process performed during grinding operations. Dressing serves two primary purposes:

Without timely dressing, a resin bond wheel may gradually lose sharpness, resulting in increased grinding forces and thermal load. Conversely, excessive dressing leads to unnecessary abrasive consumption and reduced wheel life.

Dressing methods for resin bond diamond grinding wheels can be broadly divided into two categories:

Different materials require different dressing strategies. For cemented carbide grinding, soft dressing with aluminum oxide blocks can balance efficiency and wheel life. For ceramic materials, a combination of mechanical and soft dressing is often recommended.

Dressing frequency should be optimized based on grinding sound, surface finish, and chip behavior rather than fixed intervals.

Correc tInitial dressing and regular dressing of resin bond diamond grinding wheels deliver significant benefits:

Initial dressing and dressing of resin bond diamond grinding wheels are not optional procedures, but essential processes that determine machining accuracy, stability, and cost efficiency. By abandoning improper practices and adopting scientifically optimized opening and dressing methods tailored to specific applications, manufacturers can fully exploit the performance potential of resin bond diamond grinding wheels and achieve efficient, stable, and cost-effective precision machining.