20

Sep

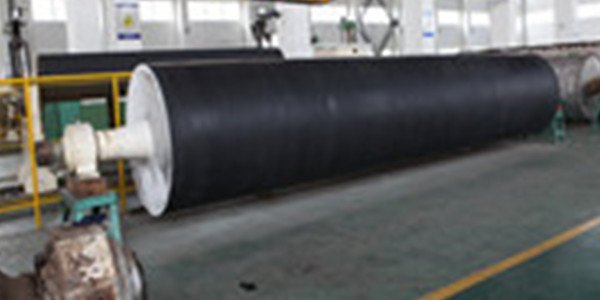

The grinding technology of rubber rollers refers to the process of precision machining of rubber rollers through grinding technology. Rubber rollers are widely used in printing, papermaking, textile, steel and other industrial fields, mainly used in material transmission, calendering, coating and other production links. Therefore, the surface quality and dimensional accuracy of rubber rollers have a vital impact on production efficiency and product quality.

Material elastic deformation: Rubber is a highly elastic material, which will produce elastic deformation during the grinding process, making it difficult to control the processing size and ensure the surface accuracy.

Thermosensitivity: Rubber materials are prone to frictional heat during the grinding process. Excessive temperature may cause aging, hardening, and even burns on the rubber surface.

Grinding force control: Rubber has high toughness and it is difficult to maintain stable grinding force, which makes it difficult to control grinding accuracy and surface quality.

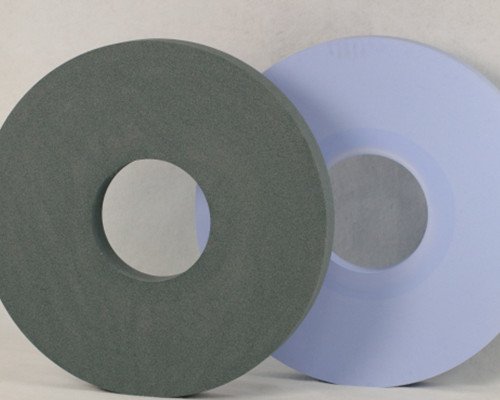

Grinding tool selection: Due to the particularity of rubber materials, resin diamond or silicon carbide grinding wheels with large pores are required to avoid the problem of grinding wheel clogging that may occur during the grinding process.

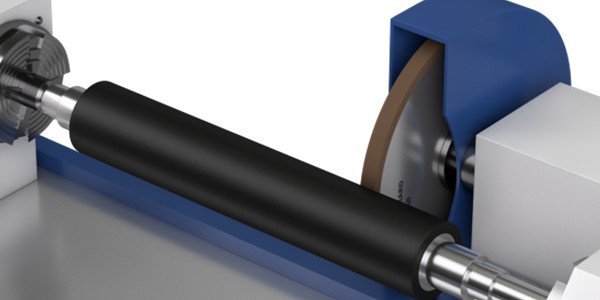

Grinding machine selection: Commonly used rubber roller grinding machines include ordinary lathes and special grinders, which need to be equipped with corresponding cooling systems to reduce the grinding temperature.

Grinding wheel selection: Special rubber grinding wheels should be selected for rubber roller grinding, usually soft grinding wheels with larger pores or diamond grinding wheels with special coatings. These grinding wheels can effectively avoid blockage and heat accumulation.

Application of coolant: In rubber roller grinding, it is necessary to use coolant, and low-temperature coolant is usually used to effectively prevent rubber from deformation or aging due to temperature increase.

Processing parameter control: In order to ensure grinding accuracy, lower cutting speeds and smaller feed rates are usually used, and the grinding force should be closely monitored to prevent excessive elastic deformation.

1. Printing roller grinding

In the printing industry, rubber rollers need to have extremely high surface finish and precision to ensure uniform transmission of ink during printing. In printing enterprises, they used Moresuperhard’s special diamond grinding wheel to grind rubber rollers, and cooperated with precision CNC grinders and cooling systems to effectively solve the elastic deformation and temperature rise problems of rubber rollers. The surface roughness of the rubber rollers finally processed reached Ra 0.8 μm, which greatly improved the printing quality.

2. Grinding of conveyor rollers in steel plants

Rubber rollers are widely used in the process of steel plate transmission in steel plants. This type of rubber roller not only requires high wear resistance, but also requires its surface to have precise dimensional stability. In a steel plant, Moresuperhard’s high-efficiency grinding wheel was used to minimize the hardening and deformation problems of the rubber roller surface by optimizing the grinding speed and feed rate, extending the service life of the rubber roller and improving the transmission accuracy.

3. Grinding of textile rollers

Rubber rollers in the textile industry need to withstand large compression forces and maintain a high surface finish. A textile plant successfully improved the surface accuracy of textile rubber rollers by using Moresuperhard diamond grinding wheel grinding technology, giving them a longer service life and reducing downtime during production.

The grinding technology of rubber rollers plays an important role in many industries. By rationally selecting grinding tools, controlling processing parameters, and combining effective cooling technology, the technical problems in rubber roller grinding can be effectively solved, and product quality and production efficiency can be improved. In the future rubber roller processing, further improving the accuracy and efficiency of grinding technology will drive more efficient development in various industries.